A solar film thermal transfer marking machine

A thermal transfer printing and marking machine technology, which is applied to transfer materials, printing, power transmission devices, etc., can solve the problems of inability to place large blocks, high manufacturing costs, and no heat insulation devices, etc., and achieves simple structure and guaranteed equipment, cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

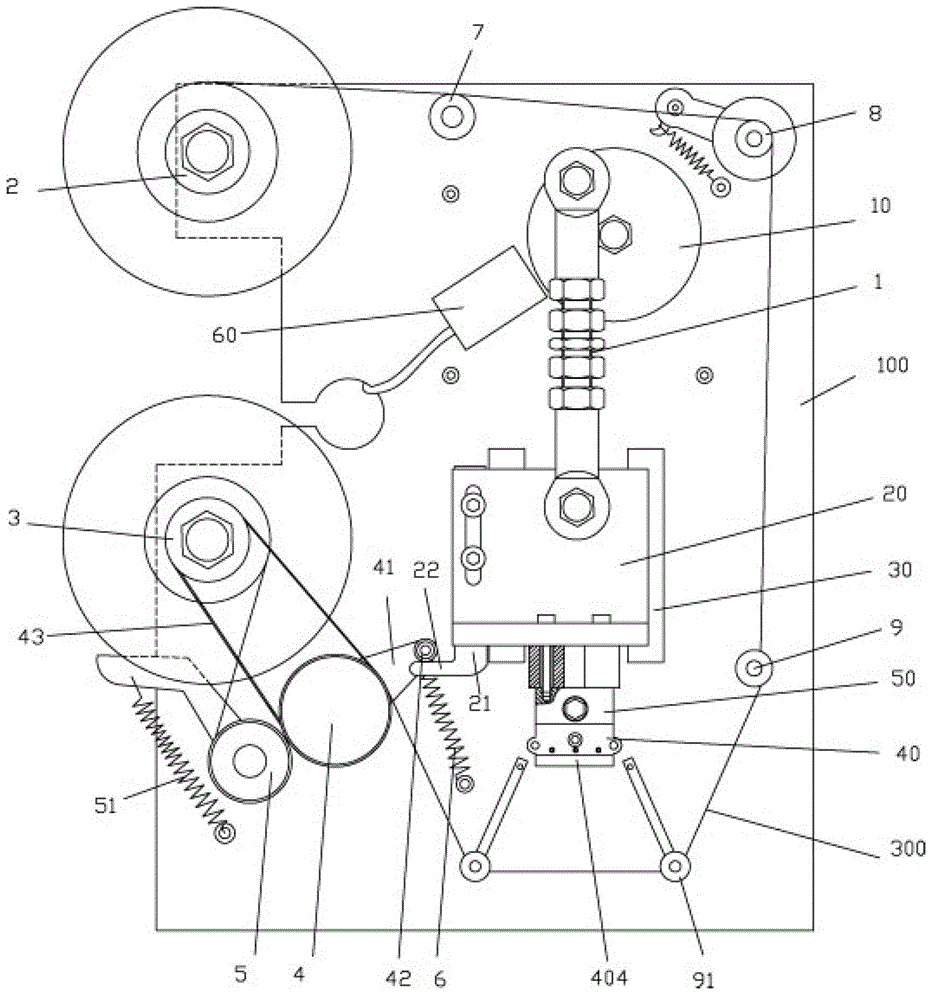

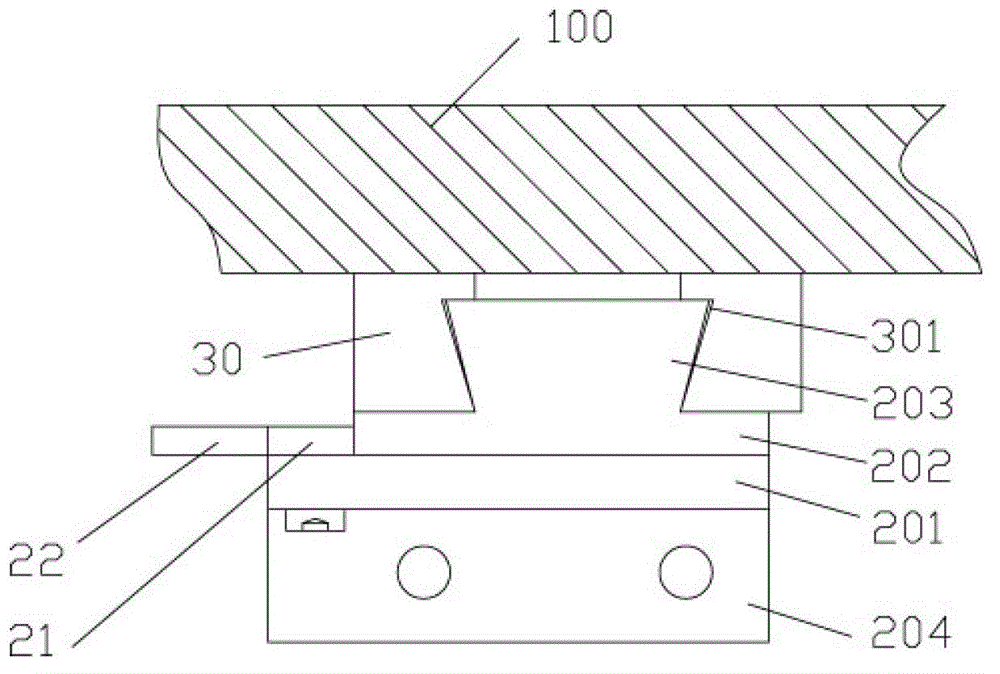

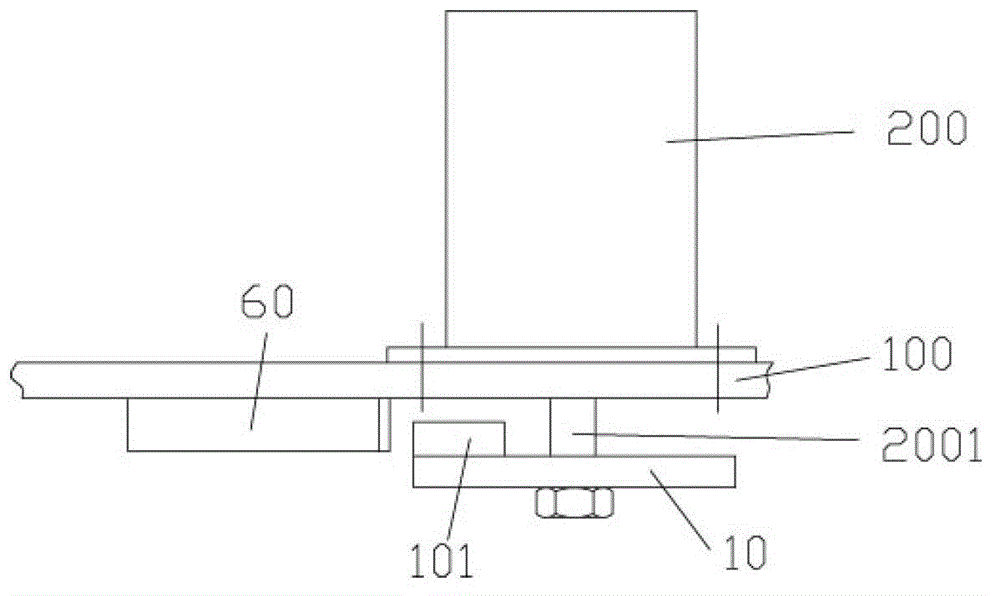

[0025] Examples, see e.g. Figures 1 to 6 As shown, a solar film thermal transfer marking machine includes a support plate 100 and a servo motor 200, the servo motor 200 is fixed on the back of the support plate 100, and the rotating shaft 2001 of the servo motor 200 is inserted into the support plate 100 and extends out On the front of the support plate 100, the top of the rotating shaft 2001 is fixed with a rotating disc 10, the rotating disc 10 is at the middle and upper part of the supporting plate 100, the adjusting rod 1 is below the rotating disc 10, and the upper end of the adjusting rod 1 is hinged on the side of the rotating disc 10. The lower end of the adjusting rod 1 is hinged on the sliding block 20 below the adjusting rod 1, the sliding block 20 is inserted into the sliding rail 30 fixed on the front of the support plate 100, the bottom of the sliding block 20 is fixed with a heating block 50, heating The bottom surface of the block 50 is fixed with a marking de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com