Cooled glass gathering machine

A cooling type, glass technology, applied in the direction of inorganic chemistry, non-metal elements, halogen/halogen acid, etc., can solve the problems of easy deformation, increase, high temperature, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

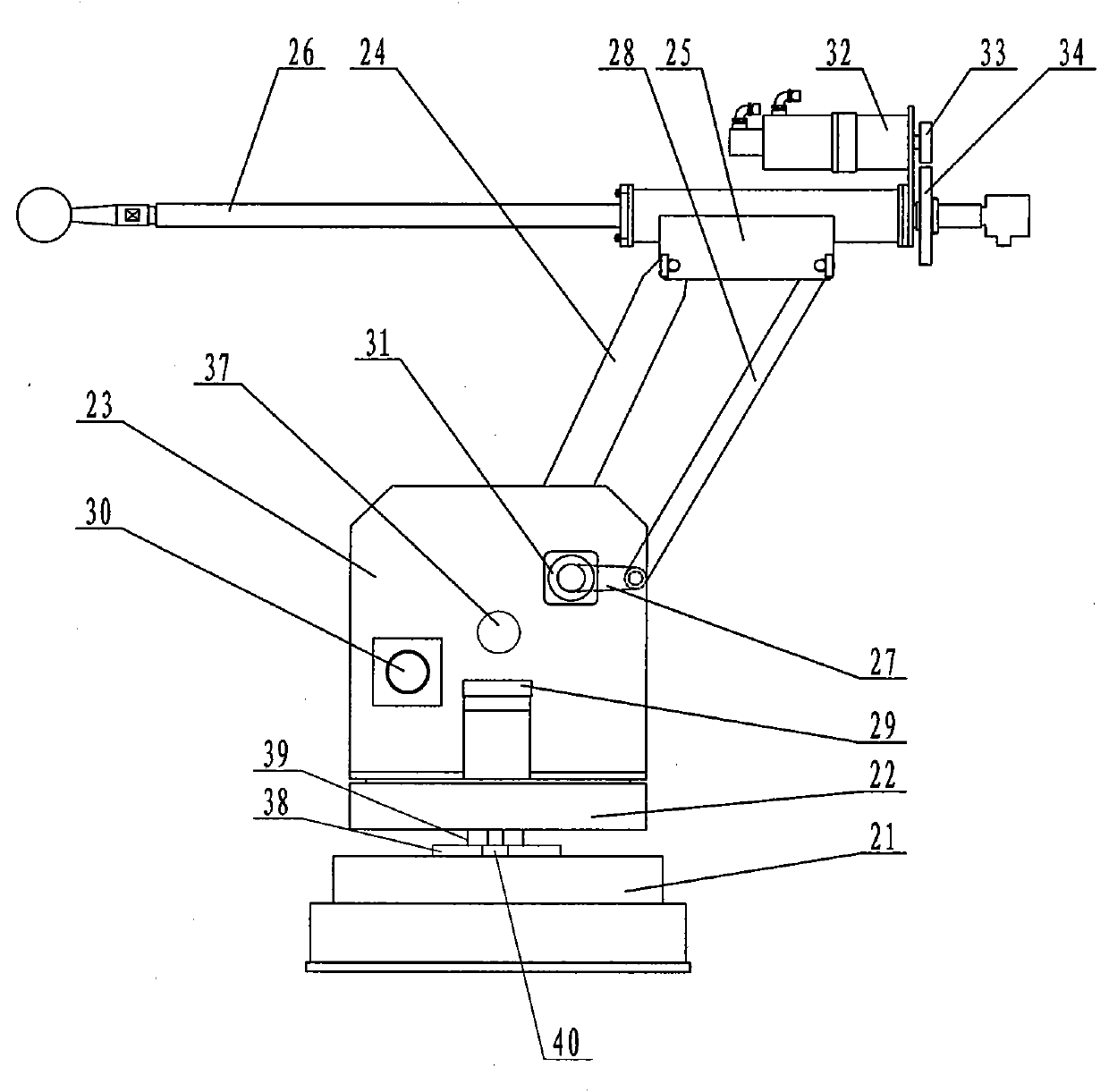

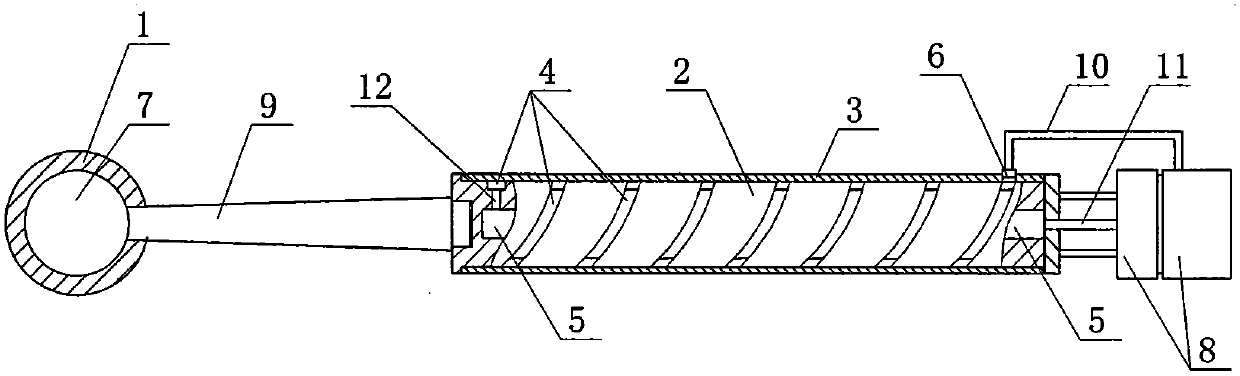

[0011] Such as figure 1 The shown cooling glass picker includes a fixed base 21 and a rotary disc 22 rotatably connected to the fixed base 21 , and the rotation of the rotary disc 22 is driven by a rotary motor 29 mounted on the rotary disc 22 . The connection of the rotary disk 22 and the way the rotary motor 29 drives it to rotate can adopt the following structure: the ring gear 38 and the support shaft 39 located at the center of the ring gear are fixedly installed on the fixed seat 21, and the rotary disk 22 is rotatably connected to the support shaft. Above, the gear 40 meshed with the ring gear 38 is housed on the rotary motor 29, and the rotary motor 29 drives the gear to rotate to realize the rolling of the gear on the ring gear, thereby realizing the rotation of the rotary disc 22. A frame 23 is fixedly connected on the rotary disk 22, and a rocker motor 30 and a pull rod motor 31 are mounted on the frame 23 and are connected with a rotatable rocker shaft 37; the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com