Inter-equipment fiber conveying device

A technology of conveying device and equipment room, which is applied in the field of fiber conveying device between equipment to achieve the effects of convenient maintenance, increased output and increased profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

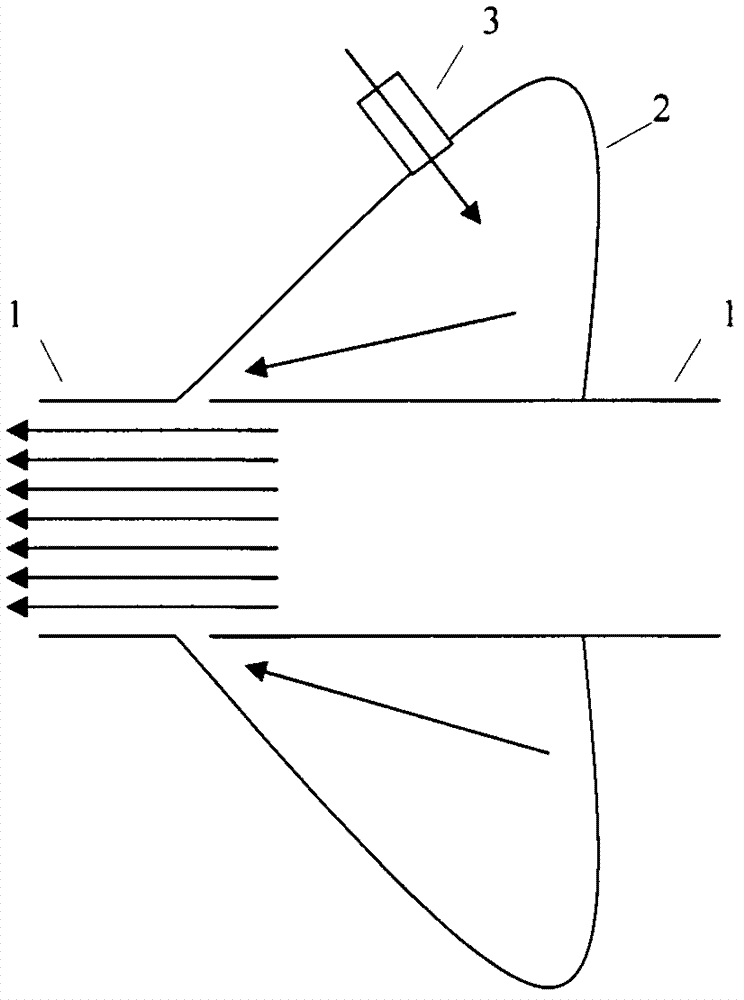

[0015] exist figure 1 In the middle, the high-pressure airflow enters the airflow directional conveyor (2) from the high-pressure airflow inlet (3), and the high-speed airflow is ejected from the 1mm outlet formed with the pipe, which produces a 15-fold amplification effect and forms a powerful airflow in the pipe (1). Fibers convey airflow.

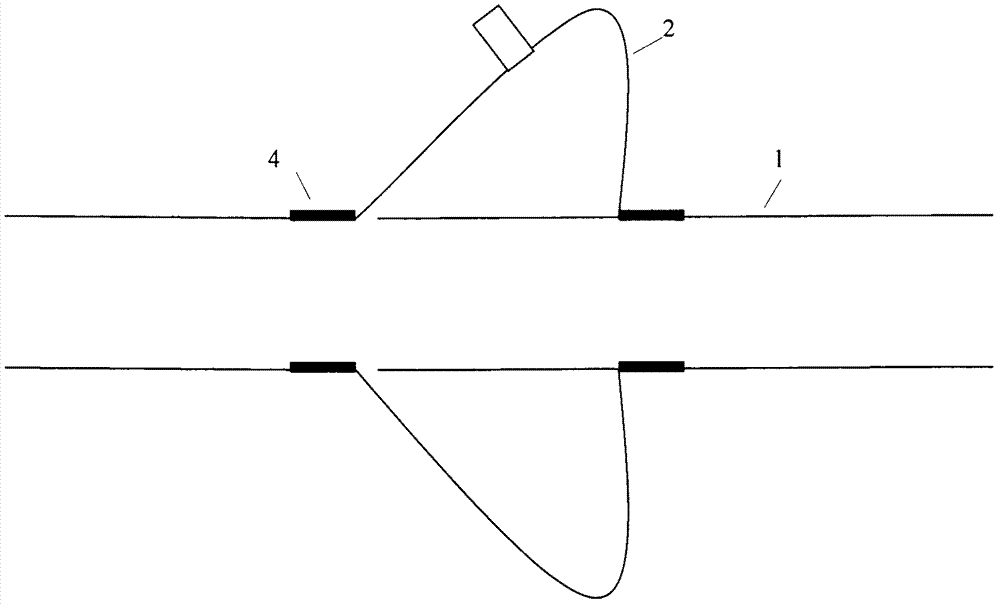

[0016] exist figure 2 Among them, the fiber conveying device between equipment is set on the pipeline (1) by the airflow directional conveyor (2), the 1mm outlet formed by the airflow directional conveyor (2) and the pipeline (1), and the sealing ring (4) realizes the airflow directional conveyor (2) The tightness ensures that the airflow is ejected from the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com