Induction cooker coil plate bracket

A technology for coil discs and induction cookers, which is applied to coil devices, household stoves/stoves, electric heating fuels, etc., can solve the problems of inconsistent relative distances, changes in relative distances, and deterioration of the electrical performance of induction cookers, and achieves uniform and stable distances. Stable electrical performance, good for ventilation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

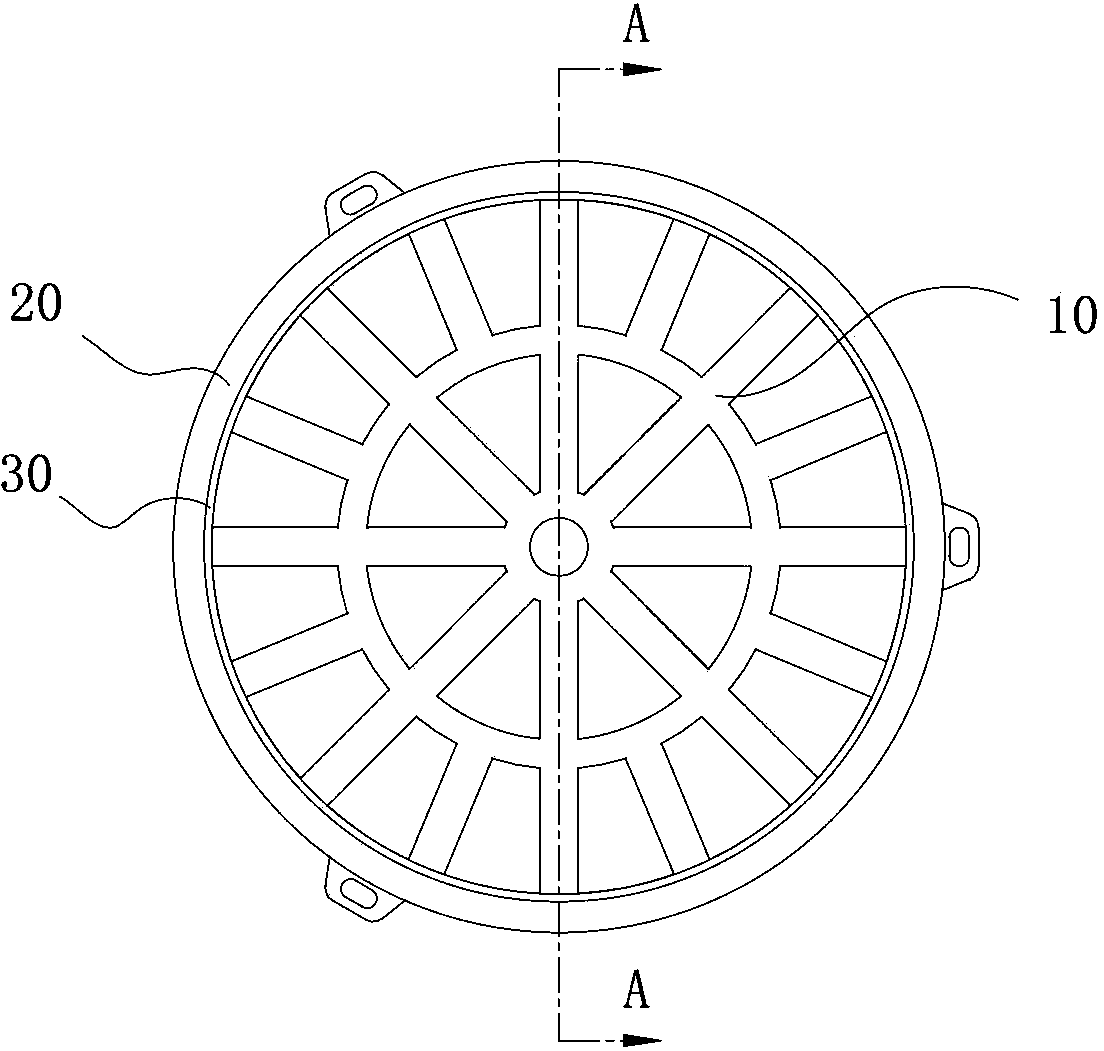

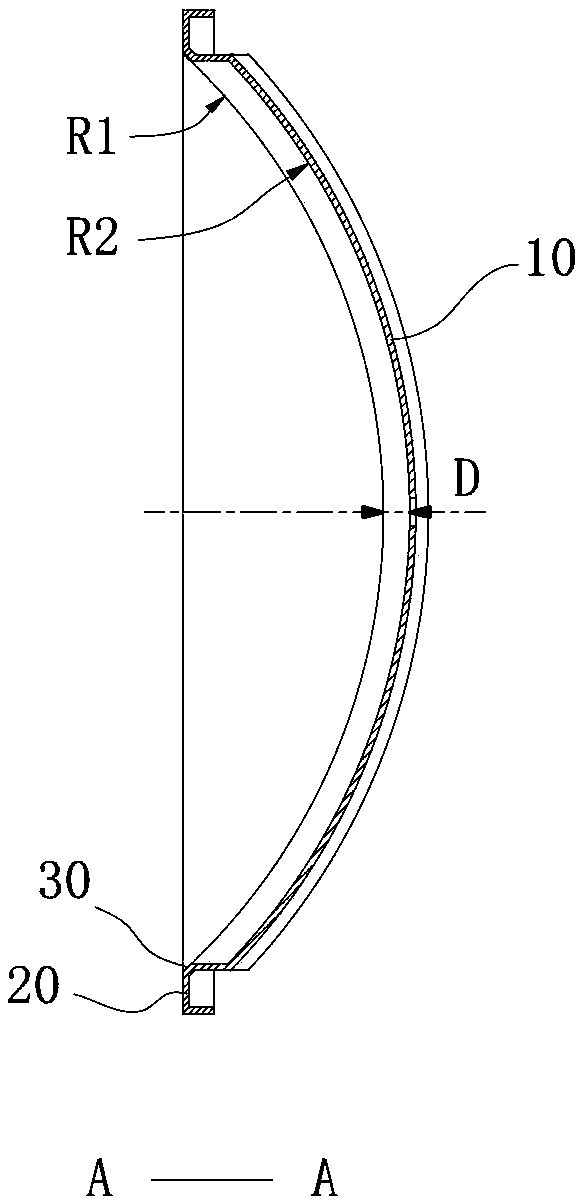

[0027] Such as figure 1 , Figure 2A , Figure 2B As shown, the coil disc support for an induction cooker according to Embodiment 1 of the present invention includes an inner coil disc 10 for arranging a coil winding 100 and an outer ring 20 located outside the inner coil disc 10 . Wherein, the upper end surface of the outer ring 20 is a plane, and an outer ring slope 30 for limiting the distance between the coil winding 100 and the microcrystalline plate 200 is provided at the connection between the inner surface of the inner ring disc 10 and the outer ring 20, and the inner ring disc 10 Both the inner surface and the bevel 30 of the outer ring are curved surfaces. Preferably, the inner surface of the inner ring disc 10 and the bevel 30 of the outer ring are both spherical surfaces with the same spherical center, and the radius R2 of the spherical crown of the inner ring disc 10 is greater than that of the bevel of the outer ring The spherical cap radius R1 of 30, and the r...

Embodiment 2

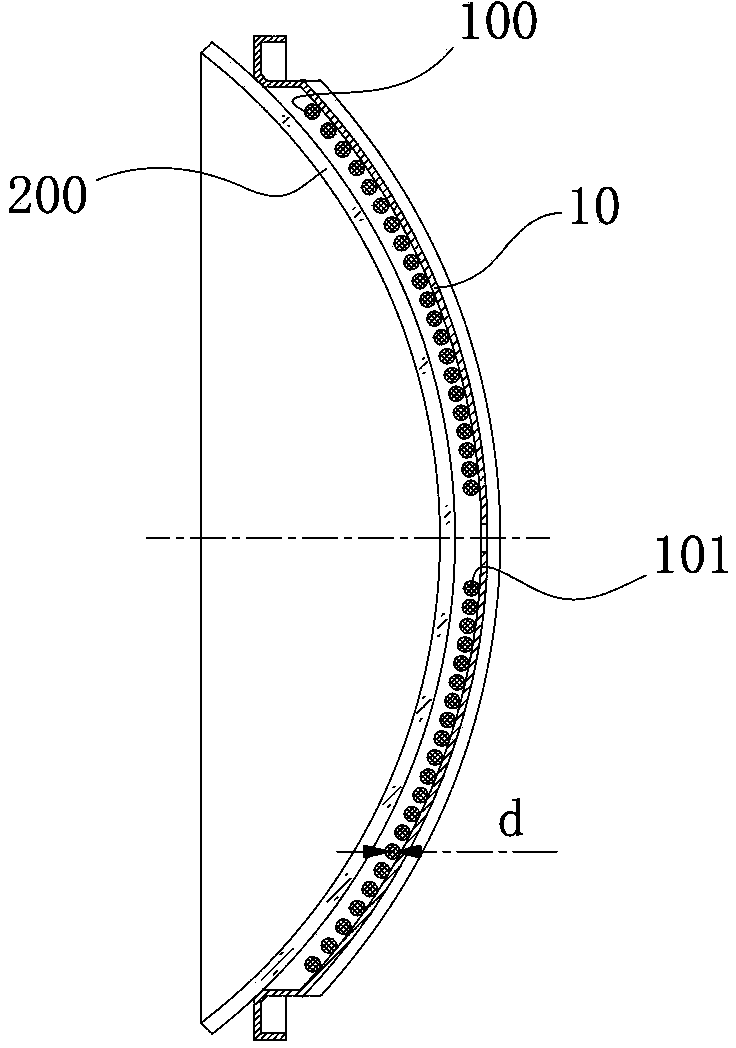

[0030] combine figure 1 and image 3 , Figure 4 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that several grooves 11 are provided on the inner ring disc 10, and magnetic strips 12 are arranged in the grooves 11, and magnetic strips 12 are arranged on the grooves 11. Pressing plate 13 on bar 12 top. Specifically, the groove 11 is a U-shaped groove, the width of the U-shaped groove is greater than the width of the magnetic strip 12, the distance from the bottom of the U-shaped groove to the pressing plate 13 is greater than the thickness of the magnetic strip 12, and the distance between the magnetic strip 12 and the groove 11 Filled with binder. Now ensure that the width of the U-shaped groove 11 is slightly greater than the width of the magnetic strip 12; the groove 11 is fixedly provided with a pressing plate 13 positioned at the top of the magnetic strip 12, and the distance from the bottom of the U-shaped groove 11 to the pressing pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap