Method for modifying a manual transmission

A technology for transmissions and forward gears, applied to vehicle gearboxes, components with teeth, gear transmissions, etc., can solve problems such as recalculation of strength standards, and achieve the effect of small axial structural length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

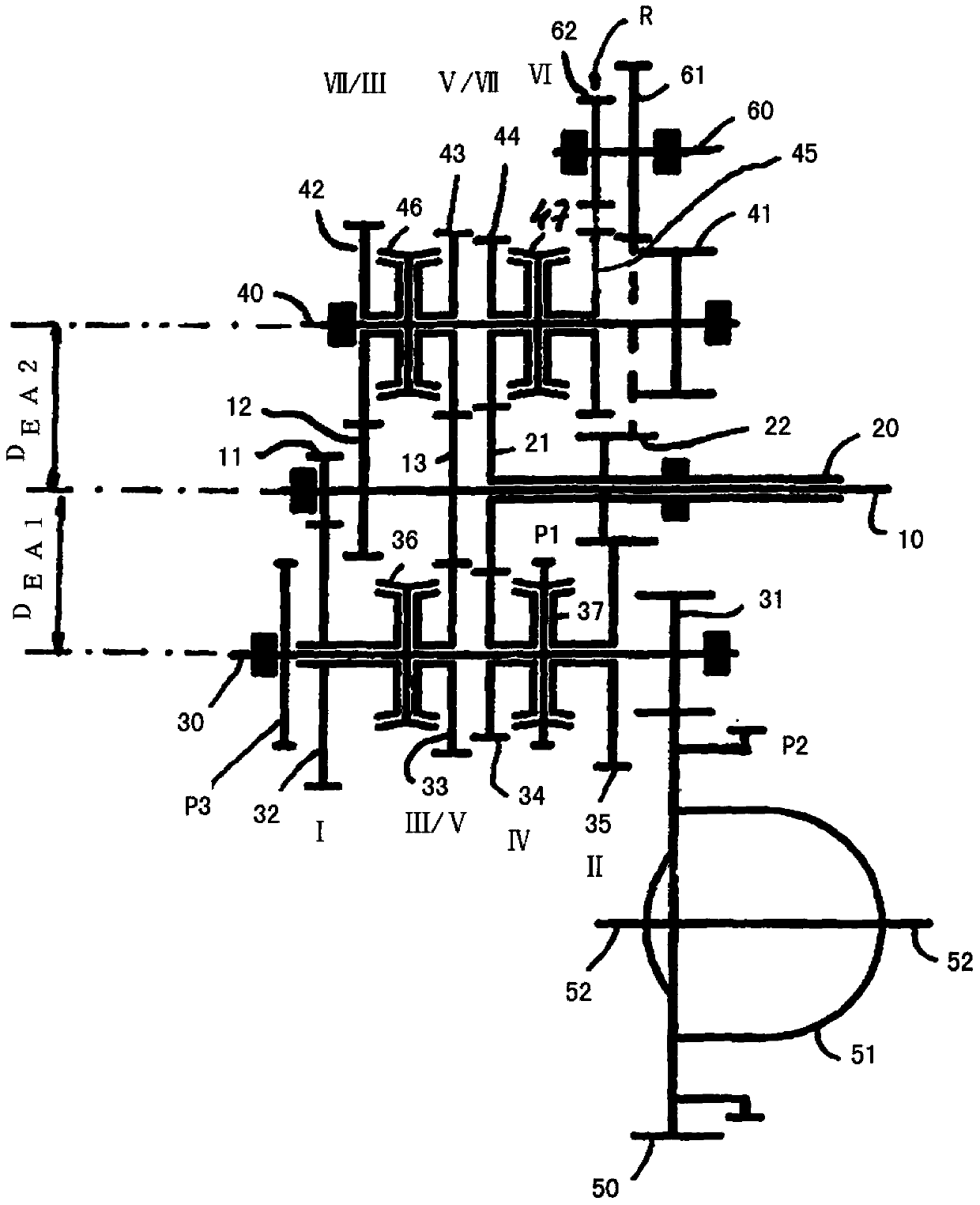

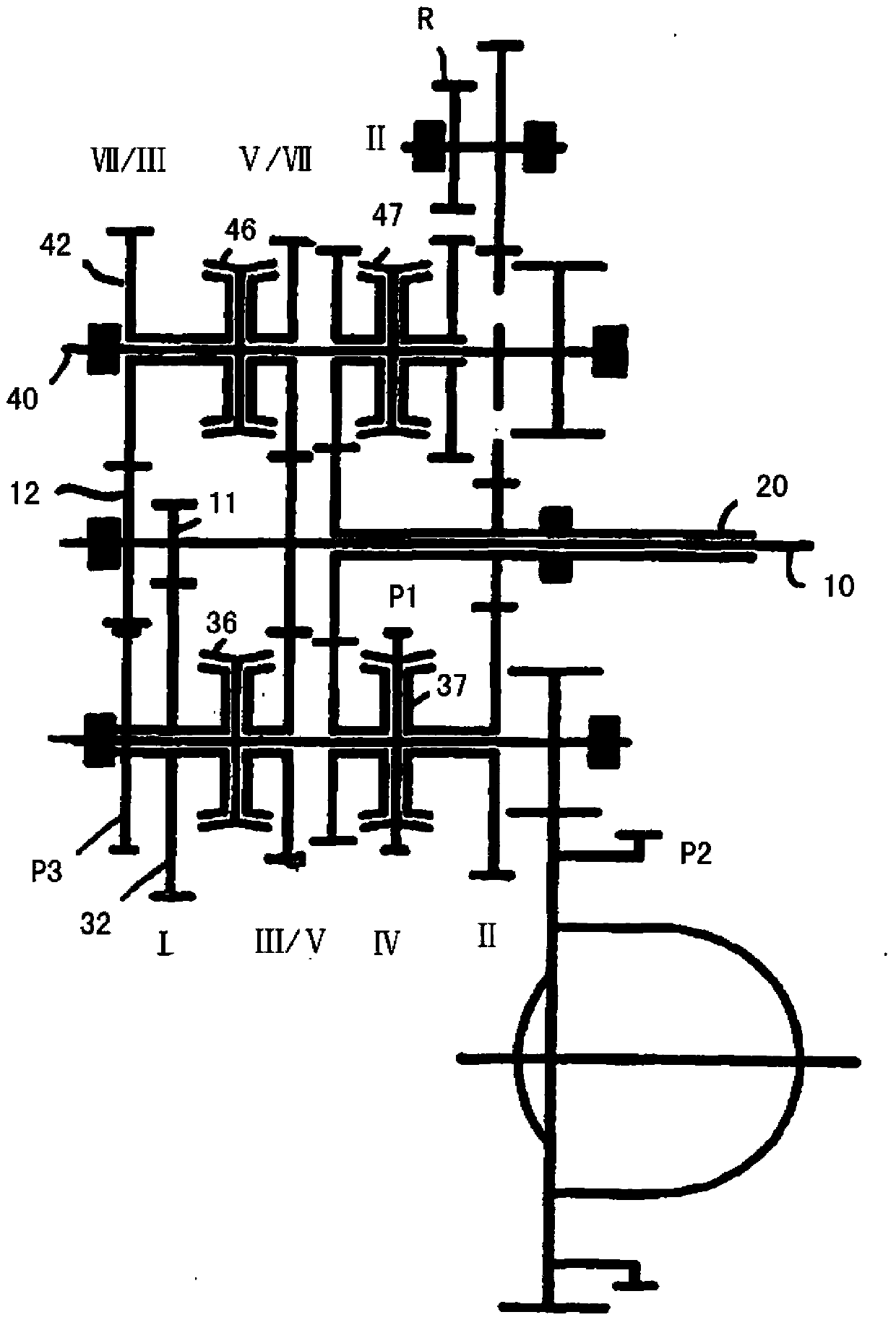

[0027] exist figure 1 , a dual clutch transmission with seven forward gears I to VII and one reverse gear R is schematically shown. First, the following implementation only deals with figure 1 for dual clutch transmissions, but also applies to figure 2 The dual clutch transmission shown in . figure 2 The dual clutch transmission compared to figure 1 The difference between dual clutch transmissions will be discussed later. figure 2 in and figure 1Components and features that are the same are marked with the same reference signs.

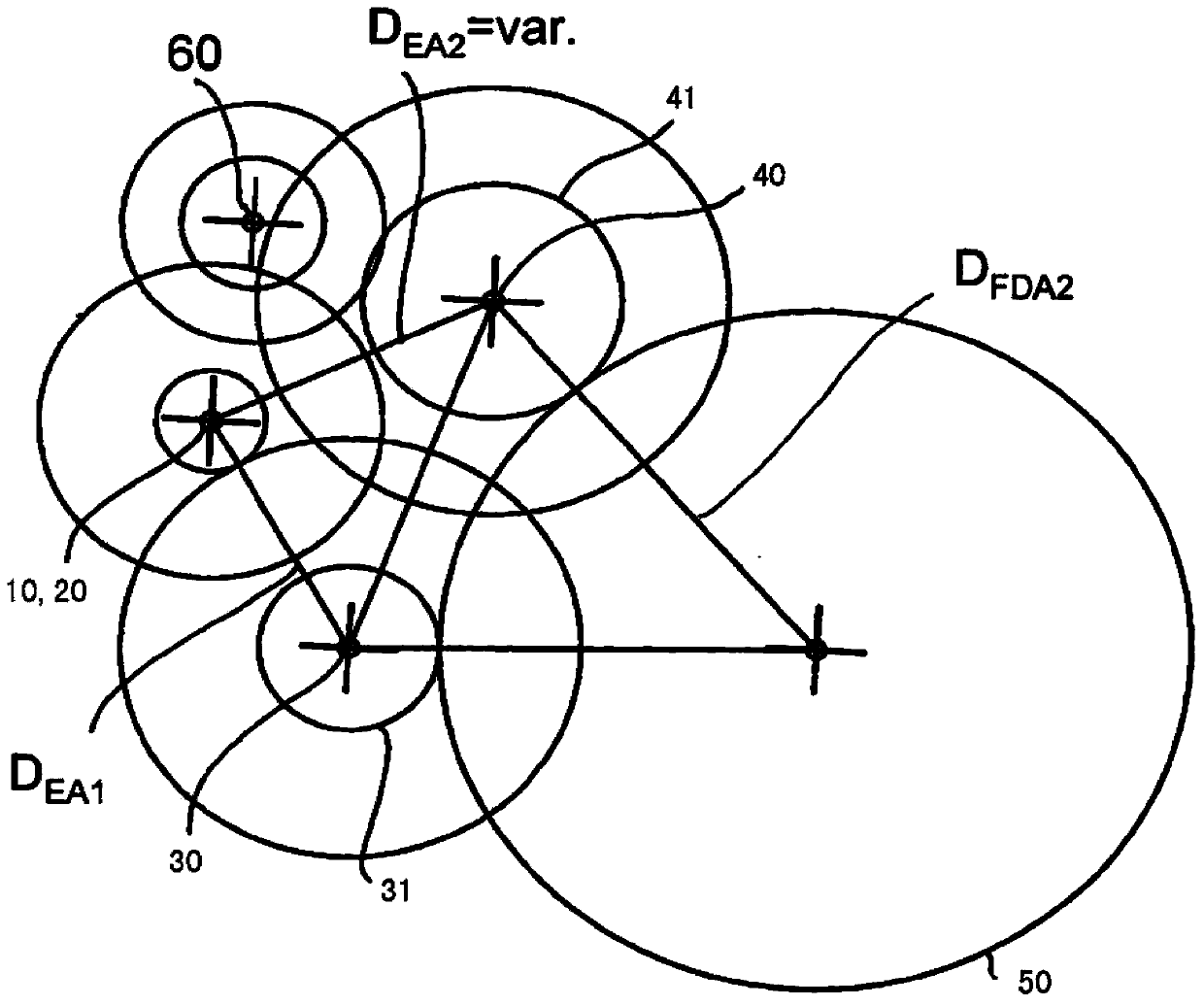

[0028] figure 1 The dual clutch transmission has a first input shaft 10 and a second input shaft 20 . The first input shaft 10 is designed as a solid shaft, while the second input shaft 20 is a hollow shaft which is arranged coaxially with the first input shaft 10 . These input shafts 10, 20 therefore have a common axis of rotation. The first output shaft 30 and the second output shaft 40 are arranged parallel to the first input shaft 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com