Automatic sorting and feeding equipment for sensor shells

A sensor housing, automatic sorting technology, applied in vibration conveyors, climate change adaptation, conveyor objects, etc., can solve problems such as jamming and poor uniformity, achieve uniform and stable distance, and increase convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

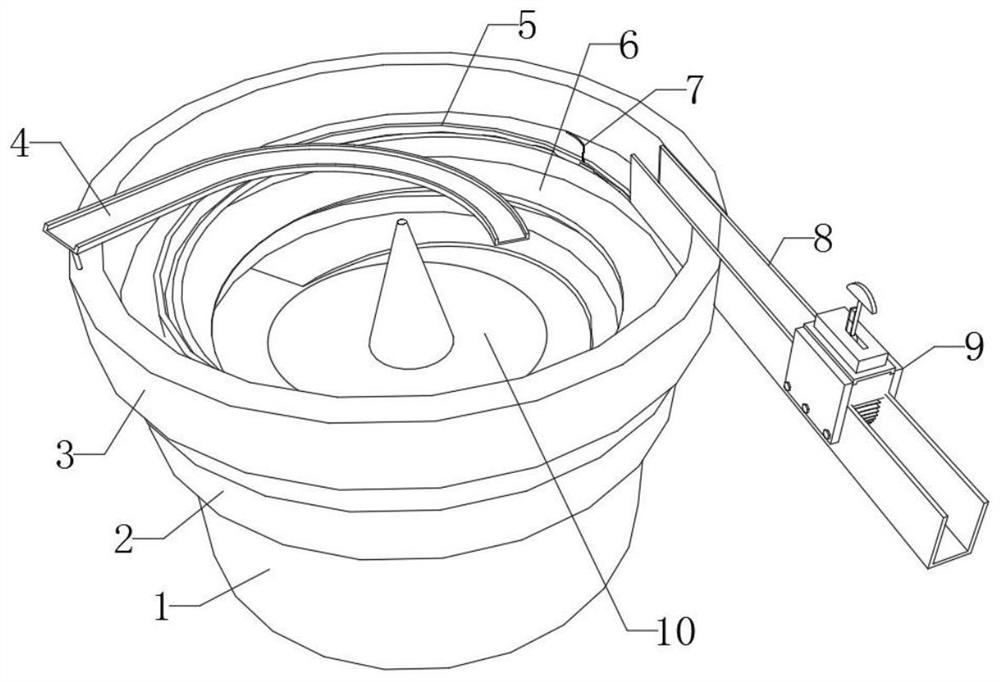

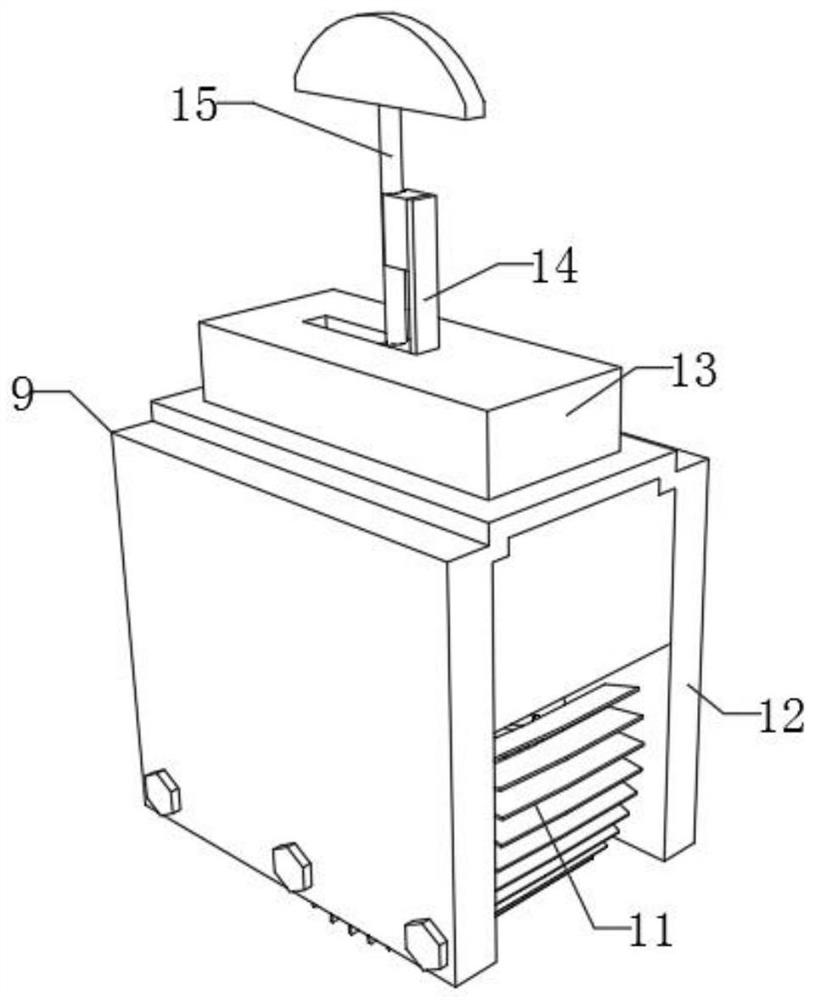

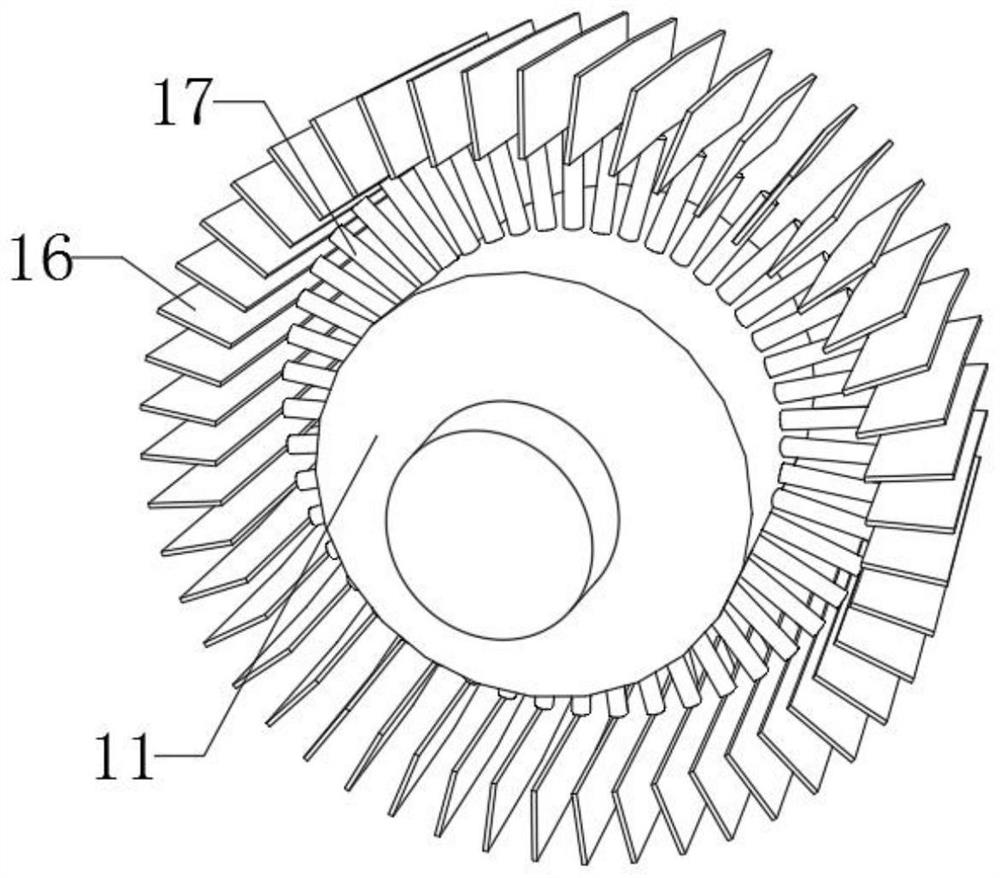

[0025] like Figure 1-Figure 6 As shown, the sensor housing automatic sorting and feeding device provided in this embodiment includes a base 1, and a pulse electromagnet is arranged inside the base 1, which can make the base 2 and the top plate 3 vibrate in the vertical direction at the same time, and the base 1 There is an inclined spring plate connected with the chassis 2. Both ends of the spring plate are connected to the base 1 and the chassis 2 through bolts. The spring plate drives the chassis 2 and the top plate 3 to vibrate around the axis, and the parts in the hopper are subjected to vibration. The feeding tray 6 rises along the spiral, and the top of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap