Barrier cable gland

A technology of cable sealing and cable sheathing, which is applied to the installation of cable terminals, cable accessories, and cables, and can solve problems such as the trouble of applying liquid resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

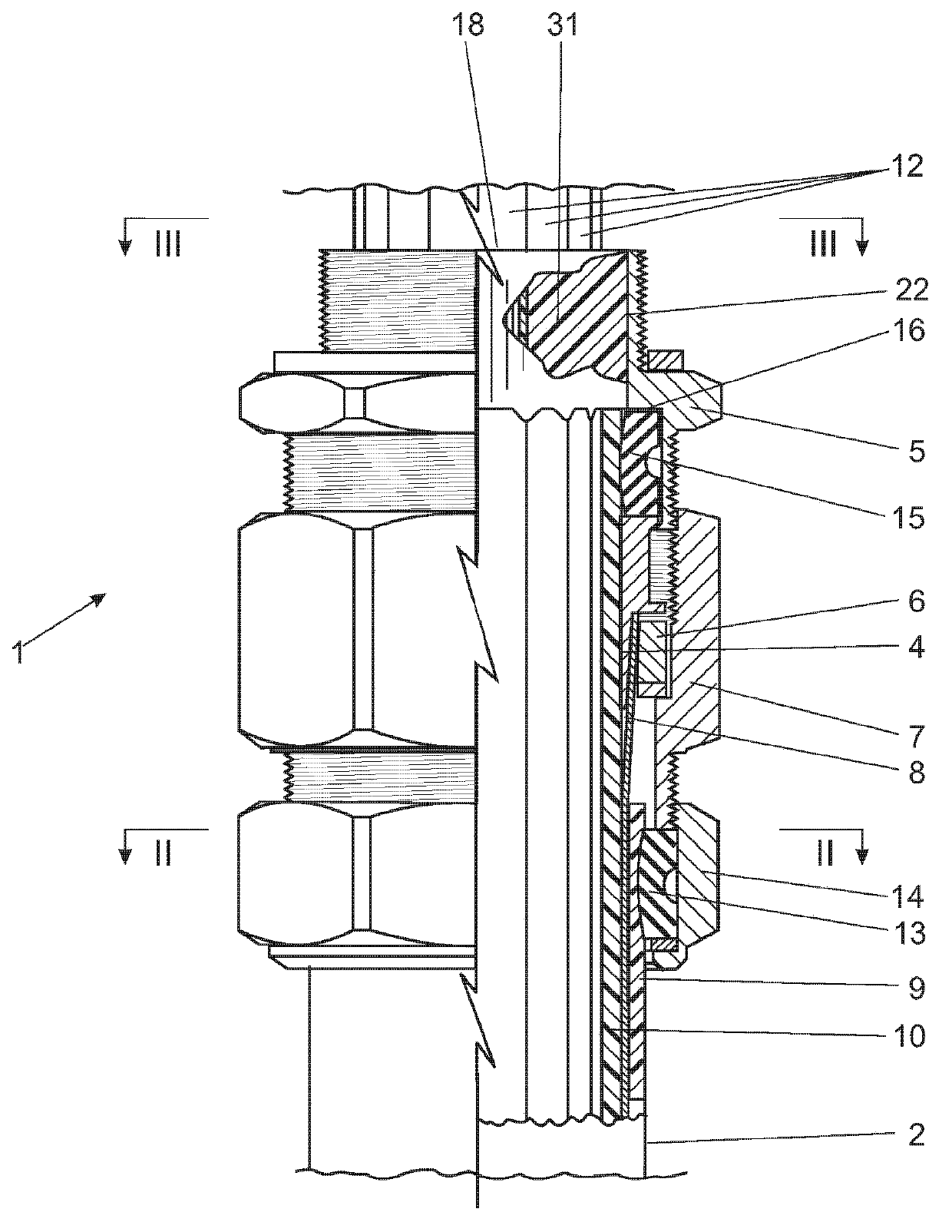

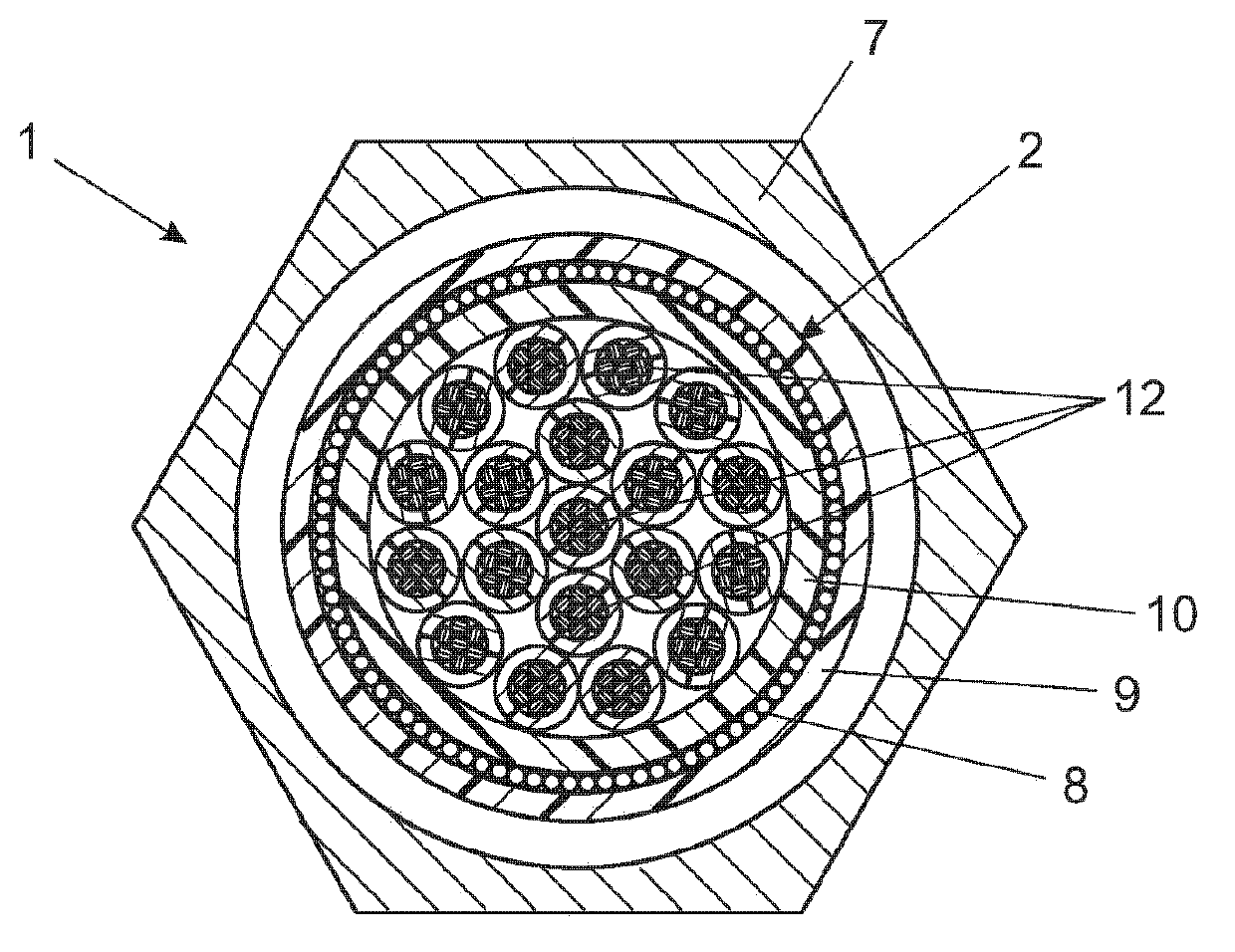

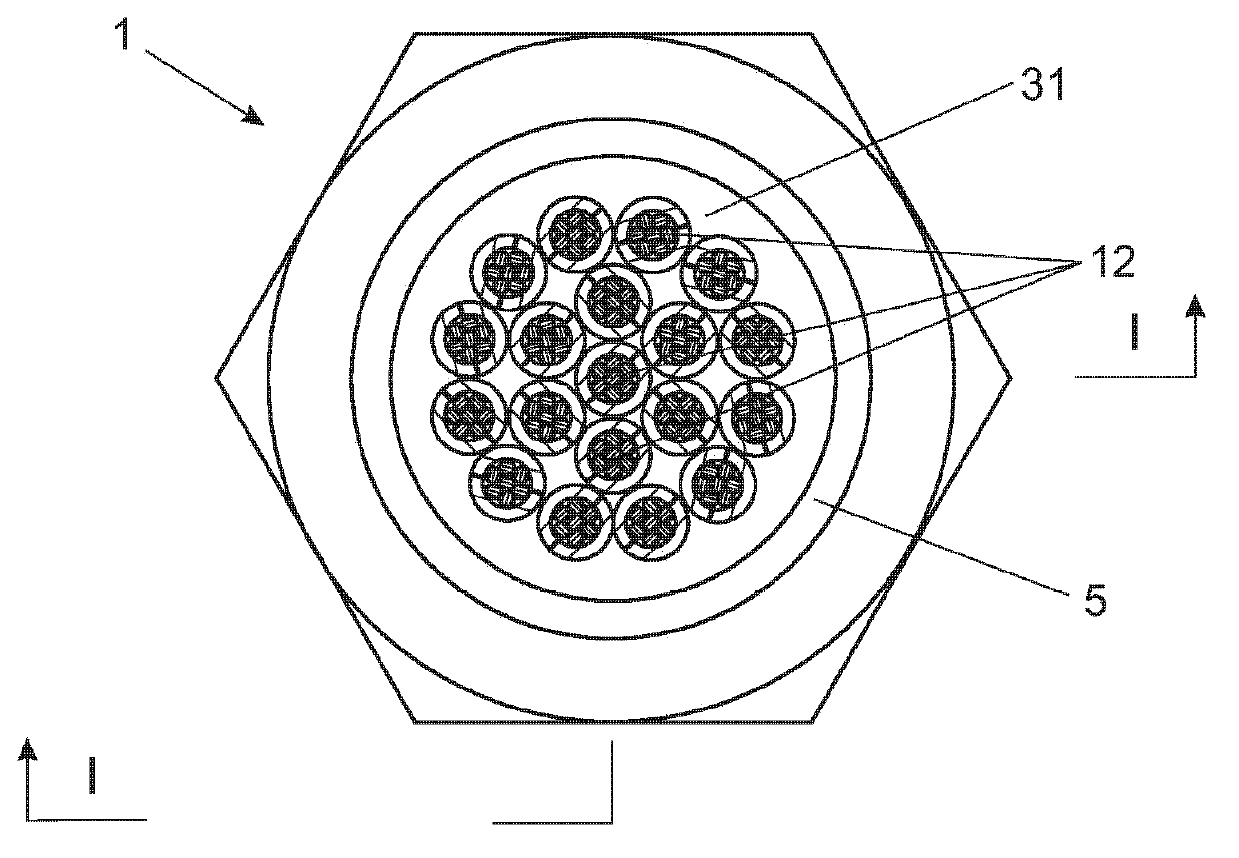

[0028] in the attached Figure 1 to Figure 3 In an application of the invention showing its results, the method of installing a barrier cable gland according to the invention is applied to a cable gland of the type shown in the drawings and described below.

[0029] Such cable glands, generally indicated by the number (1), are made for use on armored or shielded (here referred to as "armored", regardless of their exact nature) cables (2), which have armored clamps Assembly, the armor clamp assembly generally includes an armor clamp cone (4) that preferably remains restrained relative to the inner tubular body (5) and a mating clamp ring that preferably remains restrained relative to the outer tubular body (7) 6). The armor clamp assembly is operable to push the armor clamp cone into a mating clamp ring to securely clamp the cable passing between the outer electrically insulating sheath (9) and the inner electrically insulating sheath (10) Armor Wire (8). This is accomplishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com