Patents

Literature

36results about How to "Not prone to thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

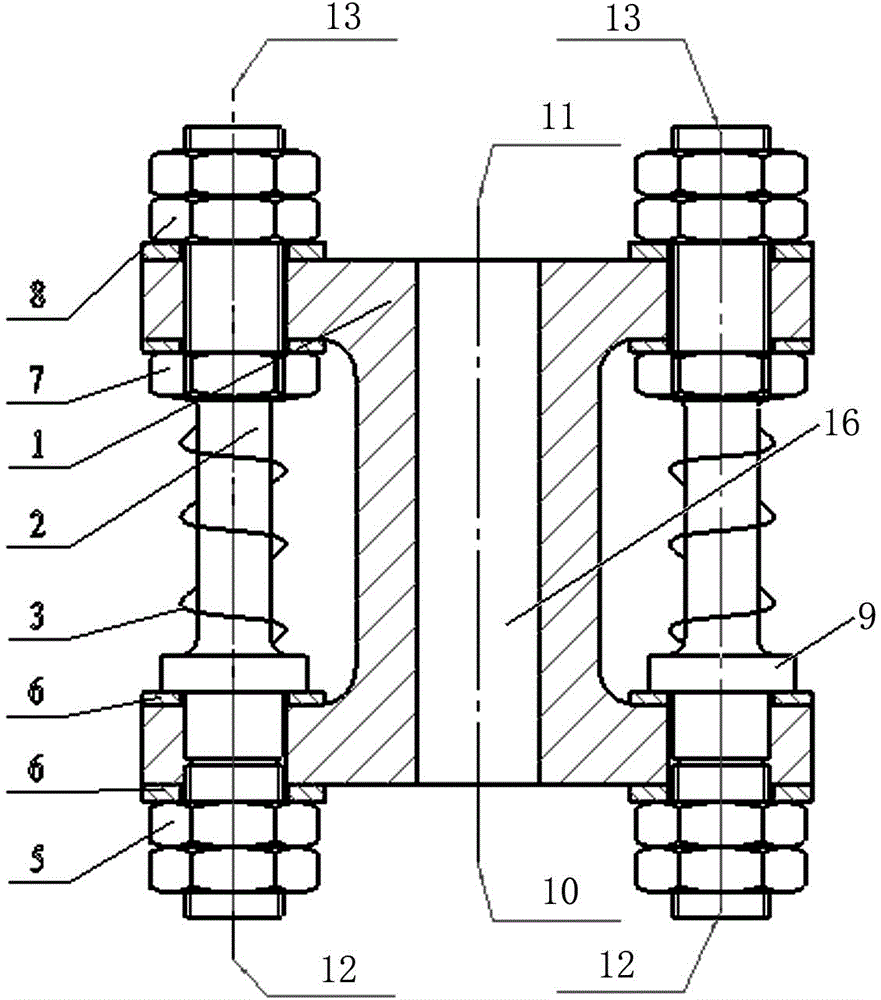

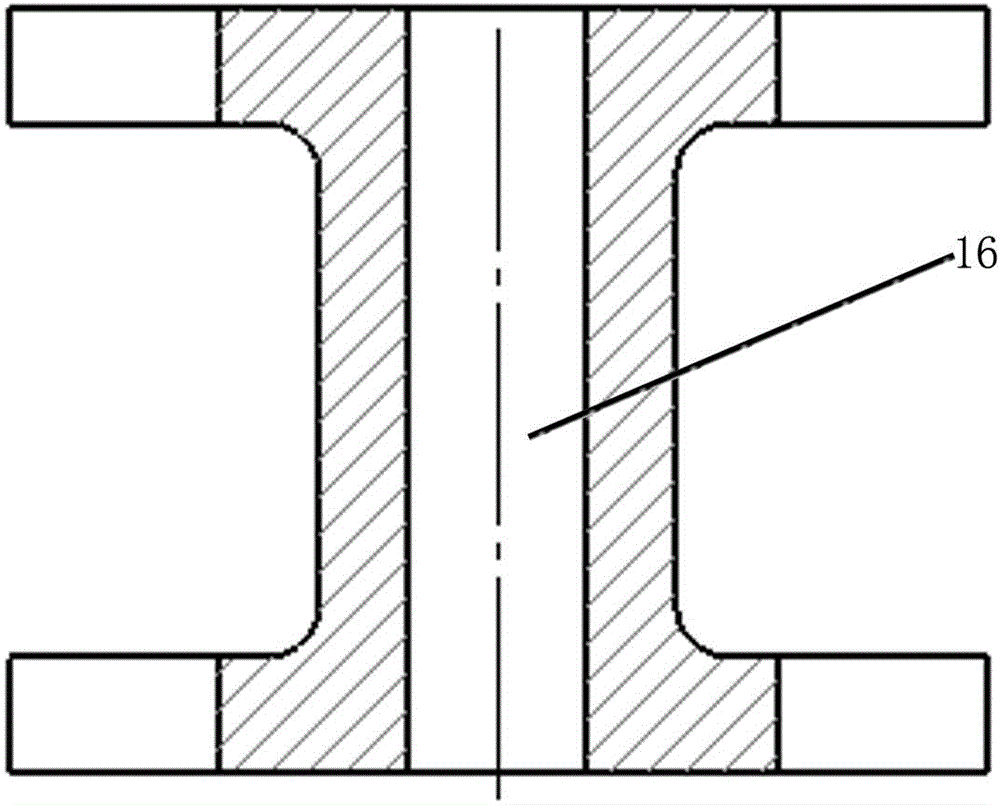

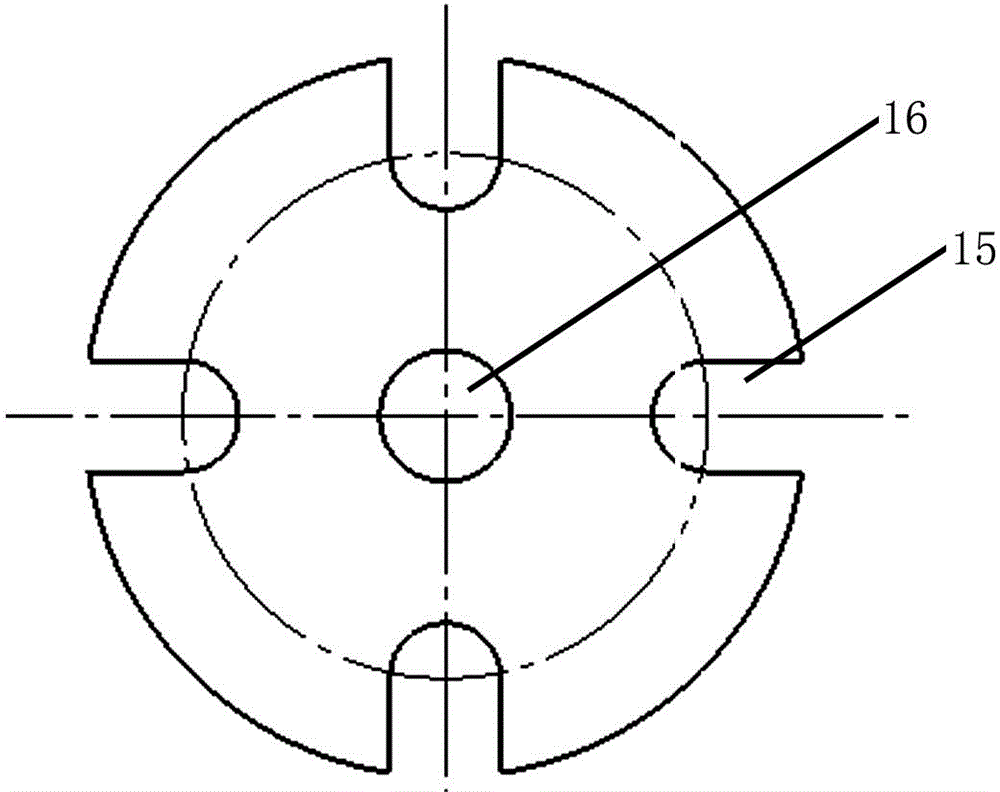

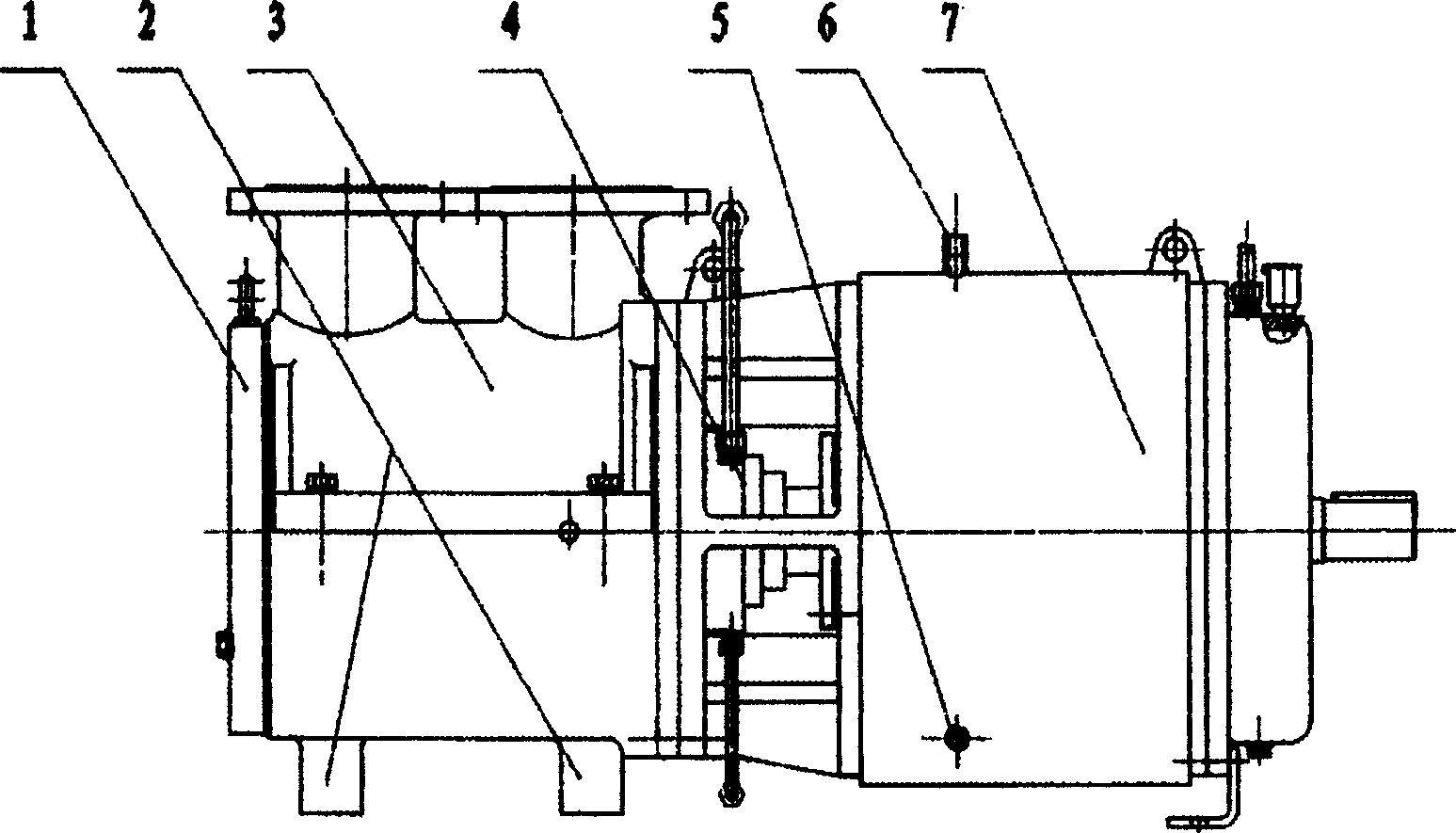

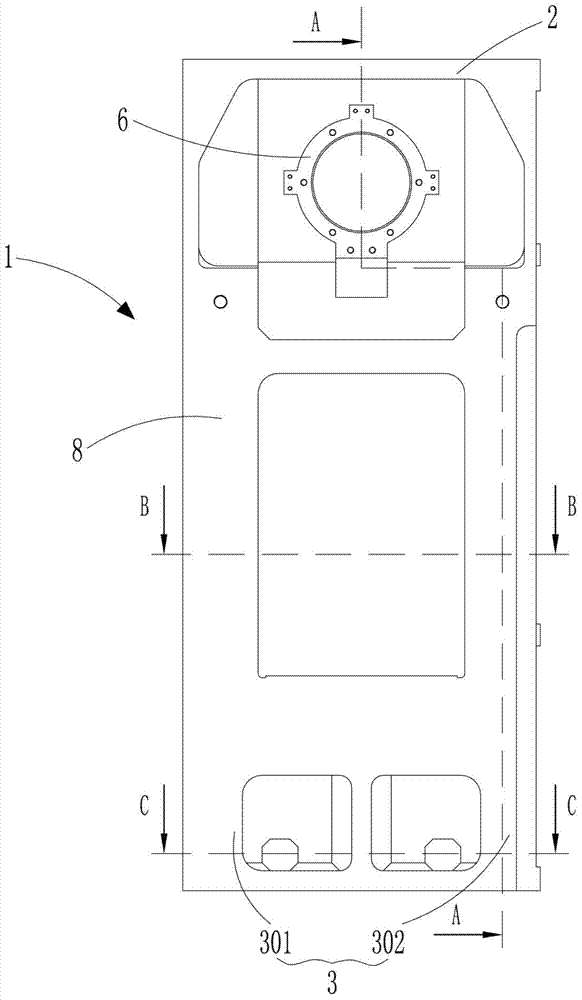

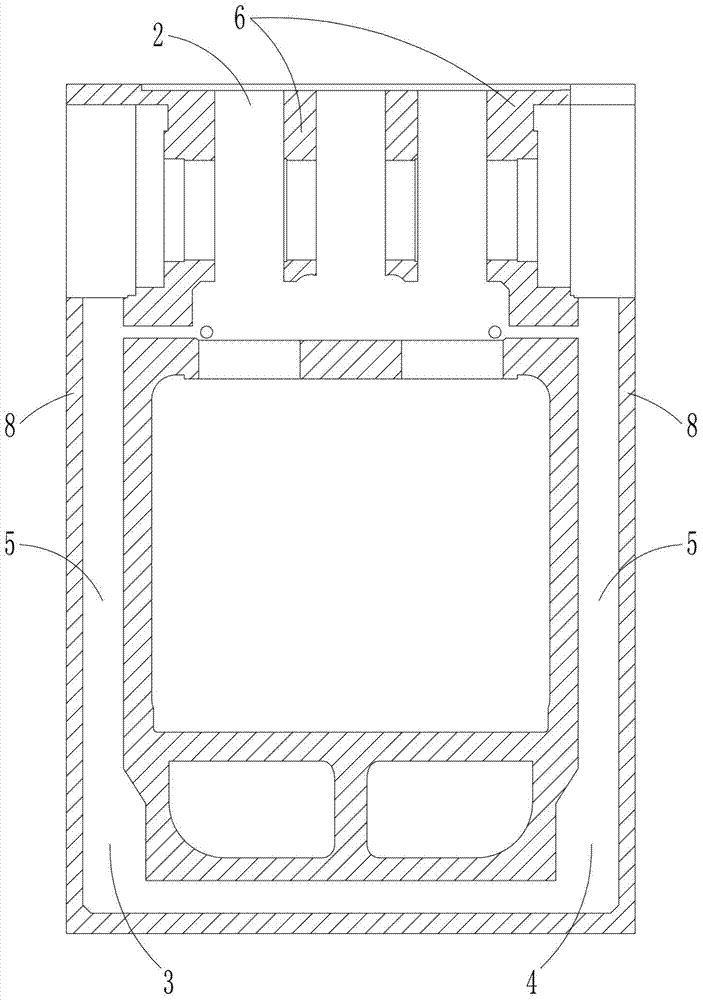

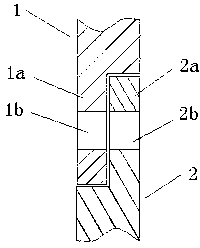

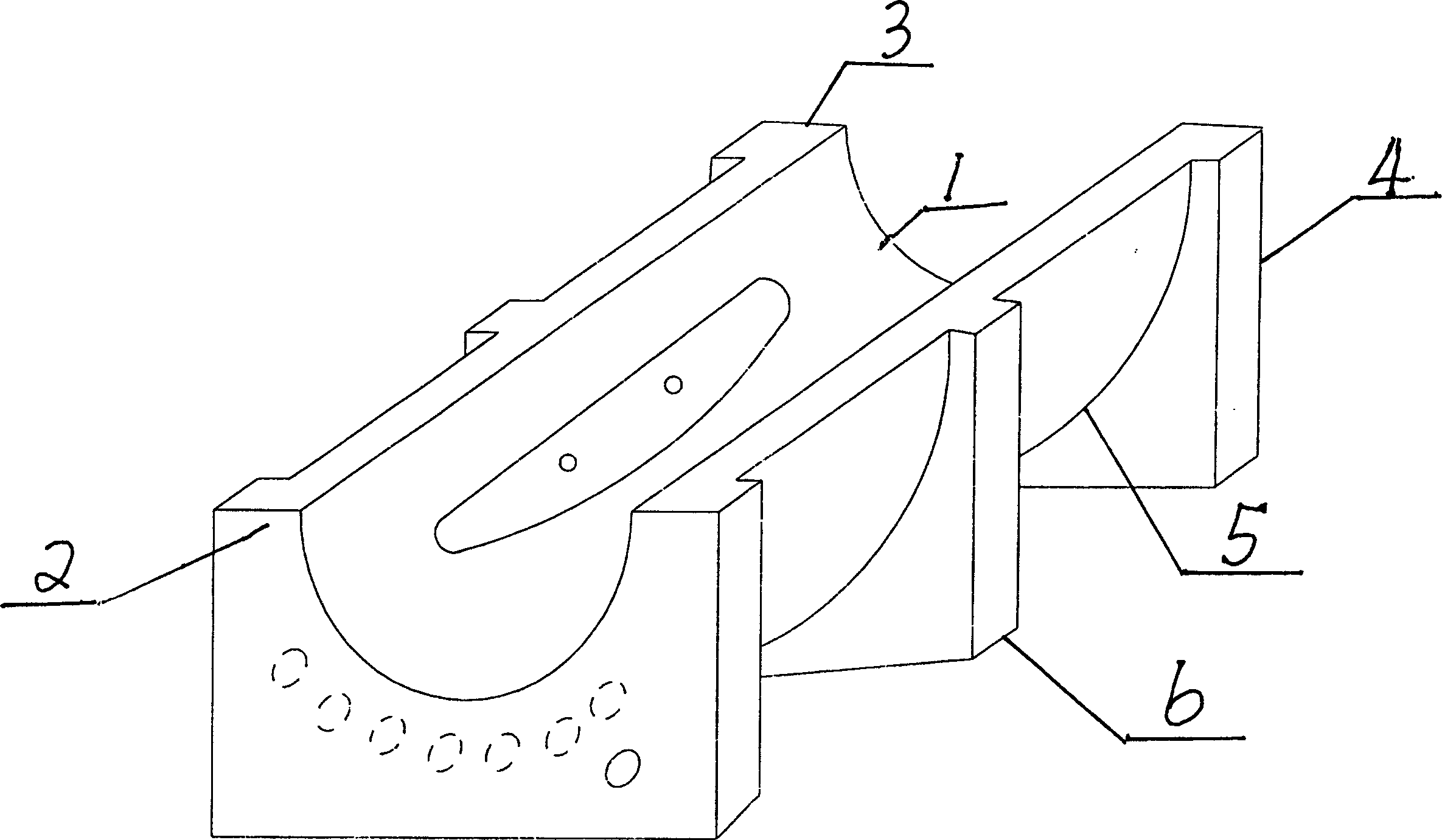

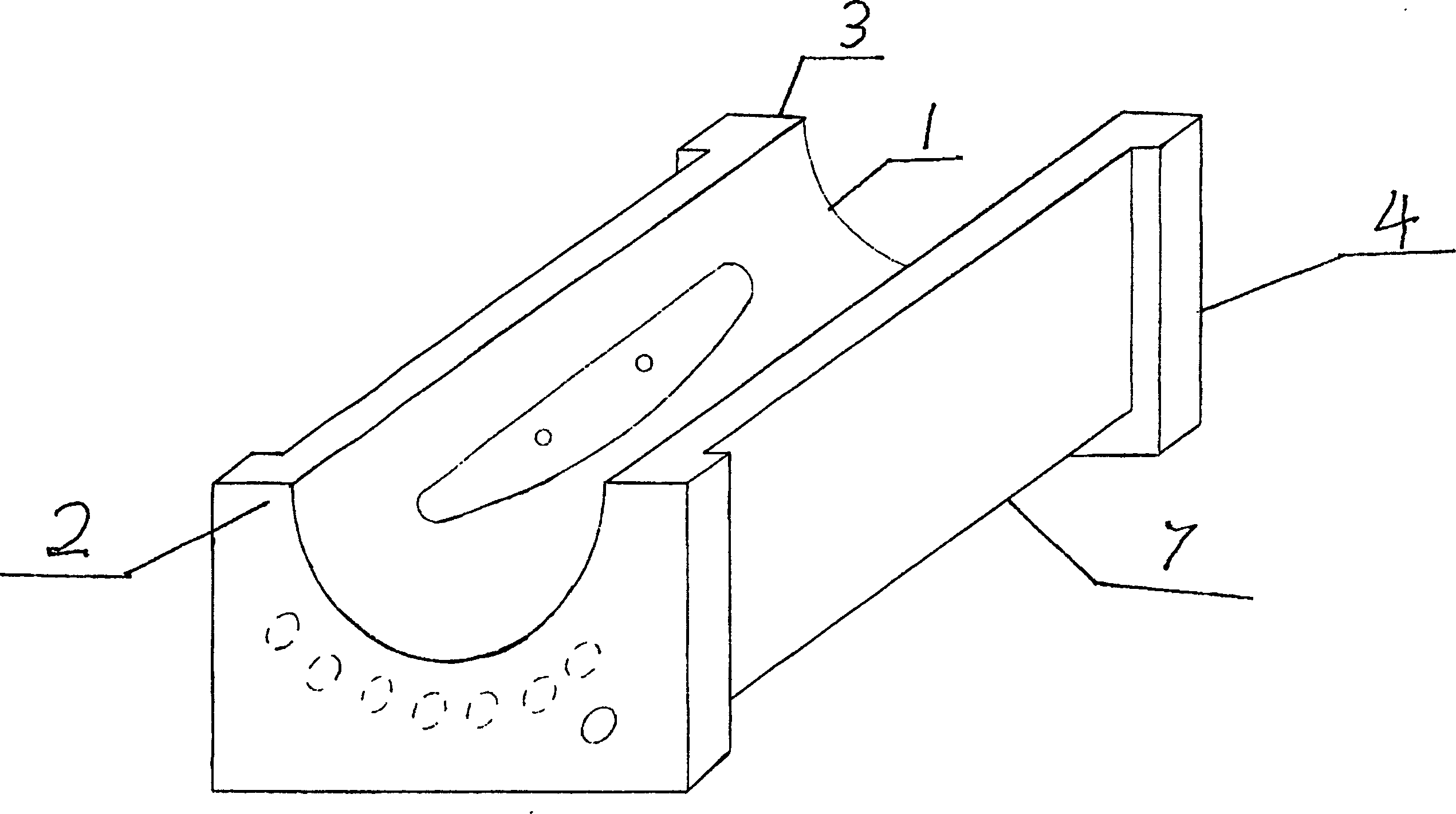

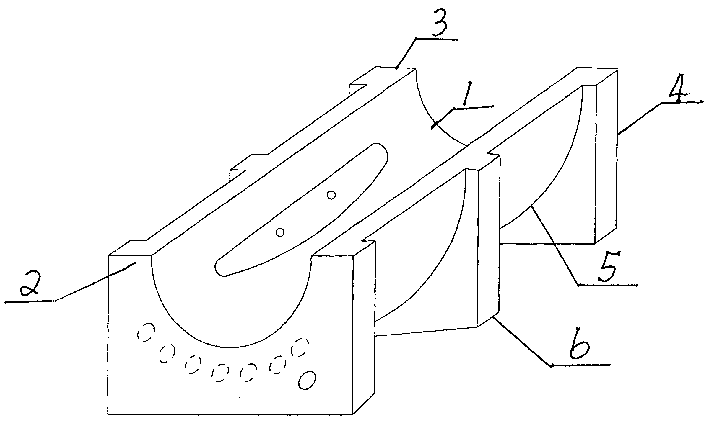

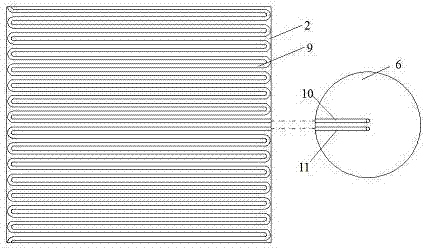

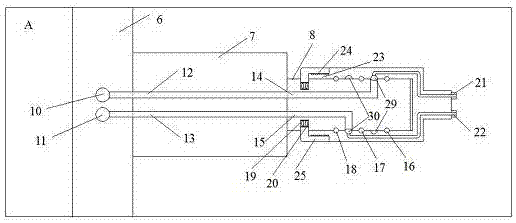

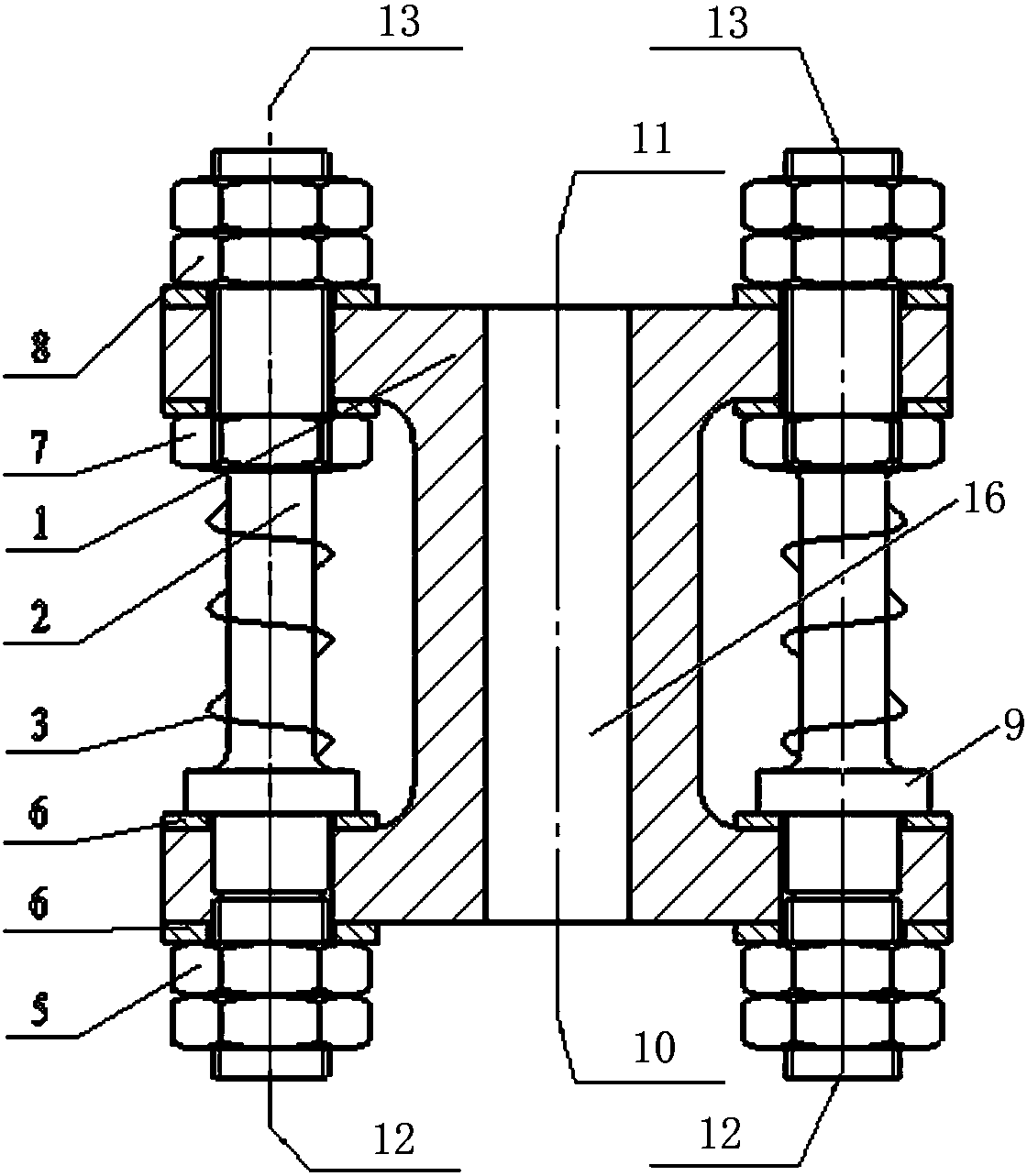

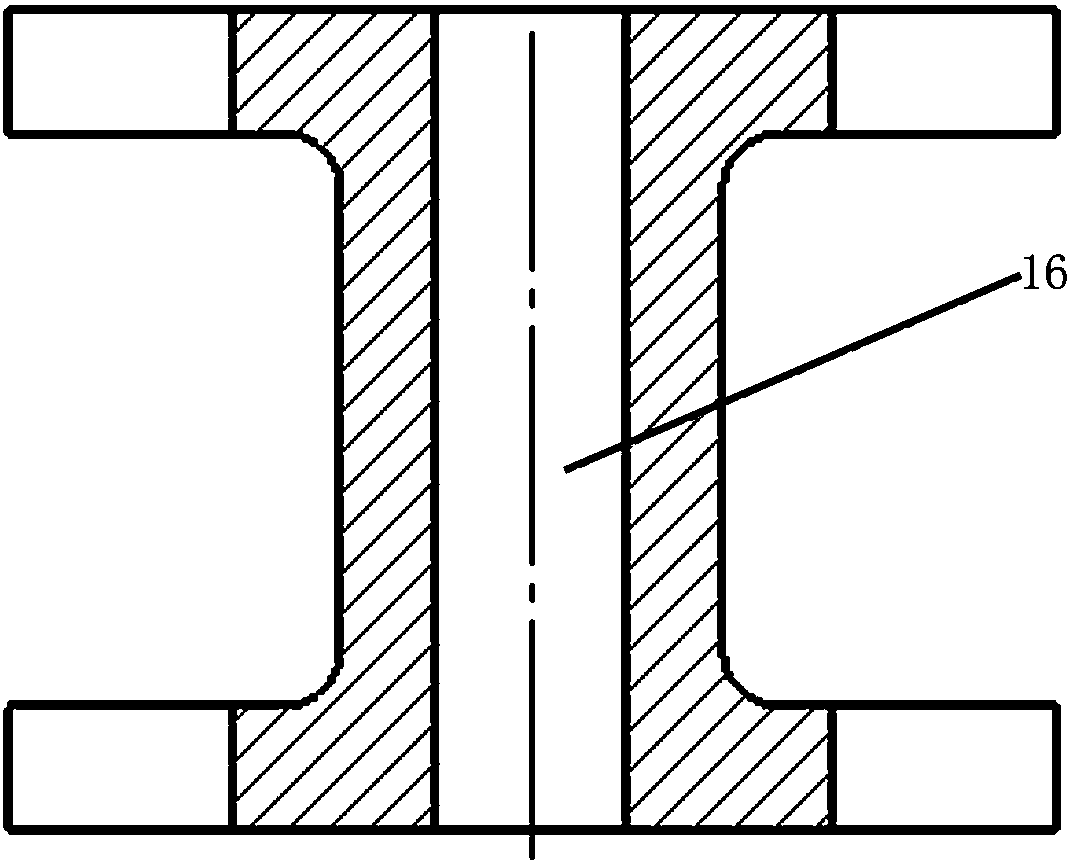

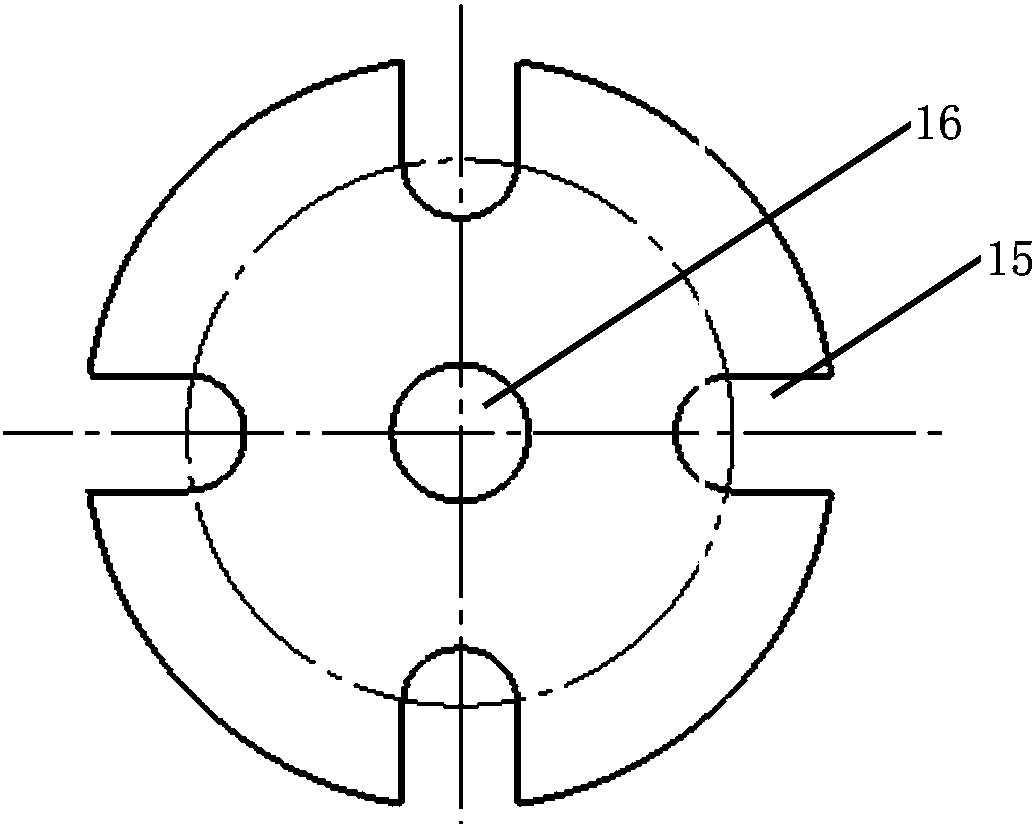

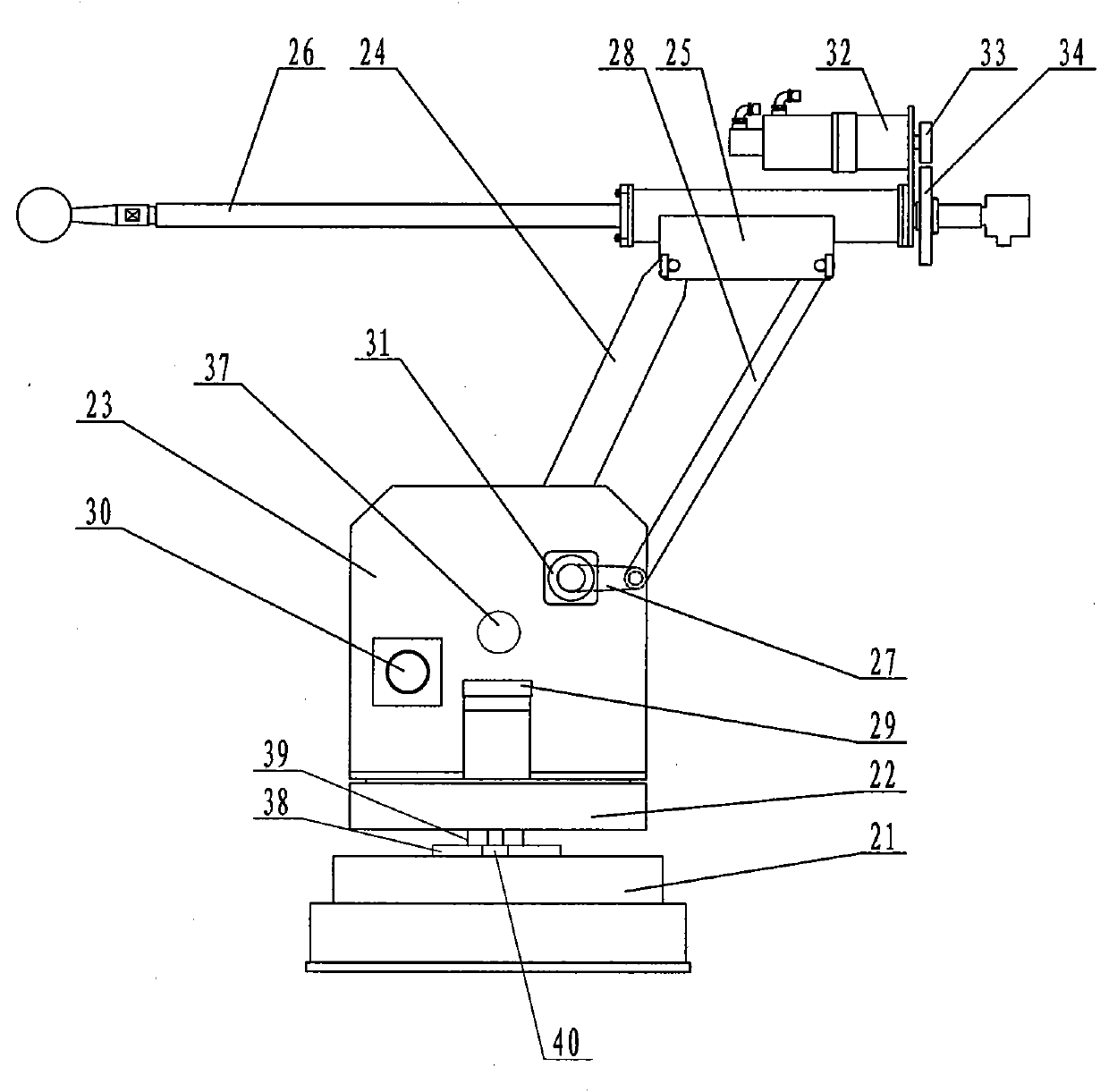

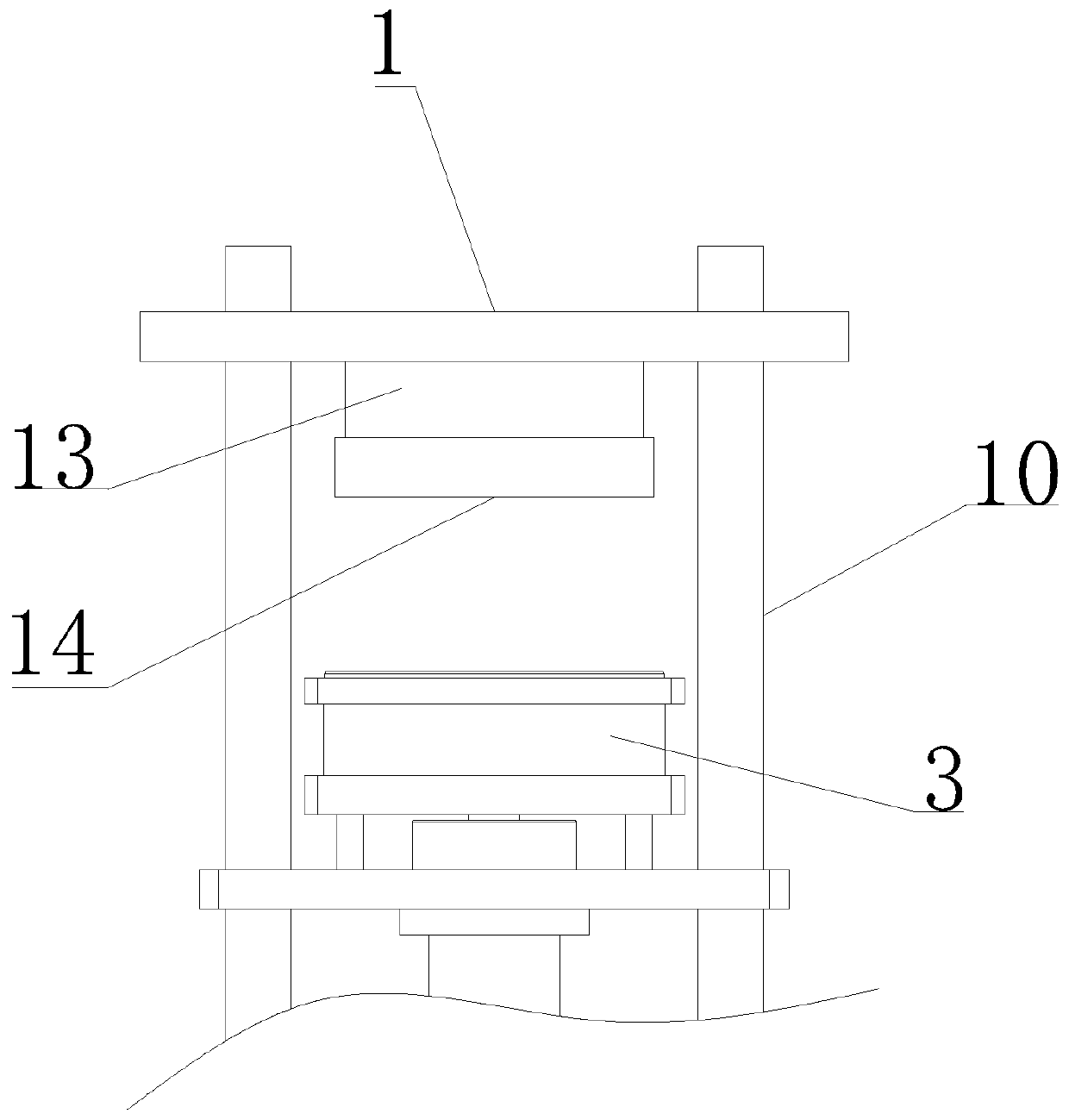

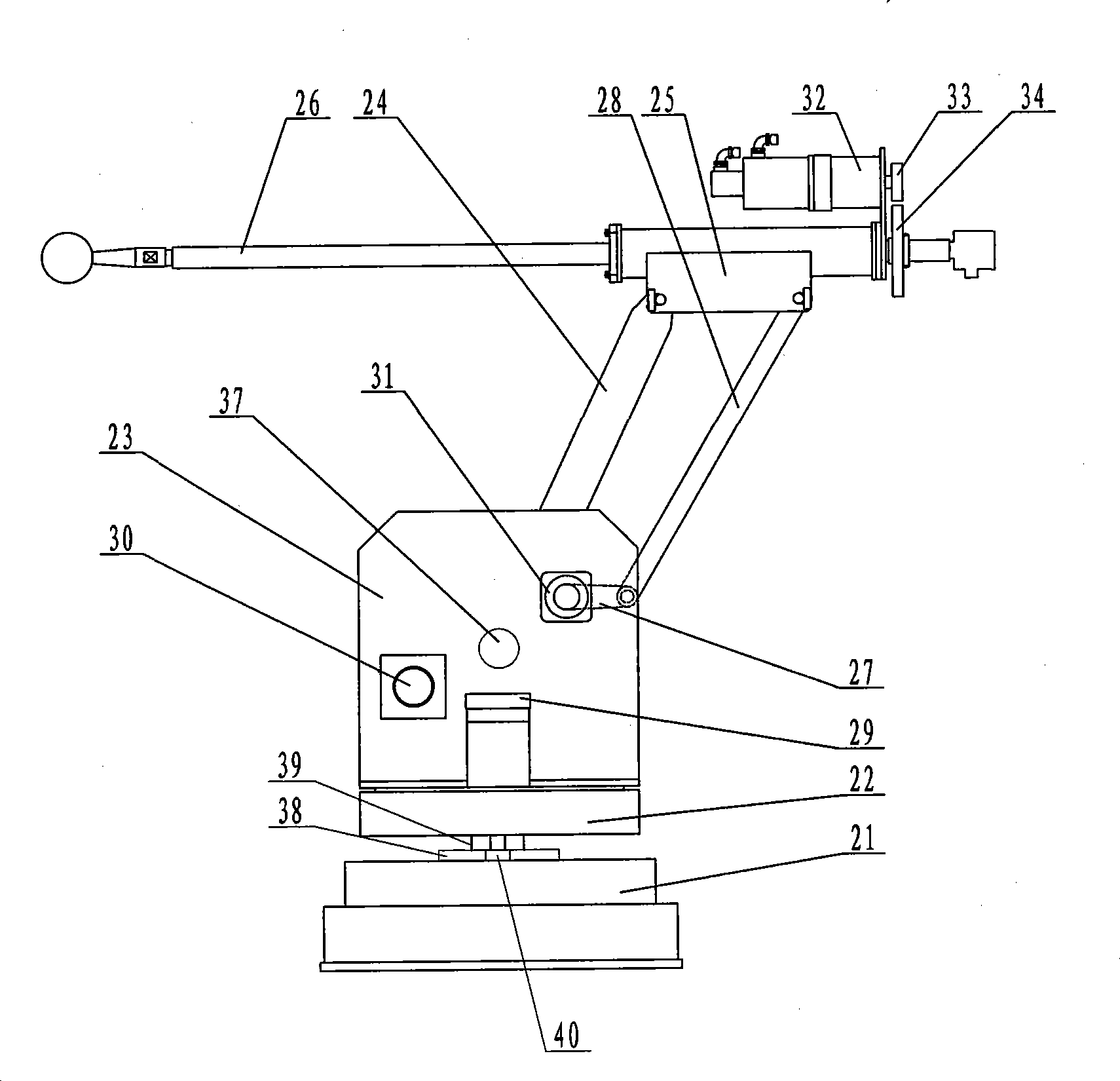

Thermal fatigue testing machine

The invention provides a thermal fatigue testing machine which is characterized by comprising a support and a thermal fatigue testing specimen, wherein the support is of a support pillar structure with an upper flange and a lower flange; the center of the support is provided with a support cooling water channel; the upper part of the thermal fatigue testing specimen is clamped at the upper flange of the support, while the lower part of the thermal fatigue testing specimen is clamped at the lower flange of the support; and the outer wall of the thermal fatigue testing specimen is wound with an induction heating coil. The thermal fatigue testing machine is reasonable in structure, scientific in operation, remarkable in effects and suitable to popularization and application in the field of thermal fatigue testing.

Owner:SHENYANG POLYTECHNIC UNIV

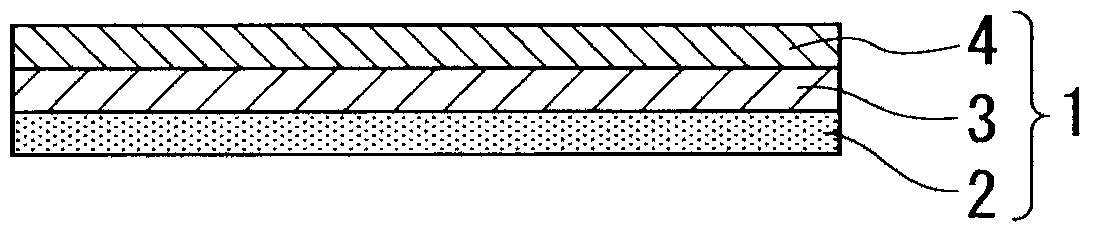

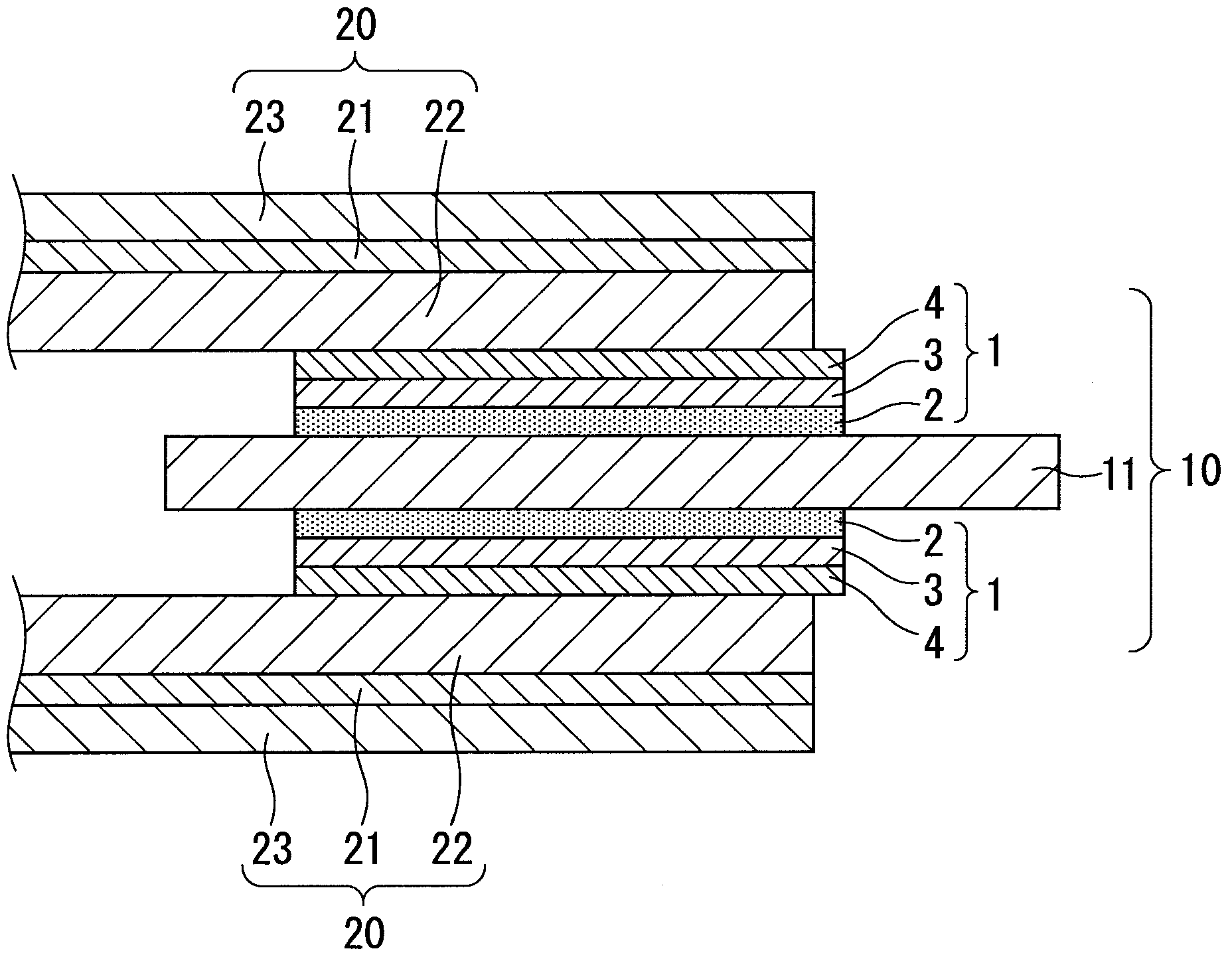

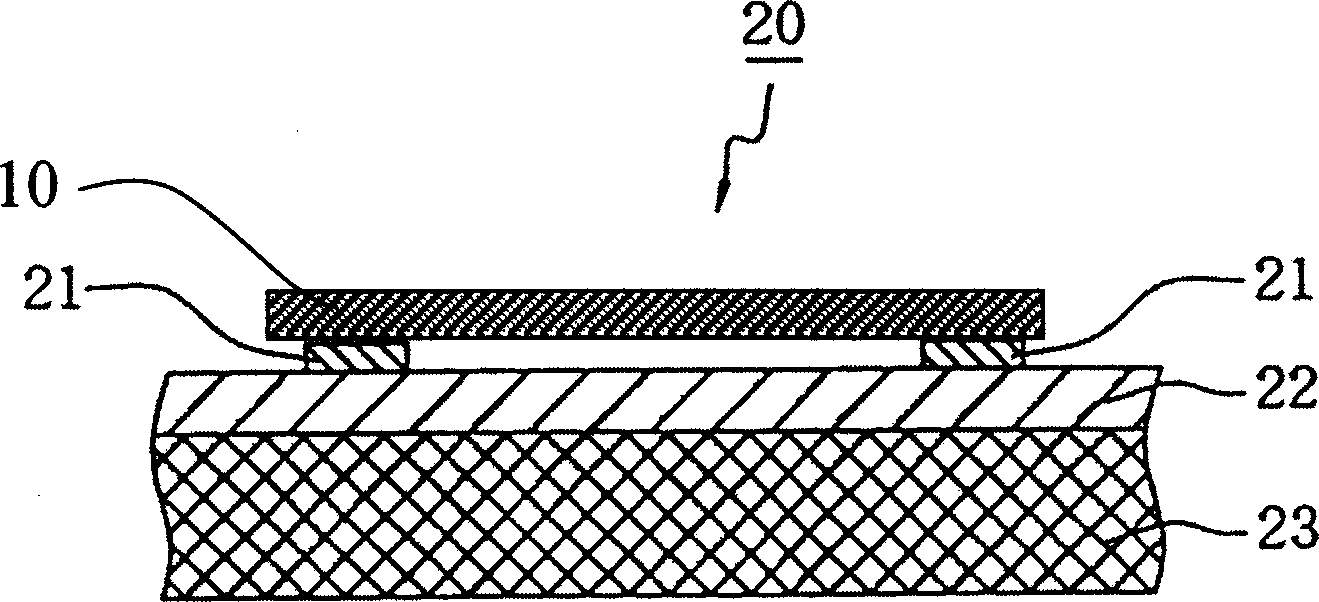

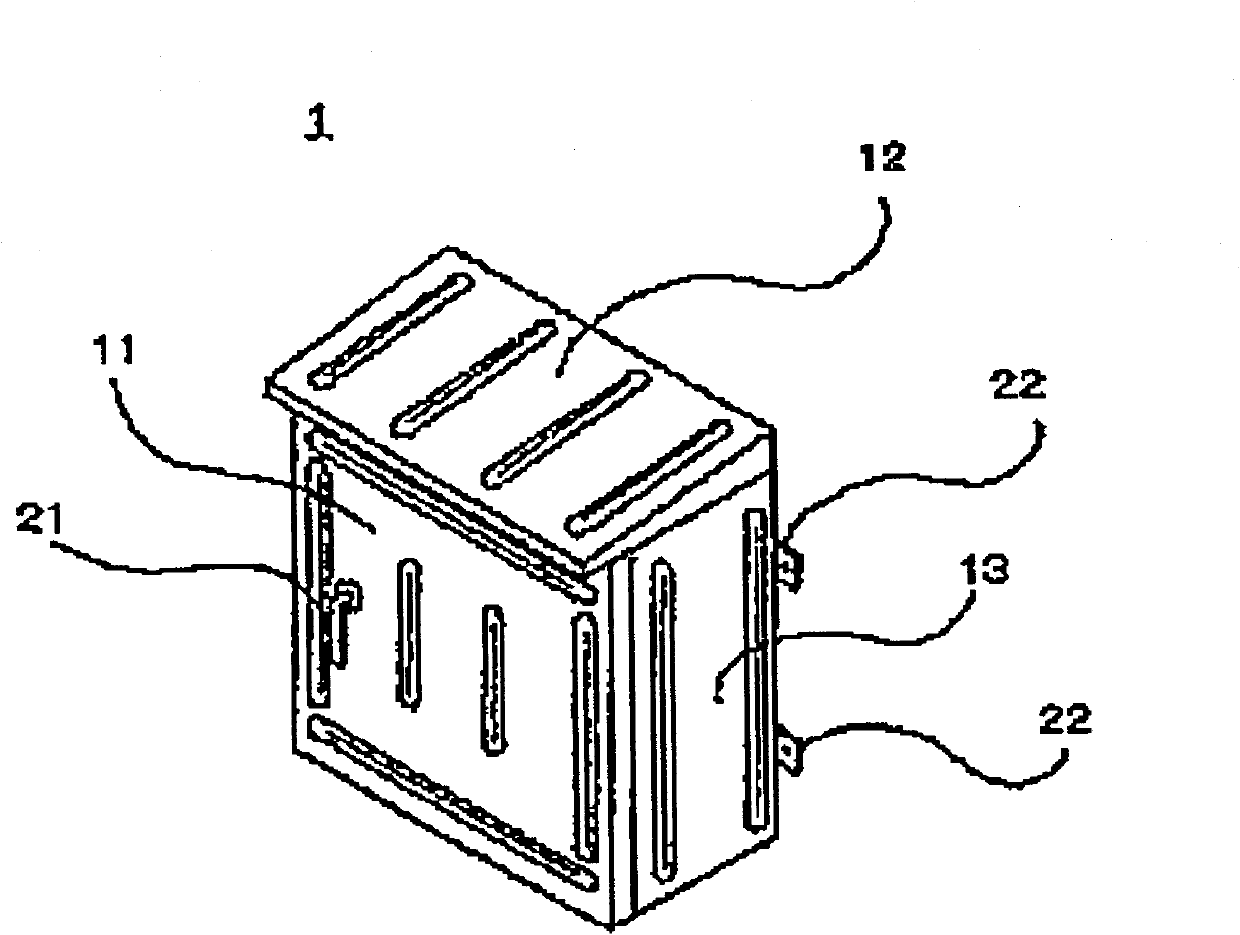

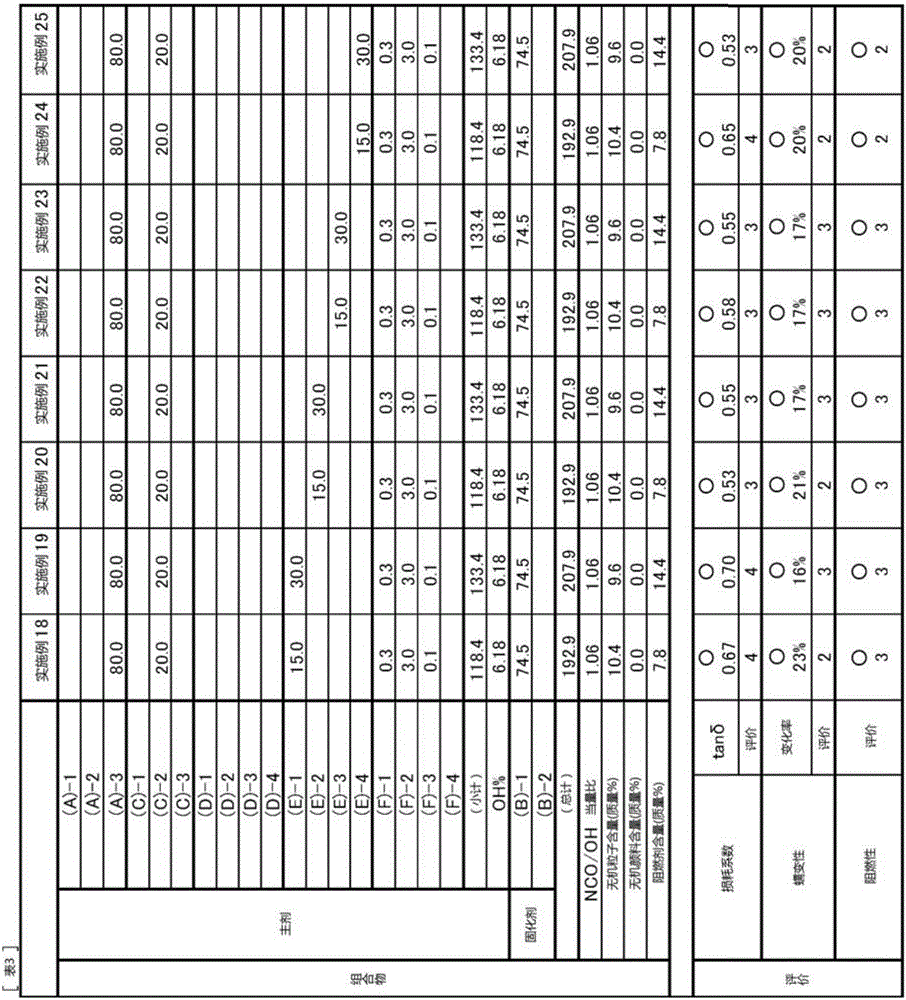

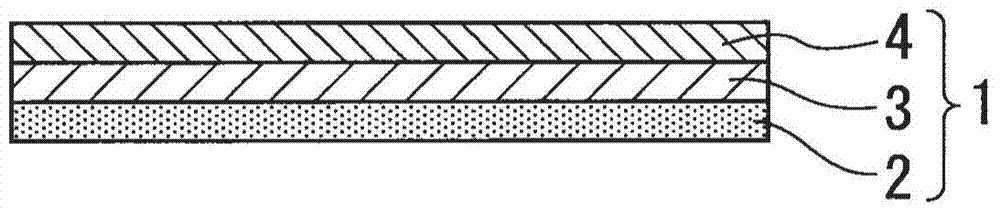

Process for producing sealing film, and sealing film

ActiveCN103222084ANot prone to short circuitImprove joint strengthSynthetic resin layered productsDouble layer capacitorsMolten stateChemical Linkage

A process for producing a sealing film (1) to be interposed between each electrode (11), as a power-generating element, that has been introduced into a bag (20) and the edge of the bag (20), the process comprising: a melt kneading step in which both an acid-modified polyolefin resin A to which a carboxylic acid has been grafted and a resin B having functional groups capable of reacting with the carboxy groups of the resin A are melted and kneaded together to thereby chemically bond the carboxy groups of the resin A to the functional groups of the resin B and convert the resins into a resin C; a heat-resistant-layer formation step in which the resin C is formed into a layer to form a heat-resistant layer (3); an adhesive-layer formation step in which a carboxylic-acid-modified polyolefin resin D is formed into a layer to form an electrode adhesion layer (2) which adheres to electrodes; and a laminating step in which the heat-resistant layer (3) and the electrode adhesion layer (2) are directly laminated to each other when the resin C and / or the resin D is in a molten state.

Owner:FUJIMORI KOGYO CO LTD

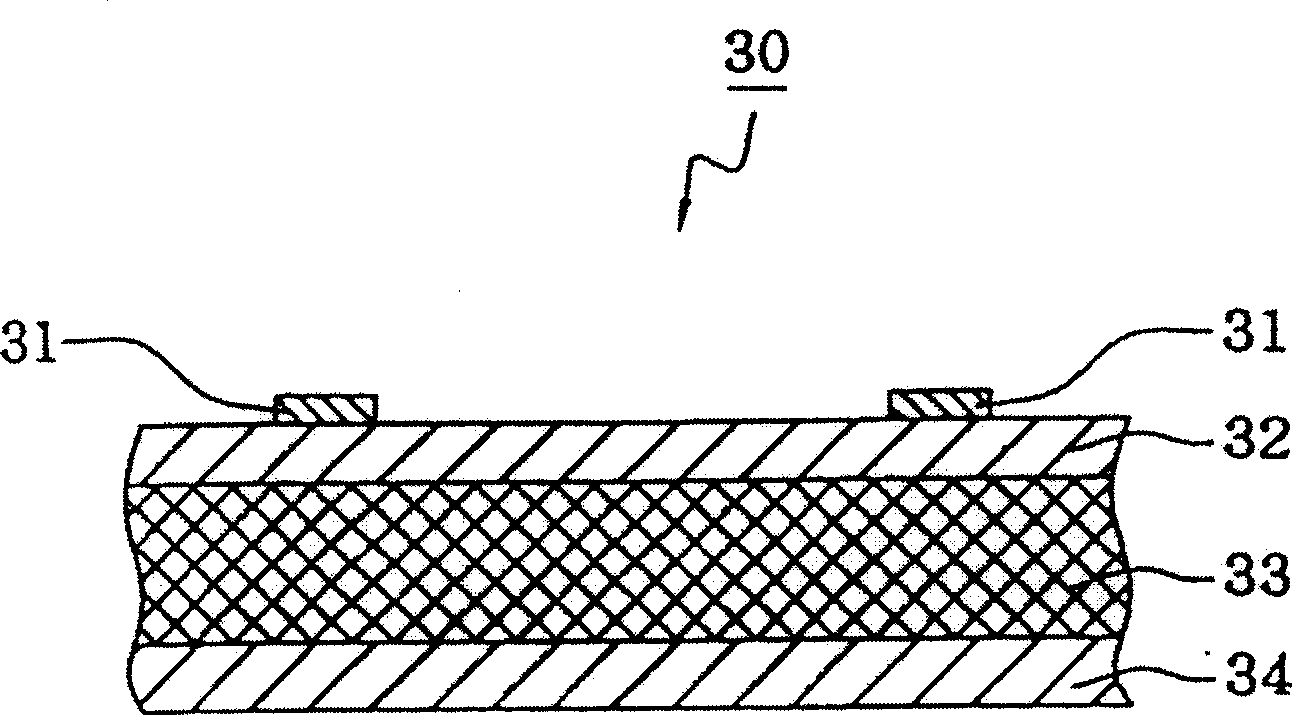

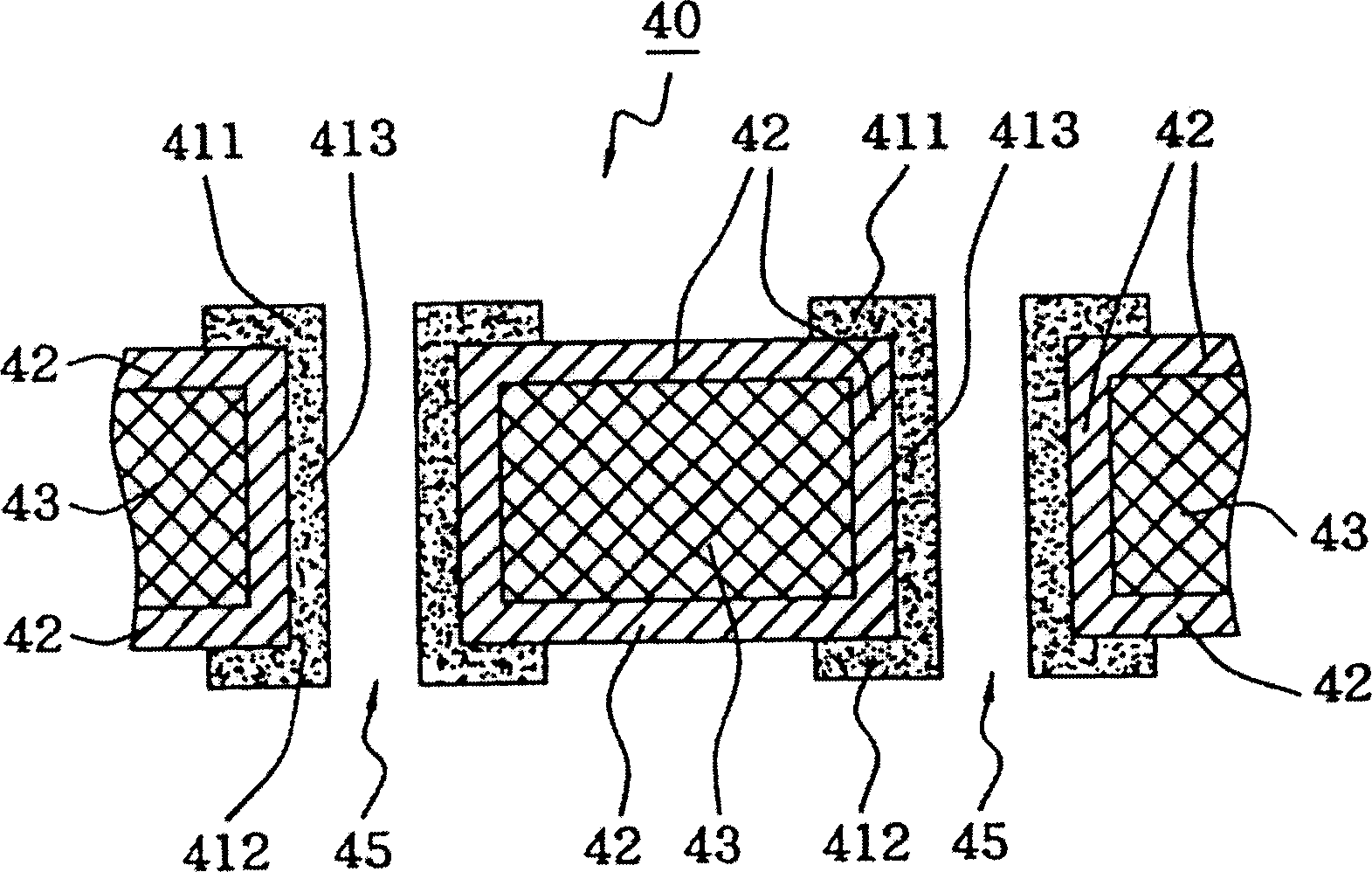

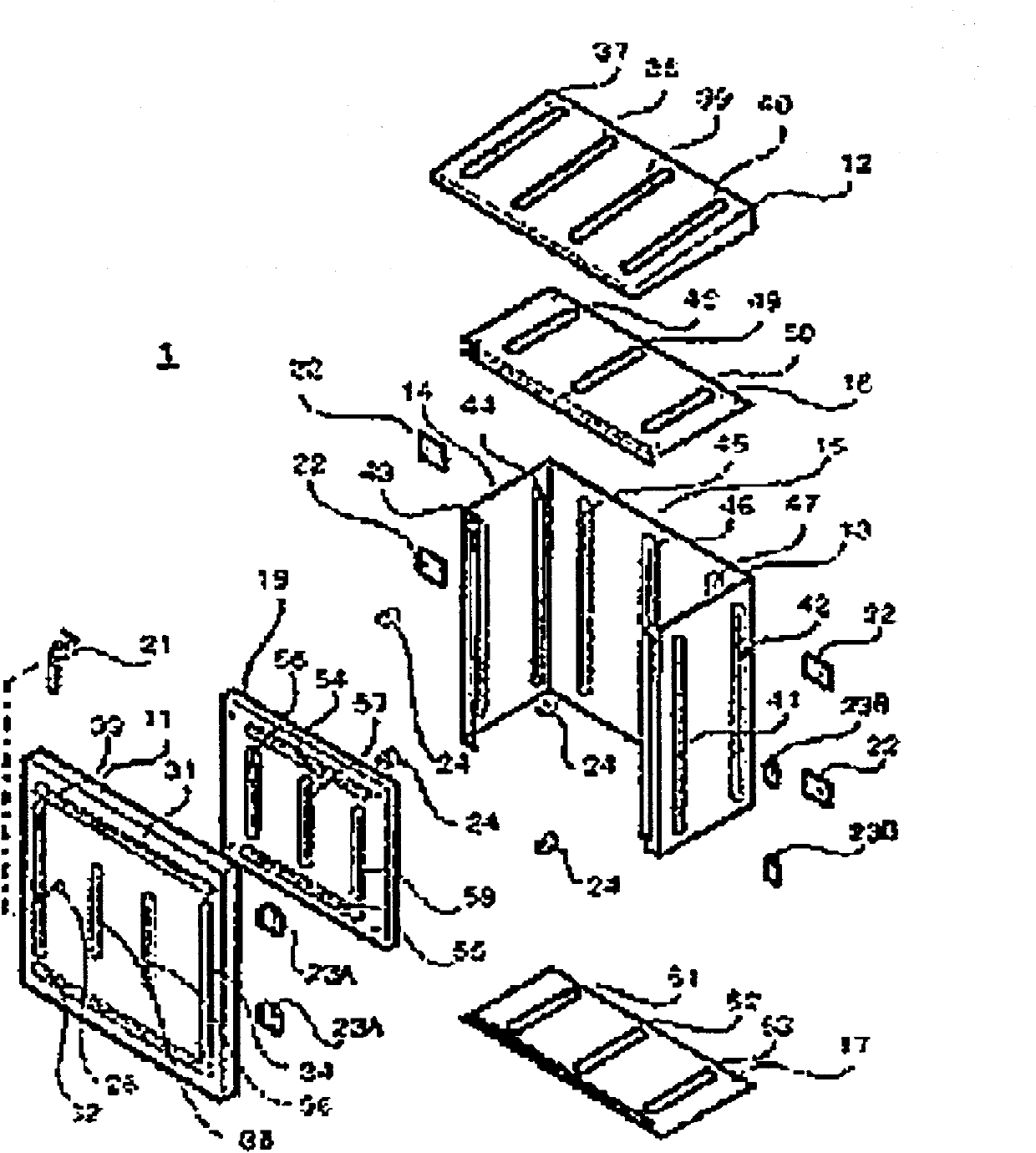

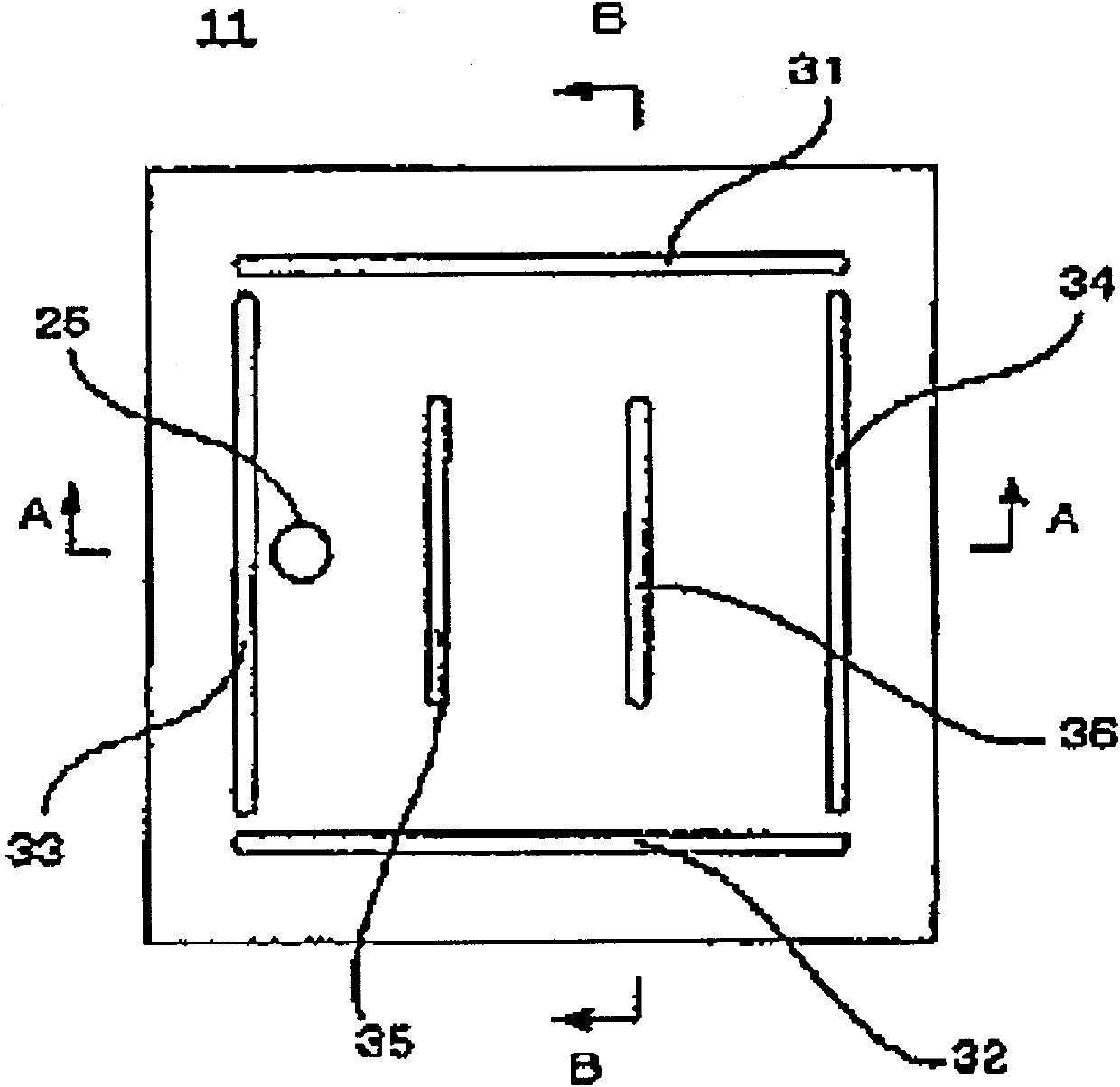

Chip module with high radiating performance and its substrate

InactiveCN1614770AGood cooling propertiesReduce structural weightSemiconductor/solid-state device detailsSolid-state devicesAluminum matrix compositesCopper wire

The chip module consists of a high thermal diffusivity base board, at least one chip mounted on base board. The high thermal diffusivity base board is made by forming insulation layer on metal compound material sheet and then mounting copper wire layer on the insulation layer. The copper wire layer can be used in adhering chip. For the material of base board, the aluminum base with high coefficient of heat-transfer is selected.

Owner:GIGA BYTE TECH CO LTD

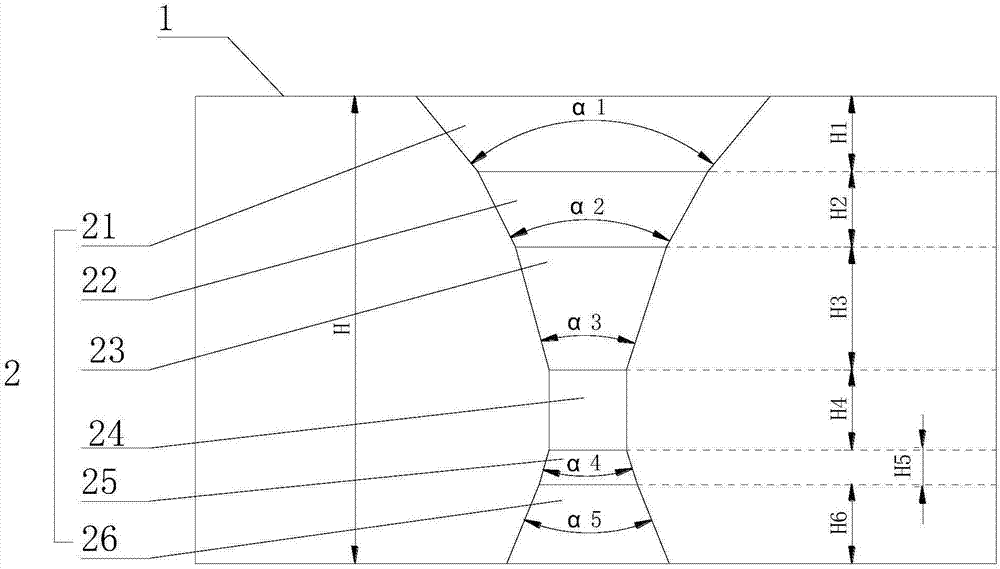

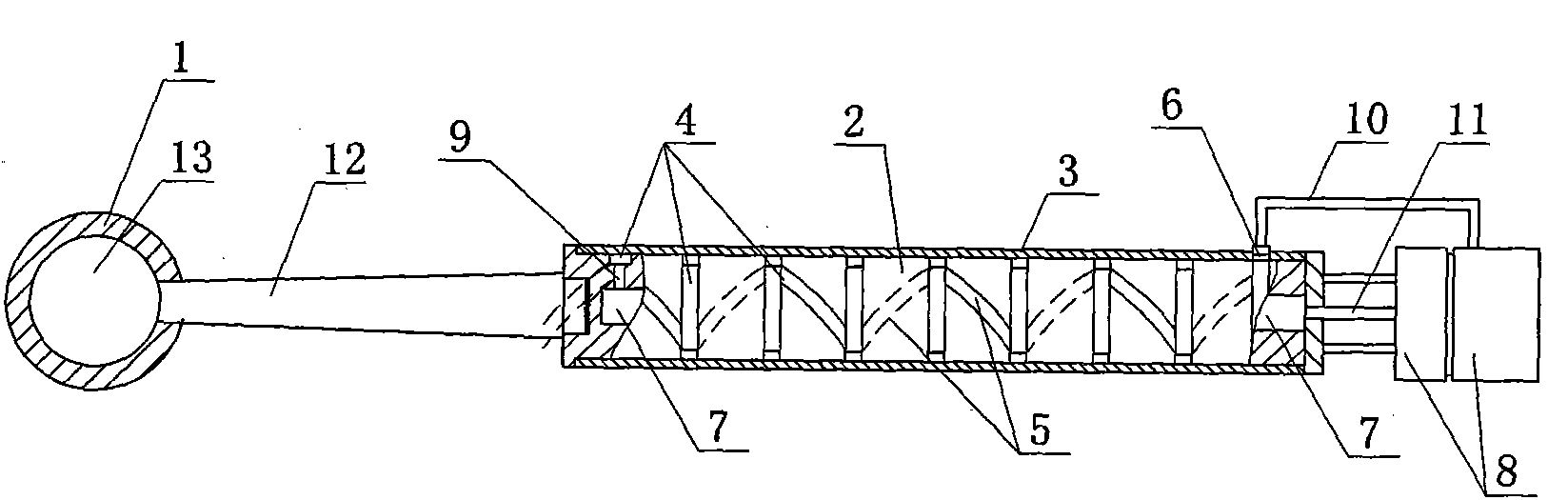

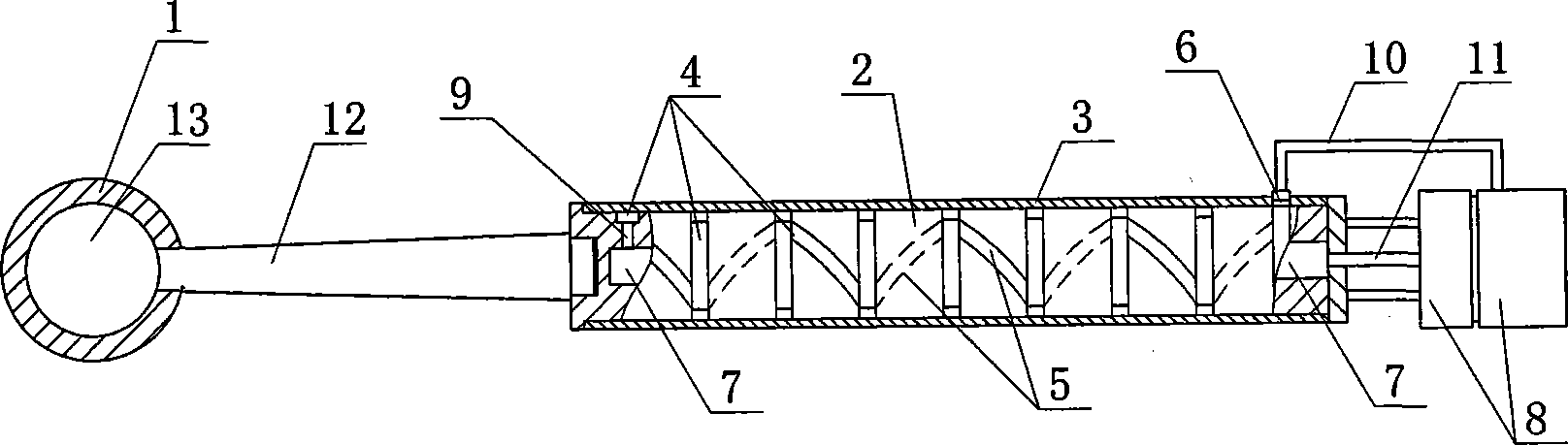

Steel cord wire-drawing die

The invention provides a steel cord wire-drawing die. The steel cord wire-drawing die comprises a die body; a wire drawing hole is formed in the die body; the conical angle of an inlet zone is alpha 1; the conical angle of a lubrication zone is alpha 2; the conical angle of a sizing zone is alpha 3; the conical angle of a decompression zone is alpha 4; the conical angle of an outlet zone is alpha 5; and alpha 1 is greater than alpha 2; alpha 2 is greater than alpha 5; alpha 5 is greater than alpha 3; alpha 3 is equal to alpha 4; the height of the die body is H; the height of the inlet zone is H1; the height of the lubrication zone is H2; the height of a working zone is H3; the height of the sizing zone is H4; the height of the decompression zone is H5; the height of the outlet zone is H6; H3 is greater than H4; H4 is greater than H6; H6 is greater than H2; H2 is equal to H1; and H1 is greater than H5. According to the steel cord wire-drawing die, during wire drawing, stability of a metal wire is increased; the metal wire can transit smoothly, so that the metal wire is not easily broken; thickness of the product is uniform; plastic deformation and elastic deformation of the metal wire are reduced; the conical angle of the working zone is equal to that of the decompression zone, so that reduction and uniform distribution of the friction force are favorably realized during a drawing process of the metal wire; abrasion of a die hole of the wire-drawing die is lowered; heat generated by friction of the metal wire and the die can be dissipated in time; and the service life of the die is prolonged.

Owner:杨飞

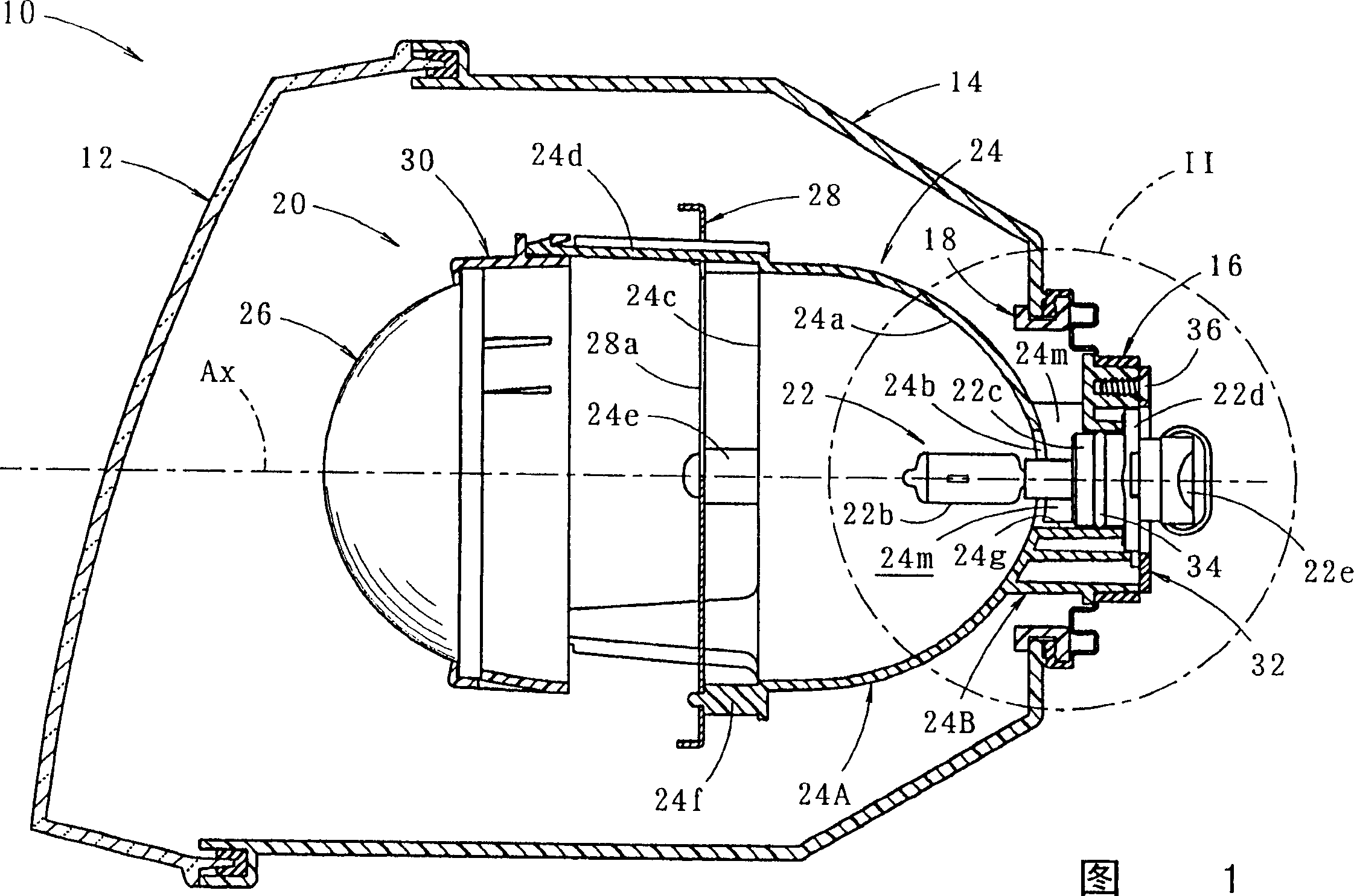

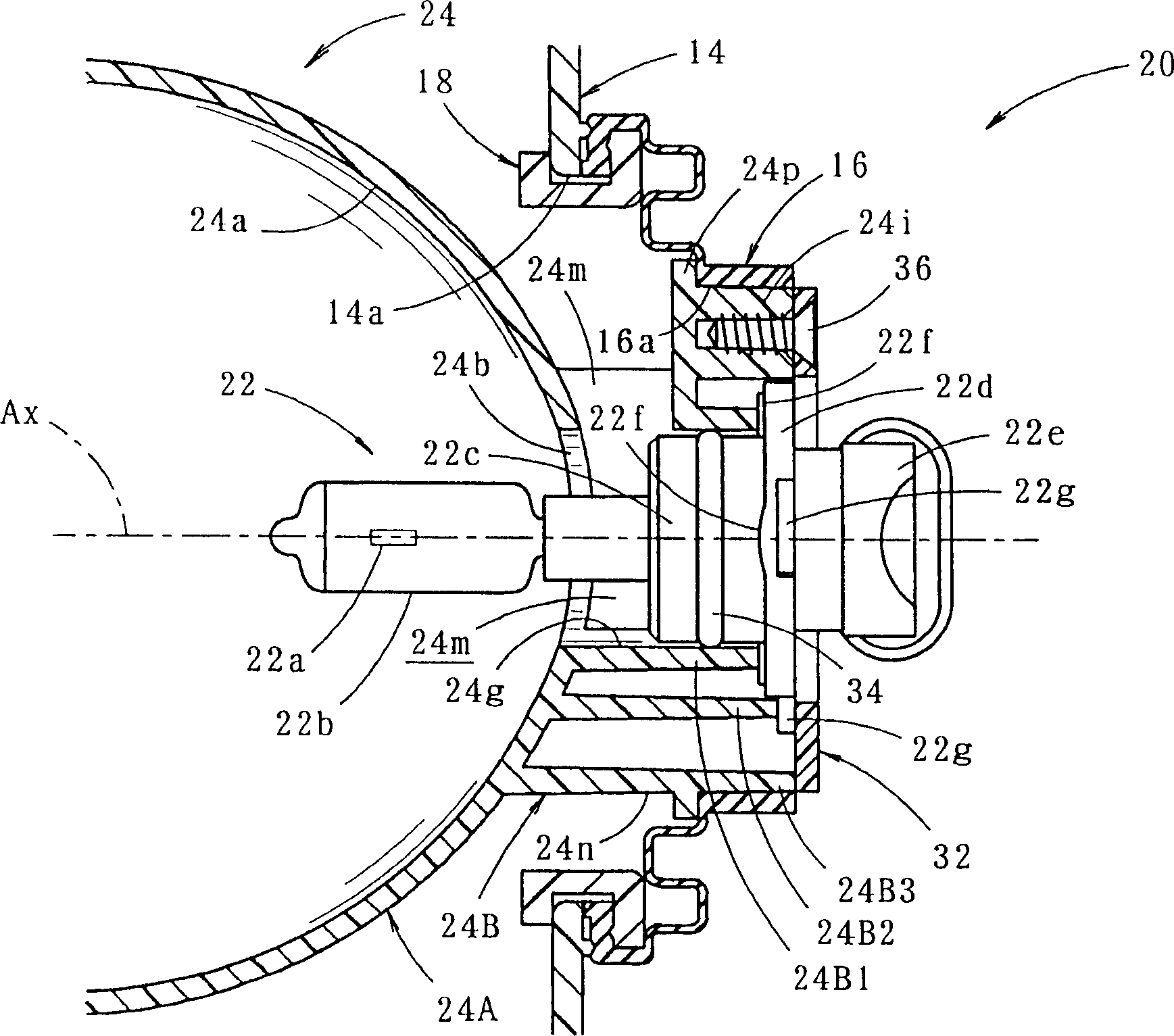

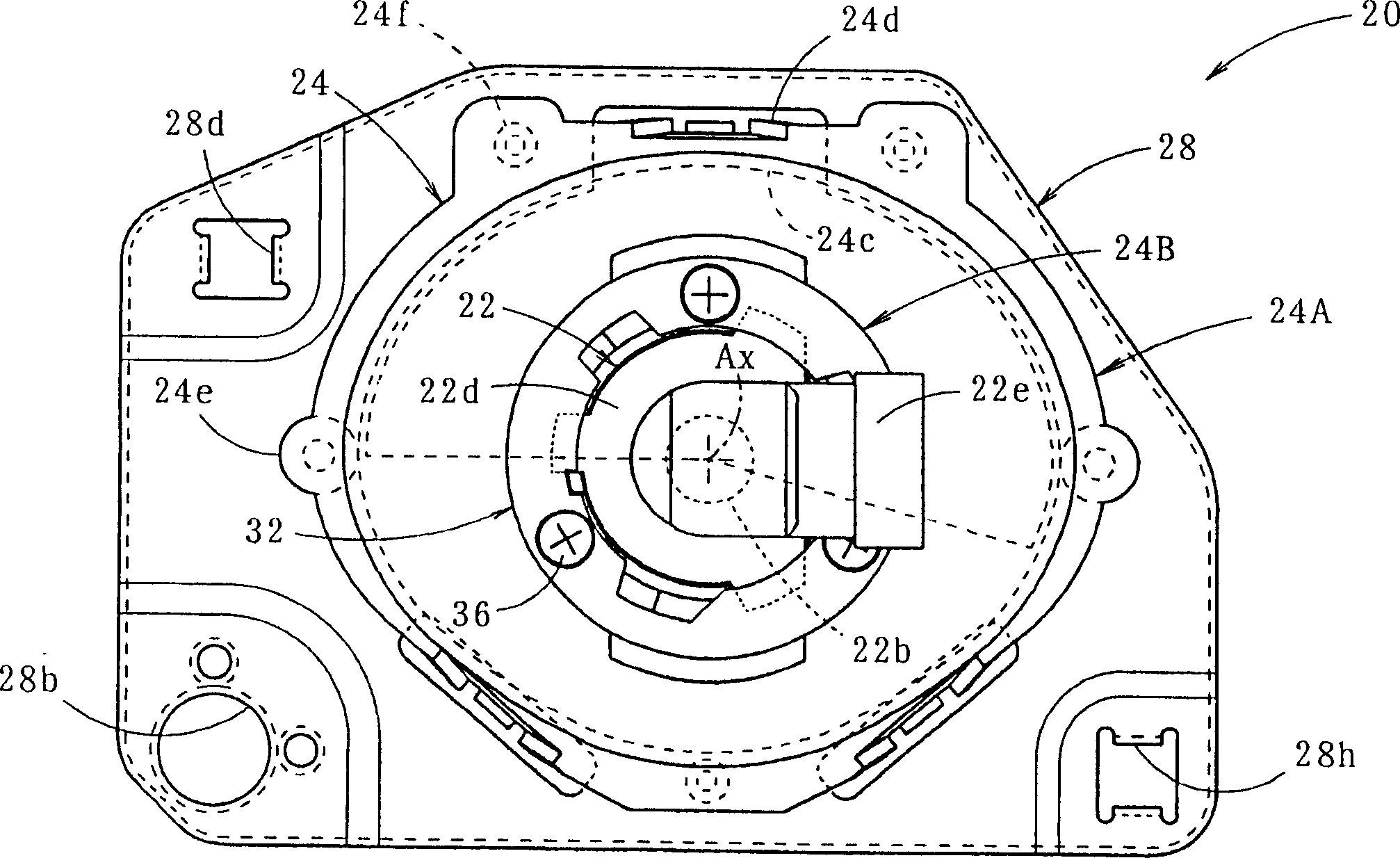

Headlight for vehicle

InactiveCN1380511AEasy to shroud interior spaceAvoid high temperatureVehicle headlampsPoint-like light sourceEngineeringMechanical engineering

A headlamp for vehicles, wherein a body support portion (22c) of a light source bulb (22) is slidingly engaged with an inner peripheral surface of an annular wall (24B) of a reflector (24), and the flange portion (24d) ) abuts against the rear end surface of the annular wall (24B), and in this state, the flange portion (24d) is clamped from the front and rear sides by the annular wall (24B) and the light bulb fixing member (32), thereby placing the light source The bulb (22) is fixed on the reflector (24). Three cutout holes (24m) penetrating through the annular wall (24B) are formed in front of the sliding engagement position between the annular wall (24B) and the body support portion (22c) of the light source bulb (22). The inner space of the reflecting mirror (24) is communicated with the outer space through these cutout holes (24m), and the heat inside the reflecting mirror (24) is dissipated to the outside, which can prevent the high temperature of the reflecting mirror and reduce the possibility of thermal deformation of the reflecting mirror, etc. sex.

Owner:KOITO MFG CO LTD

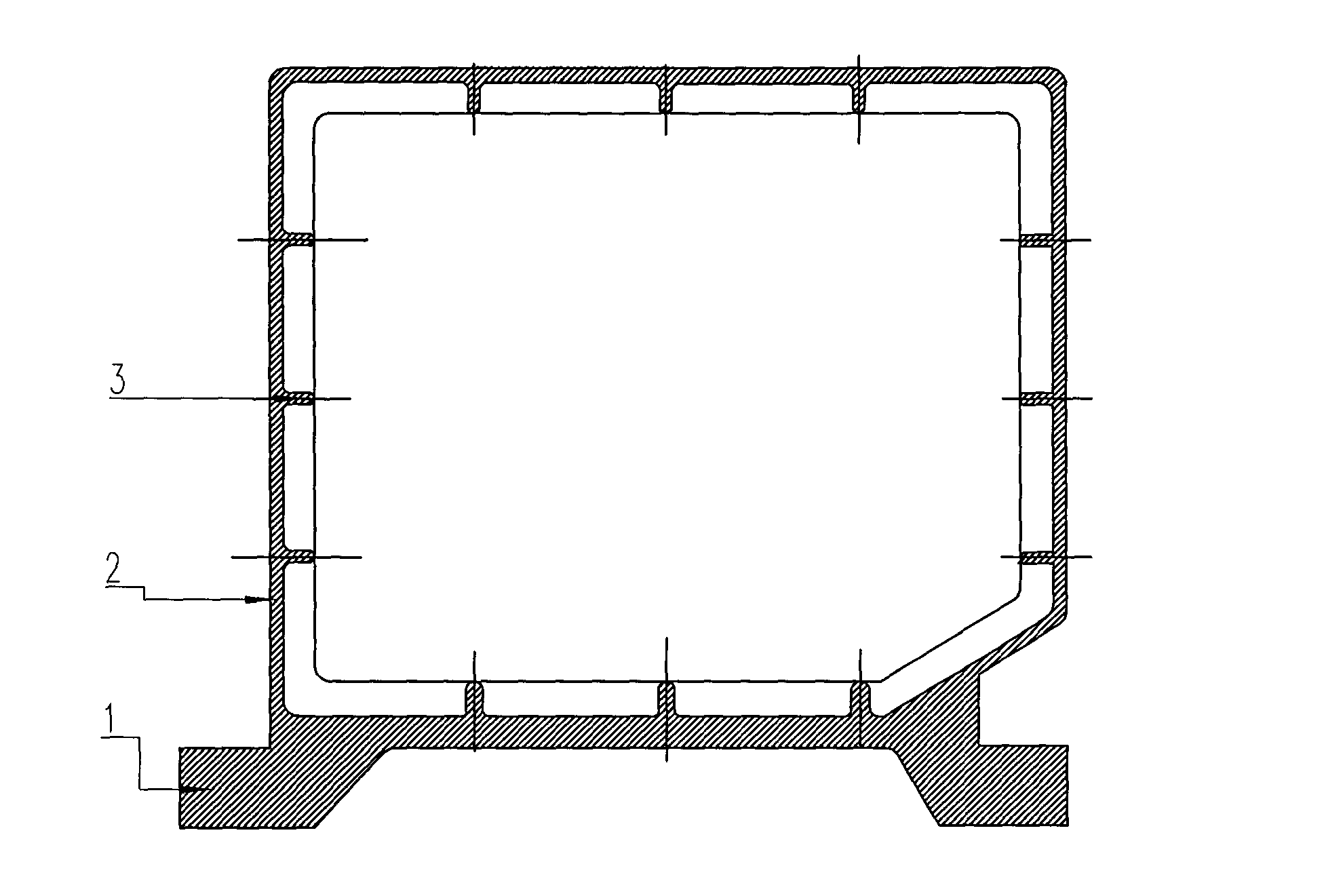

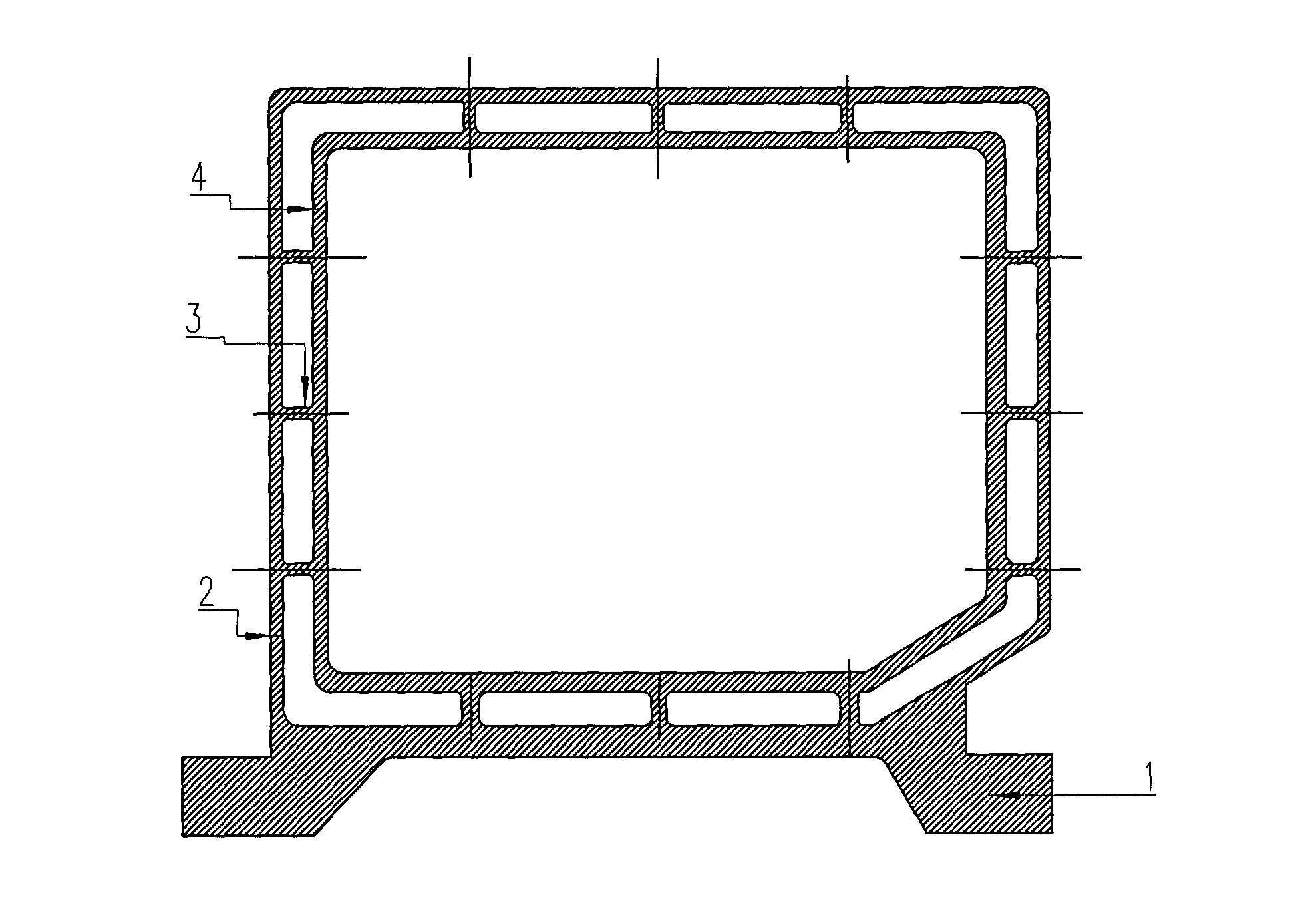

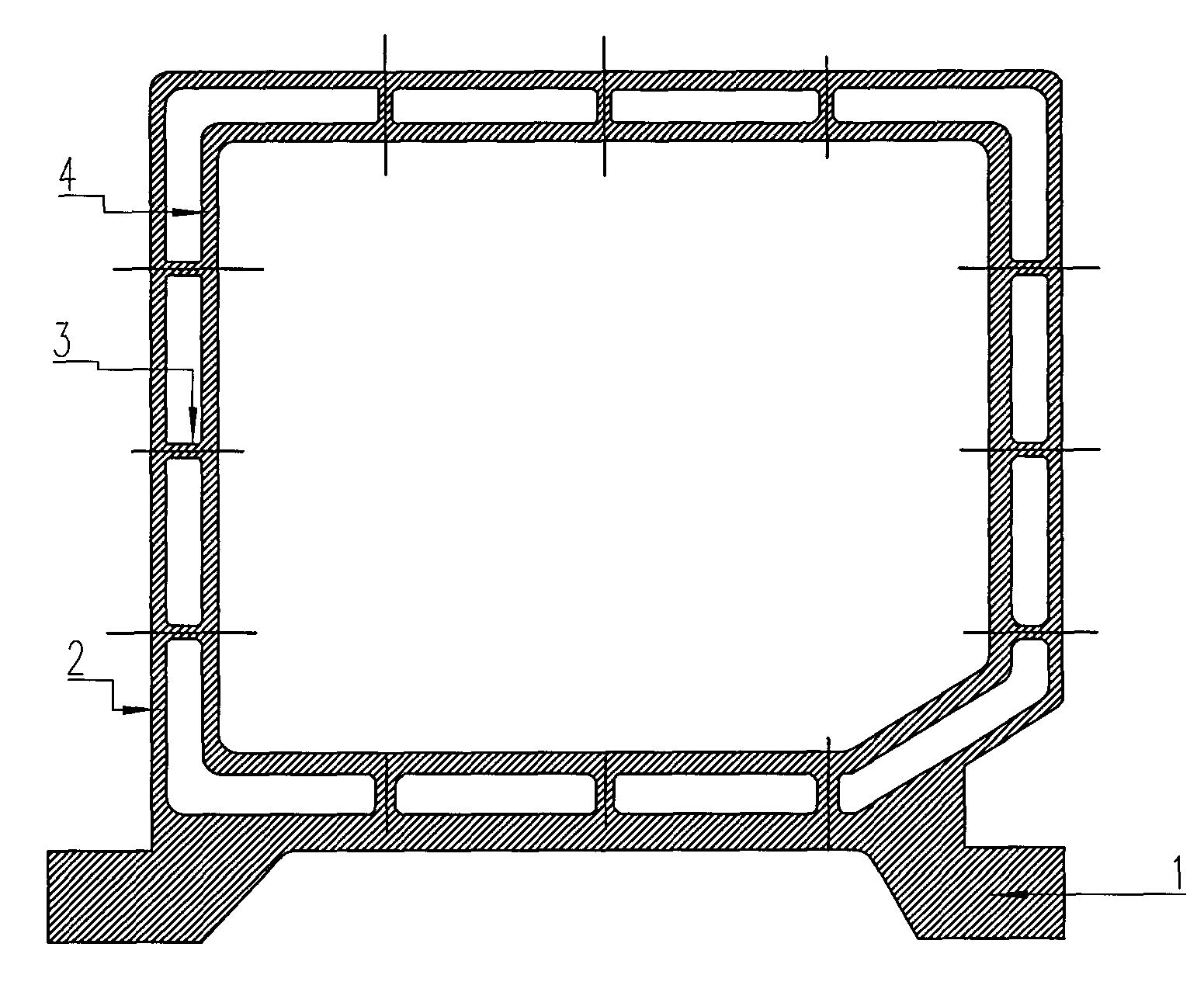

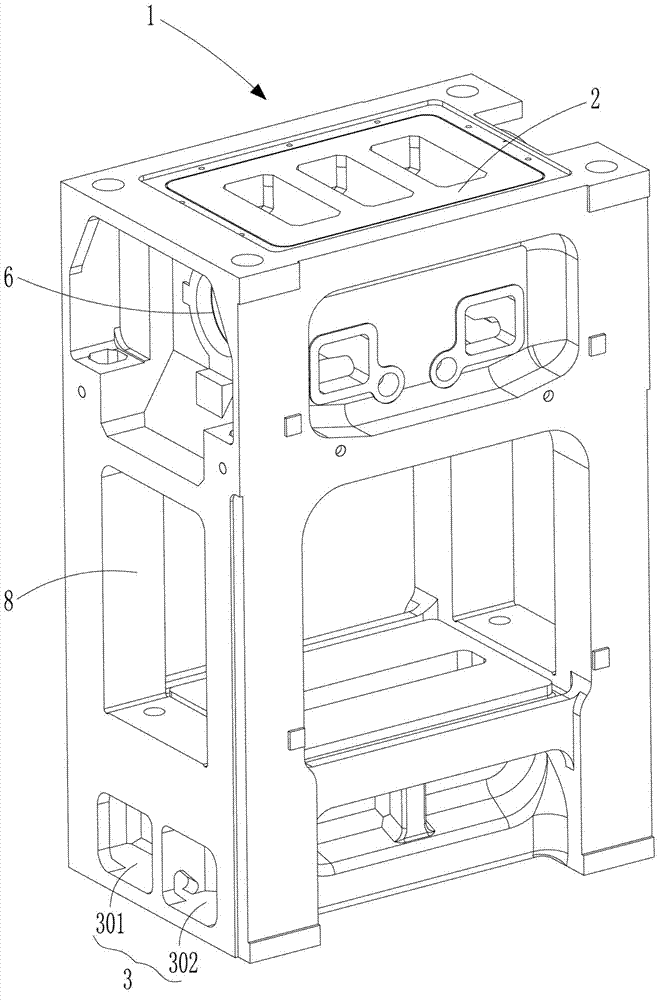

Vertical column structure of numerical control floor-type boring and milling machine

InactiveCN102615511ADoes not affect geometric accuracyImprove rigidityLarge fixed membersNumerical controlDouble wall

A vertical column structure of a numerical control floor-type boring and milling machine comprises a vertical column body, a wall plate, a rib plate and an inner wall plate parallel to the wall plate. One end of the rib plate is connected with the wall plate, and the other end of the rib plate is connected with the inner wall plate. With the double wall plates and 'latticed' ribs, the vertical column structure is domestically initiated, is high in rigidity, is not easy to generate heat deformation when the machine runs, and cannot affect geometric accuracy of the machine.

Owner:武义机床制造有限公司

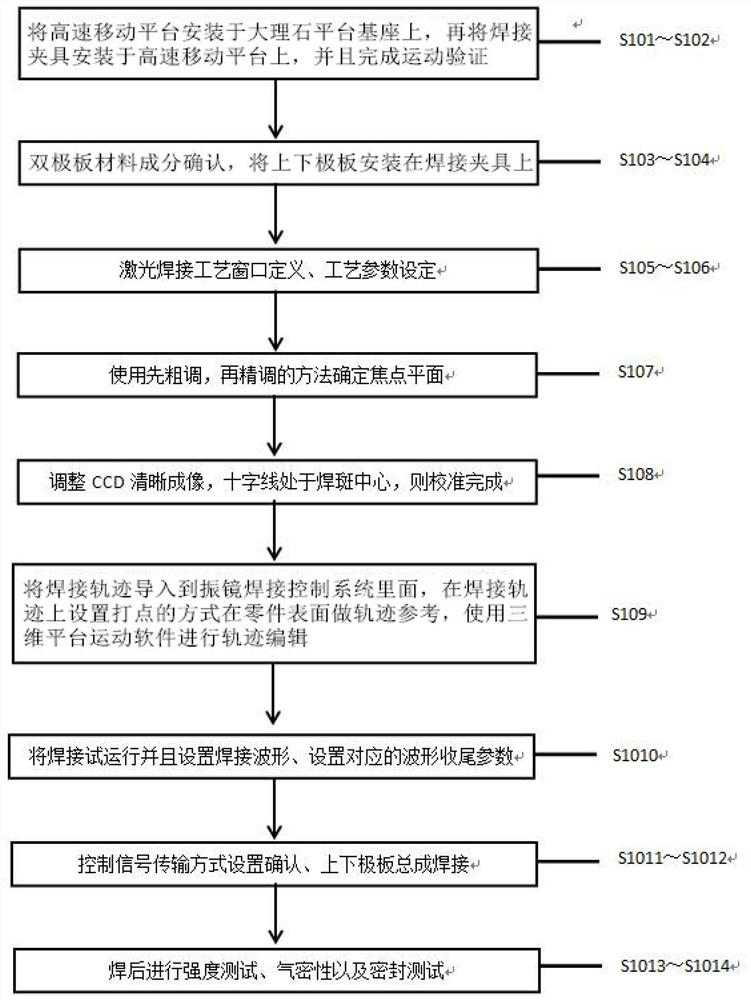

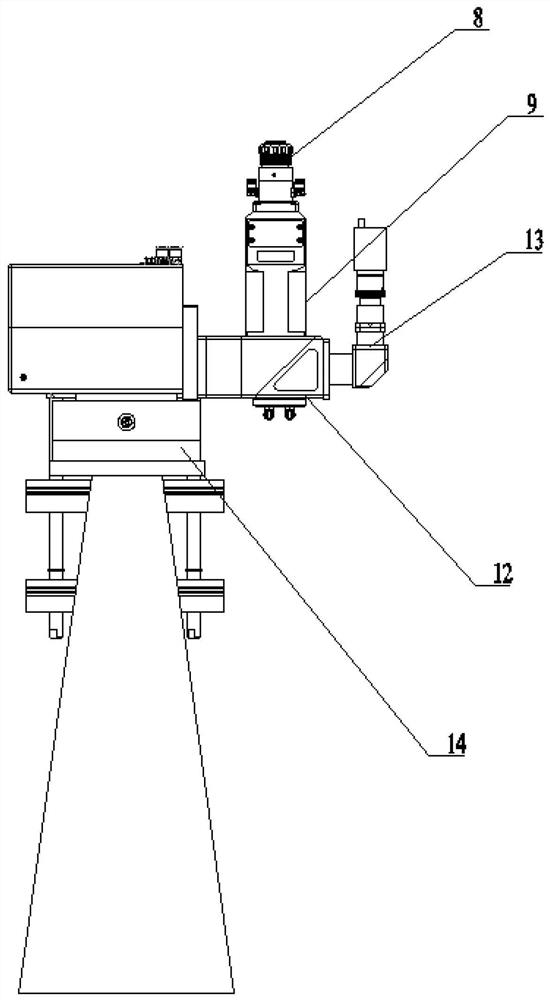

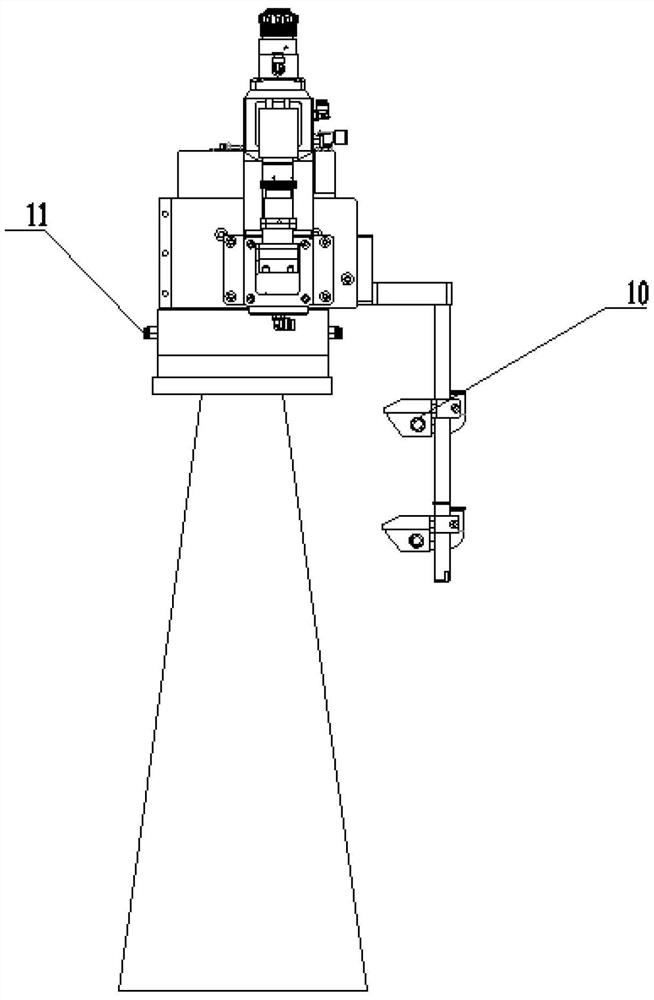

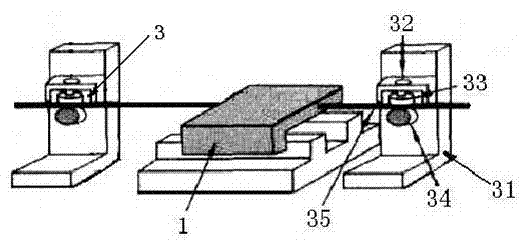

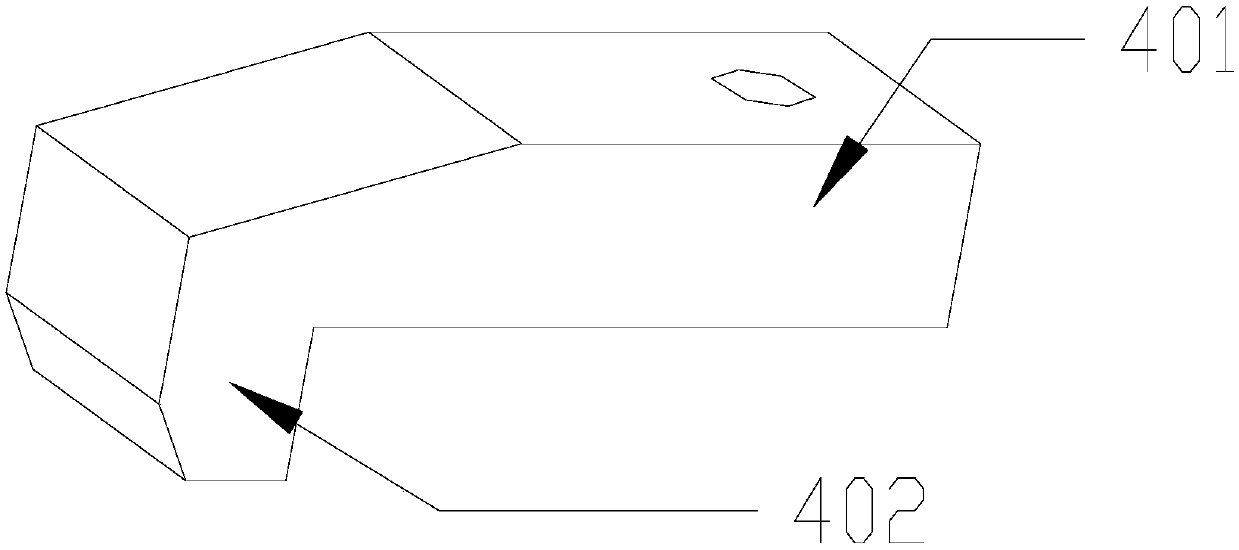

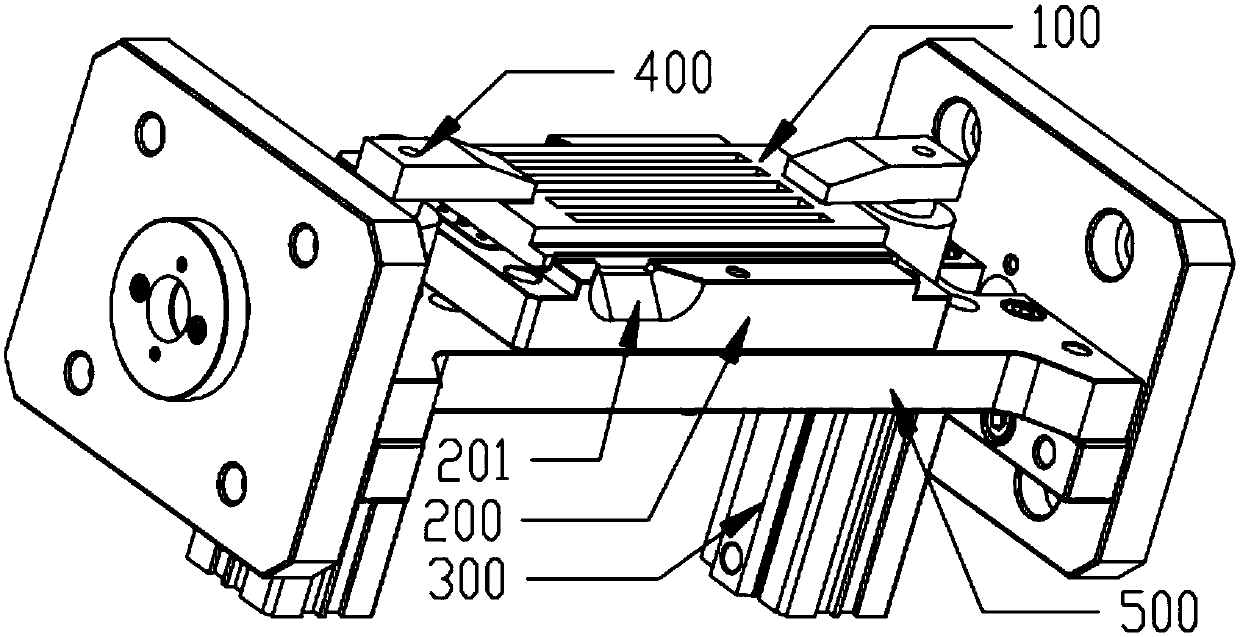

Hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and welding clamp thereof

ActiveCN113020794AIncrease profitIncreased solder contact areaLaser beam welding apparatusUltra high speedHydrogen fuel cell

The invention discloses a hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and a welding clamp thereof, and belongs to the field of hydrogen energy automobile production. A bipolar plate to be welded is included and installed on the welding clamp, the bipolar plate is moved to the mechanical welding position through a high-speed moving platform, characteristic information preset on the bipolar plate is grabbed after photographing and compared with characteristics in a photographing template, a laser beam passes through an axial lens of a galvanometer, a second shaft of the galvanometer drives the laser beam to move to the welding track end point from the welding track starting point, a complete welding line is finally formed along with movement of the galvanometer, an upper single-pole plate and a lower single-pole plate are welded together, and welding of the bipolar plate is achieved. When the process is used for welding the bipolar plate, the welding process and the welding line width are extremely stable, obvious fluctuation is avoided, the pseudo soldering problem is not likely to happen, the welding strength is high, the welding line is flat, the overcurrent capacity of the welding line is guaranteed, and the product performance of a hydrogen fuel cell is greatly improved.

Owner:龙俊耀

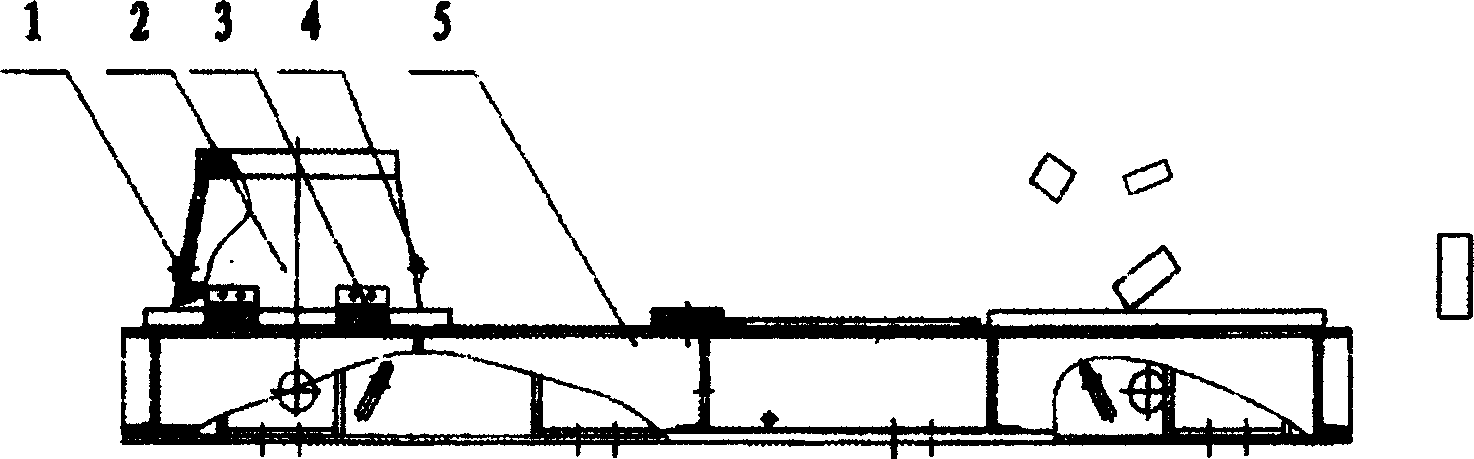

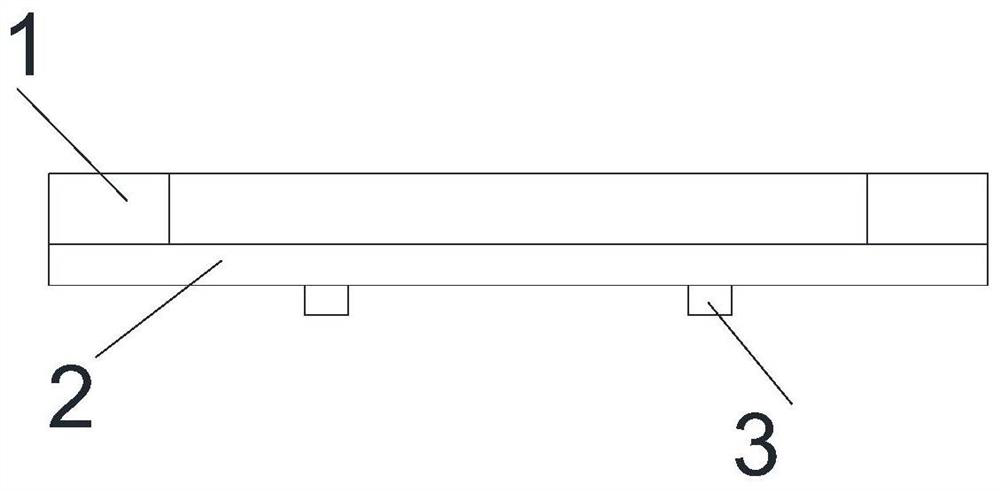

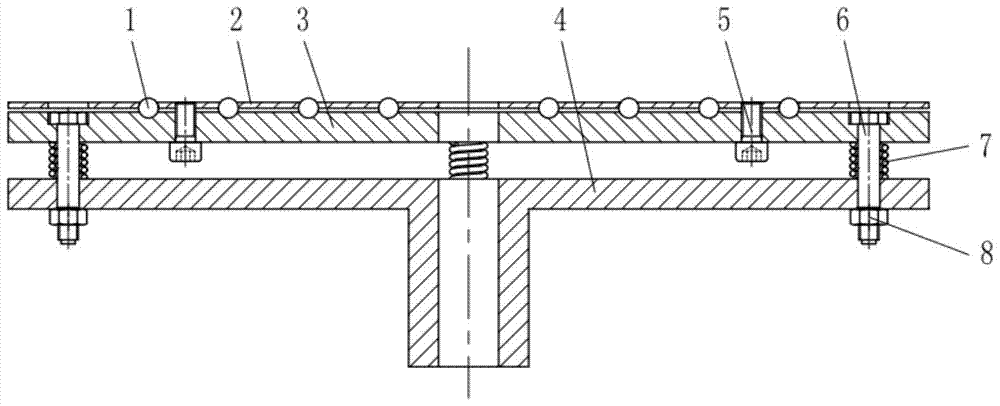

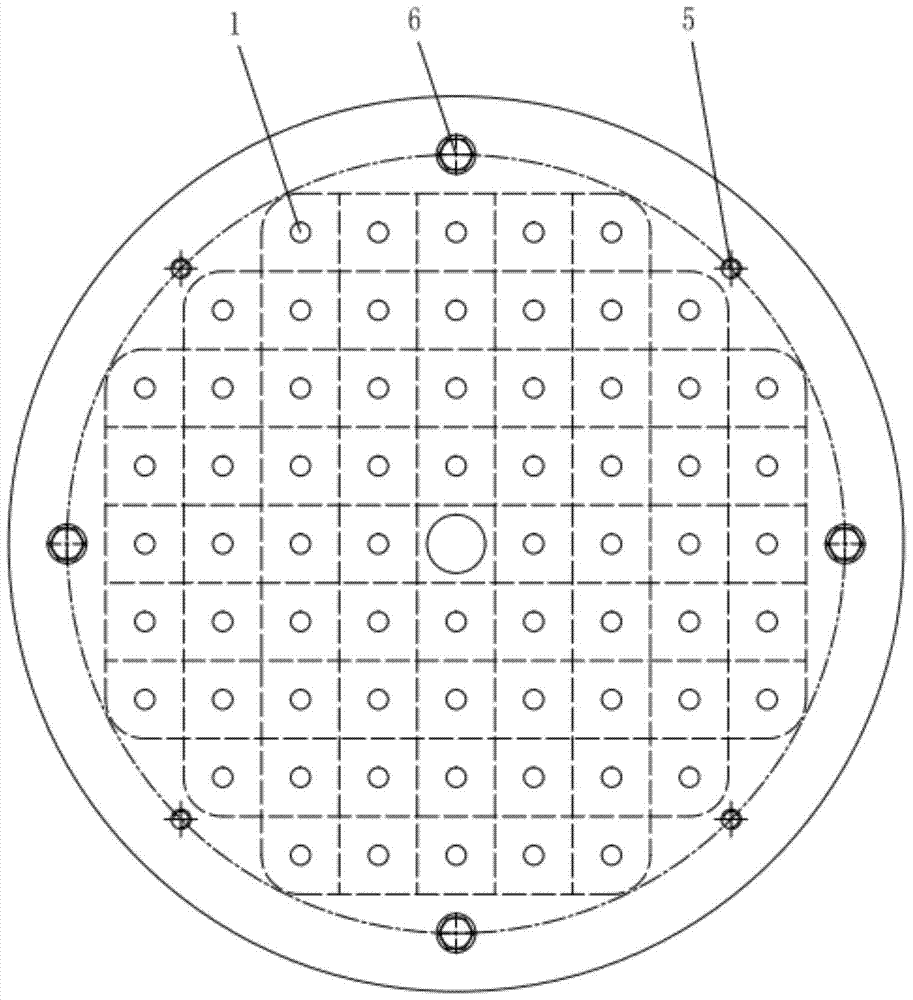

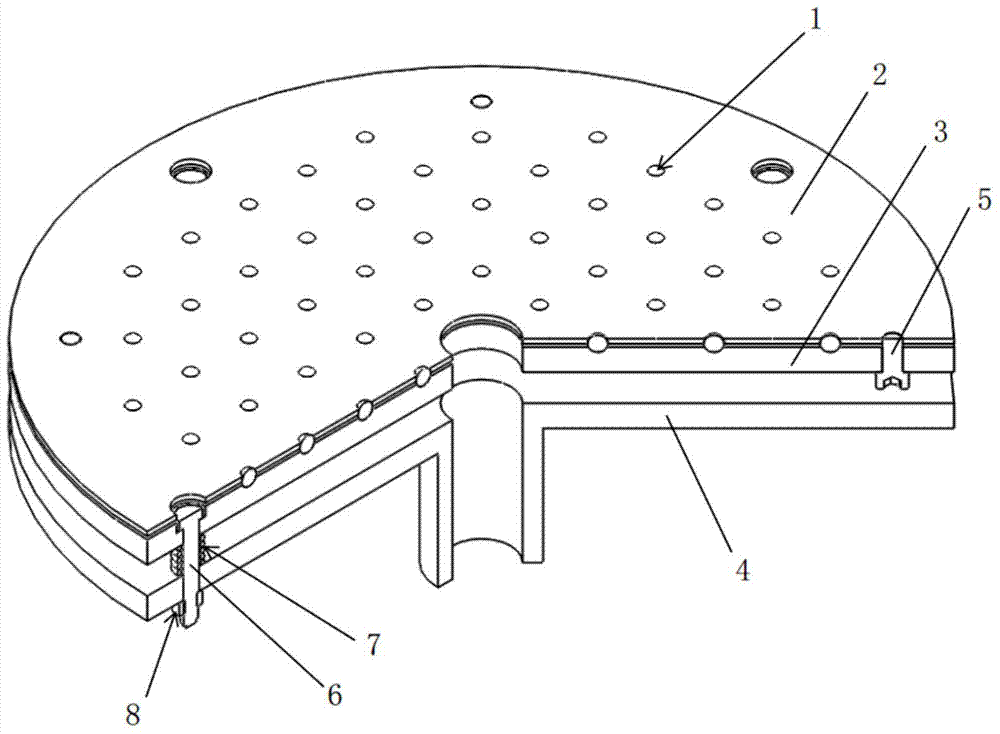

Novel workbench driven by friction pull rod

The invention discloses a novel workbench driven by a friction pull rod. The novel workbench comprises a light workbench body, granite guide rails and driving mechanisms, the light workbench body is arranged above the granite guide rails in a floating manner, each driving mechanism comprises an L-shaped baseplate, a C-shaped preloading plate is mounted on a vertical plate of each L-shaped baseplate, an air cushion and a motor friction wheel are sequentially mounted below each C-shaped preloading plate, and a traction rod is arranged between each air cushion and the corresponding motor friction wheel and connected with the light workbench body. The novel workbench driven by the friction pull rod is good in rigidity, long in working stroke, high in positioning accuracy and less prone to thermal deformation.

Owner:苏州凯欧机械科技有限公司

High temperature screw pump

ActiveCN1603622ANot prone to thermal deformationAvoid deformationRotary piston pumpsRotary piston liquid enginesChemical industryThermal state

The invention involves a kind to be possible completely to substitute the petroleum chemical industry enterprise to refine oil in the installment centrifugal pump, the reciprocating pump or imports the screw rod to pump, and has thermostablly may reach 450deg.C, the performance stably, safe is reliable, the economical highly effective high temperature screw rod pumps. It both does not have the centrifugal pump to pump out the phenomenon, and has overcome the reciprocating pump service work load in a big way, overhaul period long characteristic, and the thorough settlement tradition double screw rod has pumped when transports above 300deg.C the high temperature medium the pump body is easy to appear the thermal deformation, causes to pump holds the axis, pumps the end surface and the mechanical seal divulges as well as pumps the association with the electricity association when the thermal state must readjust to the medium a series of questions. Its unique feature is: 1. The pump body uses opens the type structure, by foundation strut seat stay, but the bearing seat also is shoulders through the pump body, like this guaranteed has pumped cannot interfere with the normal work under the high temperature operating mode as a result of the pipeline thermal deformation; 2. Uses the collection attire type bearing gear structure, the bearing riggers band entire package water cooling, causes the bearing gear not the high temperature environment influence; 3. The host, all uses three struts localizations from the moving axis and the wing nut. When pumps suitablly uses in the higher working pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated high-speed punch press body

ActiveCN103692687ASolve the problem of damaged oil leakageUniform temperaturePressesEngine lubricationPunch pressThermal deformation

The invention discloses an integrated high-speed punch press body. The whole punch press body is integrally cast and comprises a main body, a crank case arranged on the main body, a main oil tank and an auxiliary oil tank, wherein the main oil tank and the auxiliary oil tank are arranged on the main body. The main body is provided with four stand columns, and cavities are formed inside the stand columns to form oil return pipes which communicate the main oil tank and the crank case as well as the auxiliary oil tank and the crank case; a bearing block is arranged inside the crank case; an oil channel which communicates the insides of the main oil tank and the auxiliary oil tank is arranged between the main oil tank and the auxiliary oil tank. Being integrally formed through the casting technology, the whole integrated high-speed punch press body is better in integral rigidity and accordingly solves the influence of assembly errors on precision; the oil return pipe of lubricant oil is integrated inside the integrated punch press body and accordingly is fully sealed without contact with joint guide pipes, further the problem of breakage and oil leakage of the guide pipes can be solved; besides, the thickness of the oil return pipes is larger than the diameter of traditional rubber pipes, so that oil return can be more smooth; the oil tank channel achieves mixing and circulation of the lubricant oil in the main oil tank and the auxiliary oil tank, so that the temperature of every portion of a punch press can be uniform and further thermal deformation can be avoided.

Owner:苏州欧利锦高速精密冲床科技有限公司

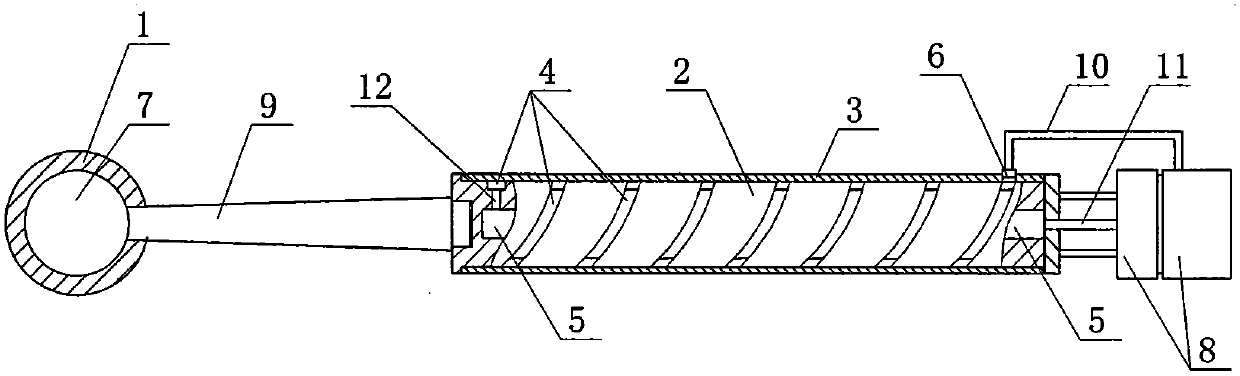

Glass gathering rod

InactiveCN103395967ARealize circulating water coolingImprove cooling effectGlass making apparatusInlet channelThermal deformation

The invention disclose a glass gathering rod, comprising a comprising a gathering rod body and a gathering ball which are connected with a glass gathering machine, wherein the gathering rod body is composed of a conical rod section and a straight rod section which are connected together in a detachable manner; a gathering ball is detachably connected at the front end of the conical rod section; the straight rod section comprises a core shaft; the outer surface of the core shaft is provided with a plurality of circular grooves; a shaft section of the core shaft between two adjacent circular grooves are a communicated section; the surface of the communicated section is circularly provided with a plurality of communication grooves for communicating two adjacent circular grooves; a shell in a close fit relationship with the outer surface of the core shaft is tightly sleeved on the core shaft; the shell encloses the circular grooves into a plurality of circular water inlet channels and encloses the communication grooves into a communication water channel; the core shaft is provided with a water outlet; a circular water inlet channel at the forefront end is communicated with the water outlet; and the back end part of the shell is provided with a water inlet communicated with a circular water inlet channel at rearmost end. The glass gathering rod has a good cooling effect and cannot generate thermal deformation easily.

Owner:高密圣泰机电科技有限公司

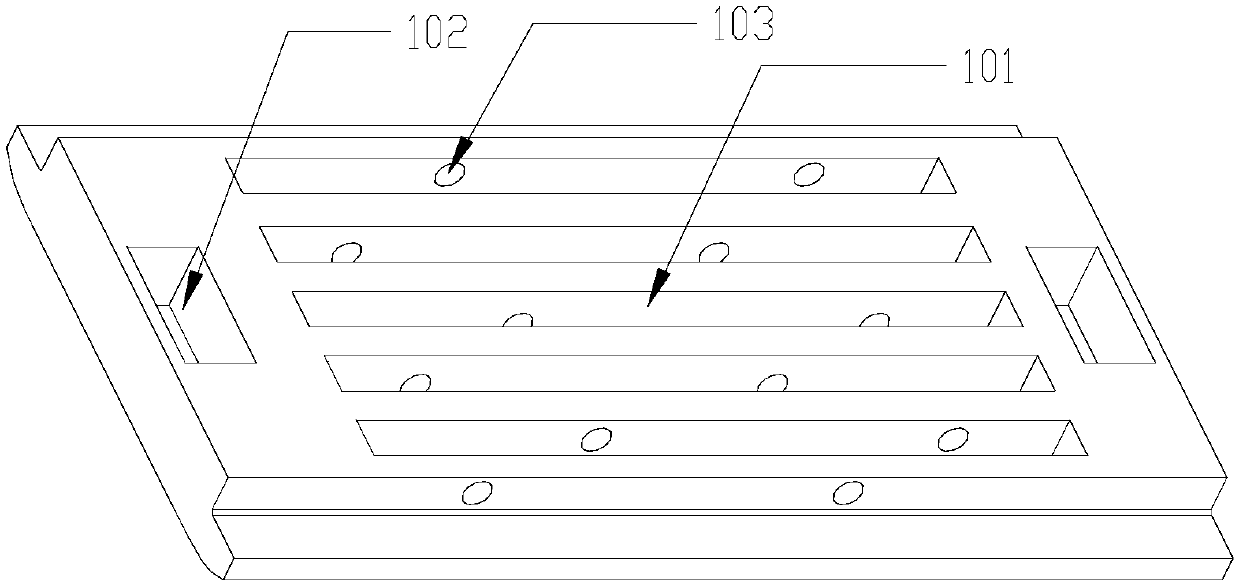

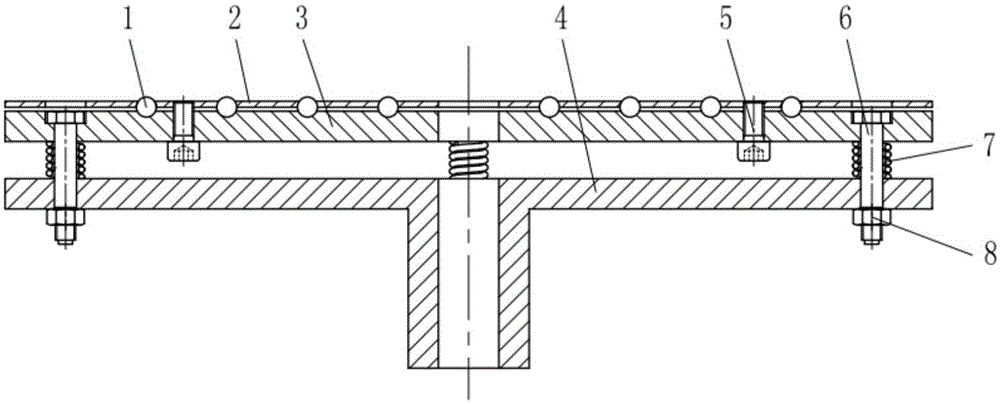

Positioning jig for numerical control machining thin-wall product side holes

ActiveCN107838705ANot prone to thermal deformationPositioning apparatusMaintainance and safety accessoriesNumerical controlMachine parts

The invention discloses a positioning jig for numerical control machining thin-wall product side holes. The positioning jig for numerical control machining the thin-wall product side holes comprises abase, a positioning block, a rigid protection plate and a cooling device. The base is arranged on a numerical control machine tool; the positioning block is fixed on the base; a machined part is clamped onto the positioning block; processing slots are formed in two horizontal side faces of the positioning block; the rigid protection plate is made of porous aluminum materials; a plurality of rectangular heat-radiating slots are formed in the rigid protection plate along a length direction in a penetrating way; a plurality of circular through holes are formed in slot walls of two sides of the heat-radiating slots; the through holes in each two adjacent slot walls are formed in a staggering way and are used for communicating spaces of each two adjacent heat-radiating slots; and the cooling device comprises a water tank, a water pipe and a nozzle. According to the positioning jig adopted by the invention, heat on the machined part can be radiated conveniently, so that the machined part isnot easy to deform by heating.

Owner:苏州海盛精密机械有限公司

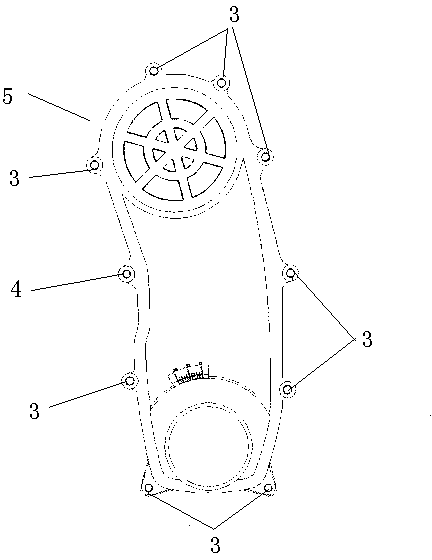

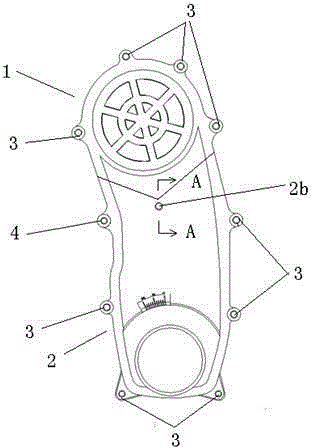

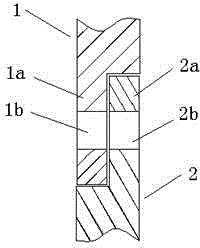

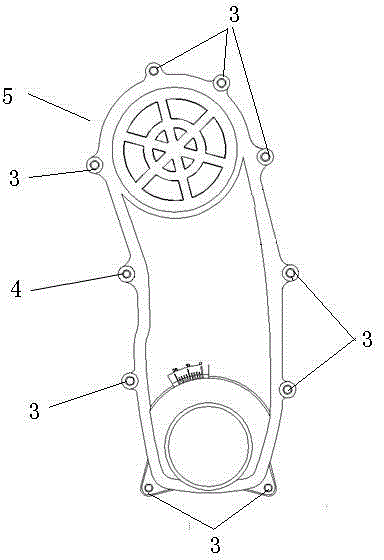

Correct timing cover piece of motor

ActiveCN103161602AReduce workloadReduce maintenance costsCasingsValve arrangementsEngineeringCamshaft

The invention relates to a correct timing cover piece of a motor. The cover piece is characterized in that an installation support lug and a water pump installation support lug are installed on the edge of the cover piece, the cover piece is formed by an upper correct timing cover piece and a lower correct timing cover piece in an overlap joint mode, a first overlap-joint step is installed on the overlap-joint edge of the upper correct timing cover piece and a second overlap-joint step is installed on the overlap-joint edge of the lower correct timing cover piece. The upper correct timing cover piece and the lower correct timing cover piece are connected in the overlap joint mode through the first overlap-joint step and the second overlap-joint stage. The first overlap-joint stage is provided with a first water pump installation hole, the second overlap-joint stage is provided with a second water pump installation hole, and after the upper correct timing cover piece and the lower correct timing cover piece are connected in the overlap-joint mode, the first water pump installation hole and the second water pump installation hole are overlapped. The water pump installation support lug is located on the lower correct timing cover piece, a length ratio of the upper correct timing shroud cover piece and the lower correct timing cover piece is 2-4: 6-8. The correct timing cover piece of the motor has the advantages of enabling a correct timing adjustment of the motor and maintaining of a camshaft gear train to be convenient.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

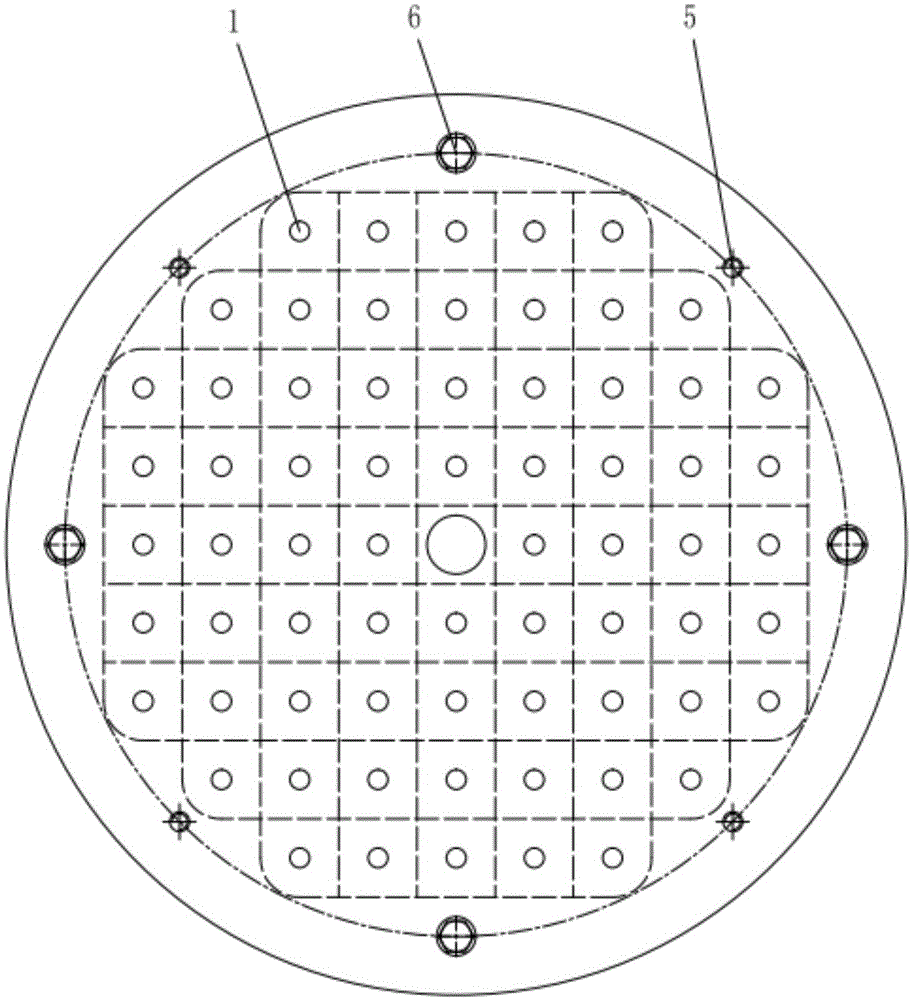

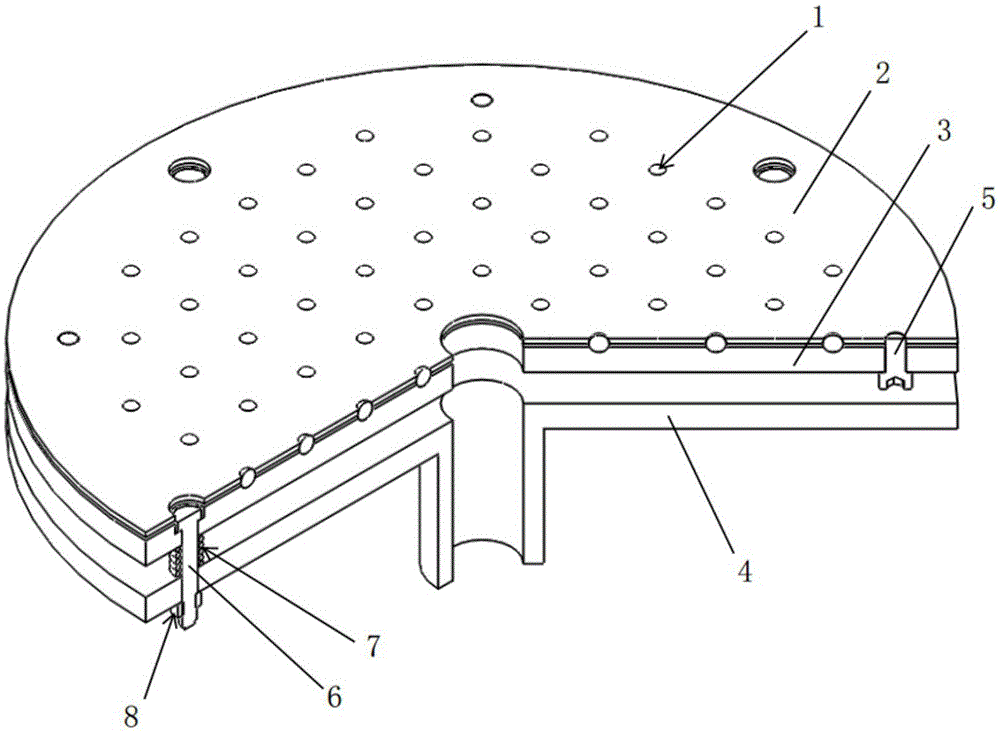

Modified planar rolling method and device

ActiveCN105058229AImprove uniformityNot prone to thermal deformationBurnishing machinesMachined surfaceThermal deformation

Disclosed is a modified planar rolling method. The planar rolling method comprises the steps that a workpiece is attached under a planet wheel and makes contact with balls arranged on an upper grinding disk; the workpiece applies load to the planet wheel; the upper grinding disk tends to move downwards under the action of the rolling load; when the rolling load exceeds the pretightening force of springs, the upper grinding disk moves downwards continuously along bolts and the pretightening force also increases gradually until the pretightening force is in balance with the rolling load; the springs in a compression state are capable of providing restoring force and self-adaptively adjusting the contact state of the balls and the surface of the workpiece; the workpiece is in a rotation and a revolution along with the planet wheel; and the balls on the upper grinding disk roll the surface of the workpiece again and again and even rolling tracks are left on the surface. The invention further provides a rolling grinding device for achieving the planar rolling method. The modified planar rolling method is good in uniformity and relatively high in machining precision; the thermal deformation of the machined surface is not prone to occurring.

Owner:湖州优研知识产权服务有限公司

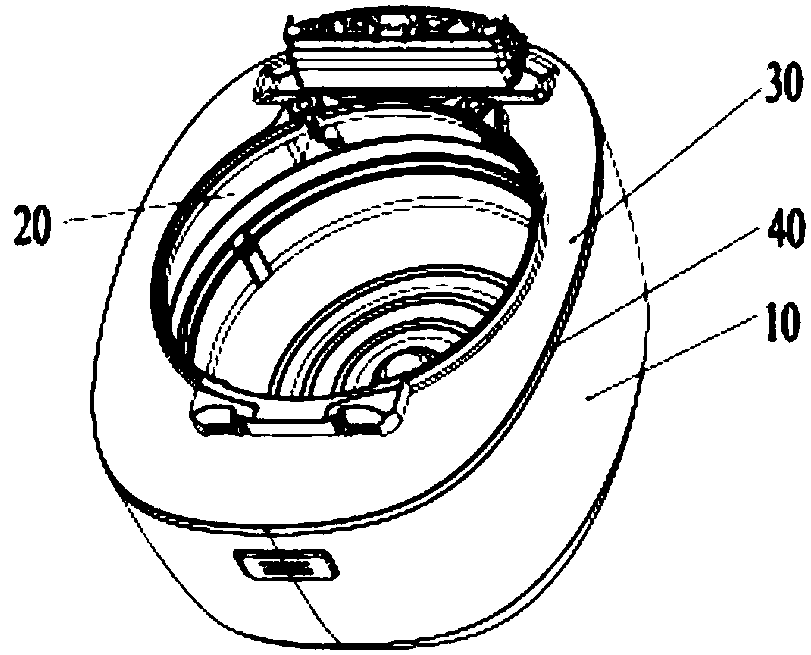

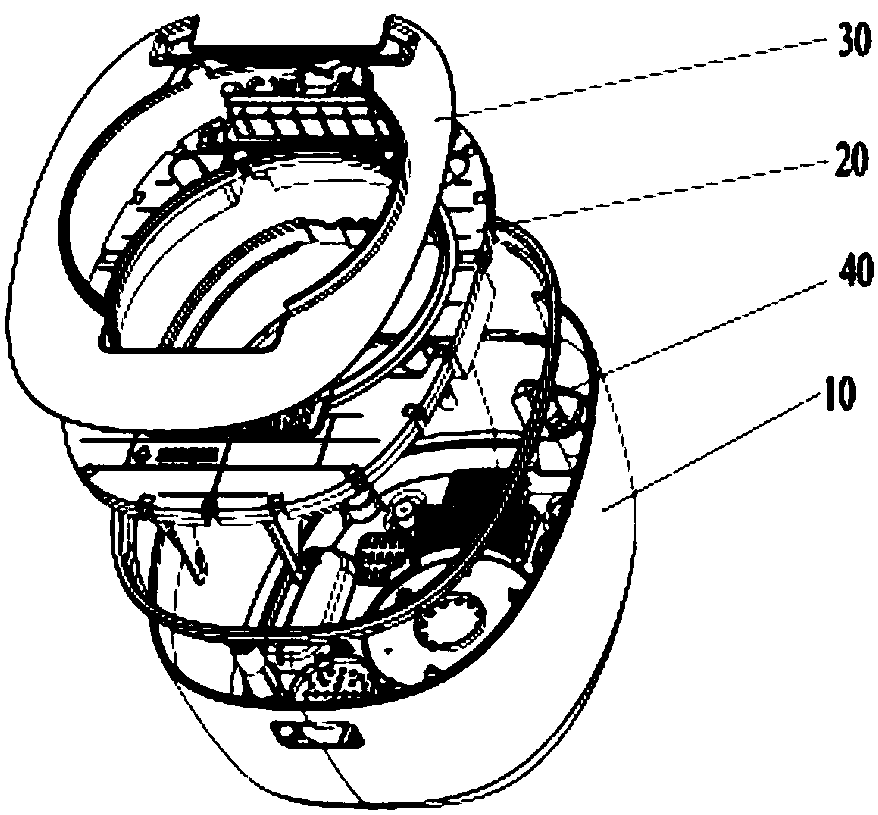

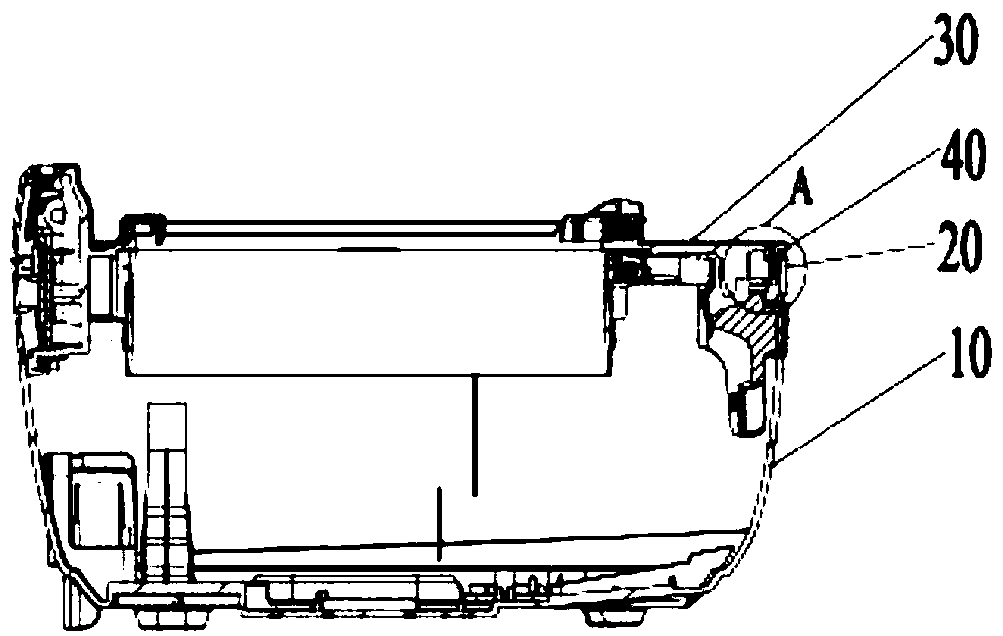

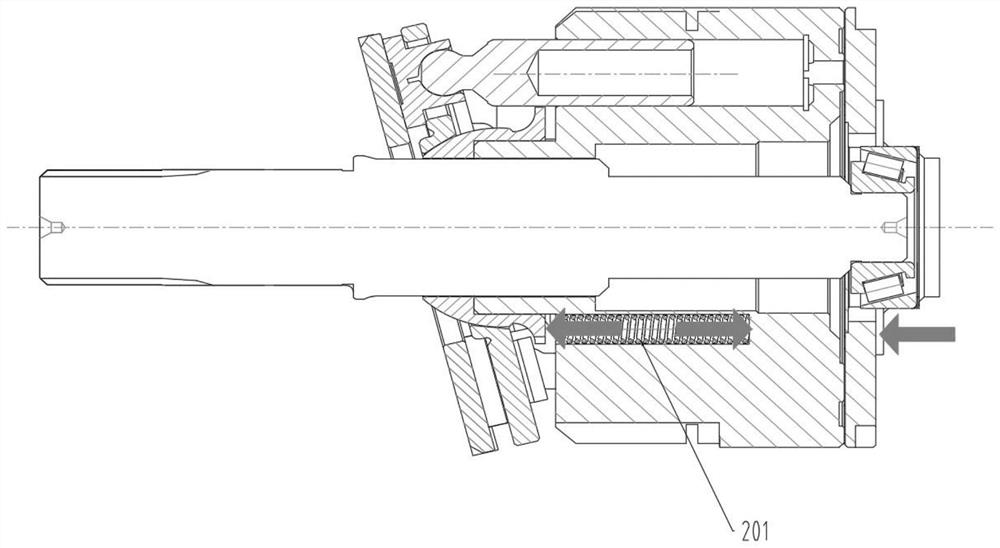

Simple energy-saving electric cooker

InactiveCN109805775AEasy to assembleSimple assembly structureCooking-vessel materialsCooking utensils shields/jacketsBiochemical engineeringThermal deformation

The invention provides an electric cooker which comprises a base and a support part connected with the base, and further comprises a protection layer arranged on the surface of the support part, and aconnecting part arranged between the base and the support part. The protection layer is arranged on the surface of the support part; an assembly structure is simple; and due to the design, the electric cooker is not prone to thermal deformation and mechanical deformation; and the electric cooker is simple to assemble and safe to use.

Owner:杜蒙

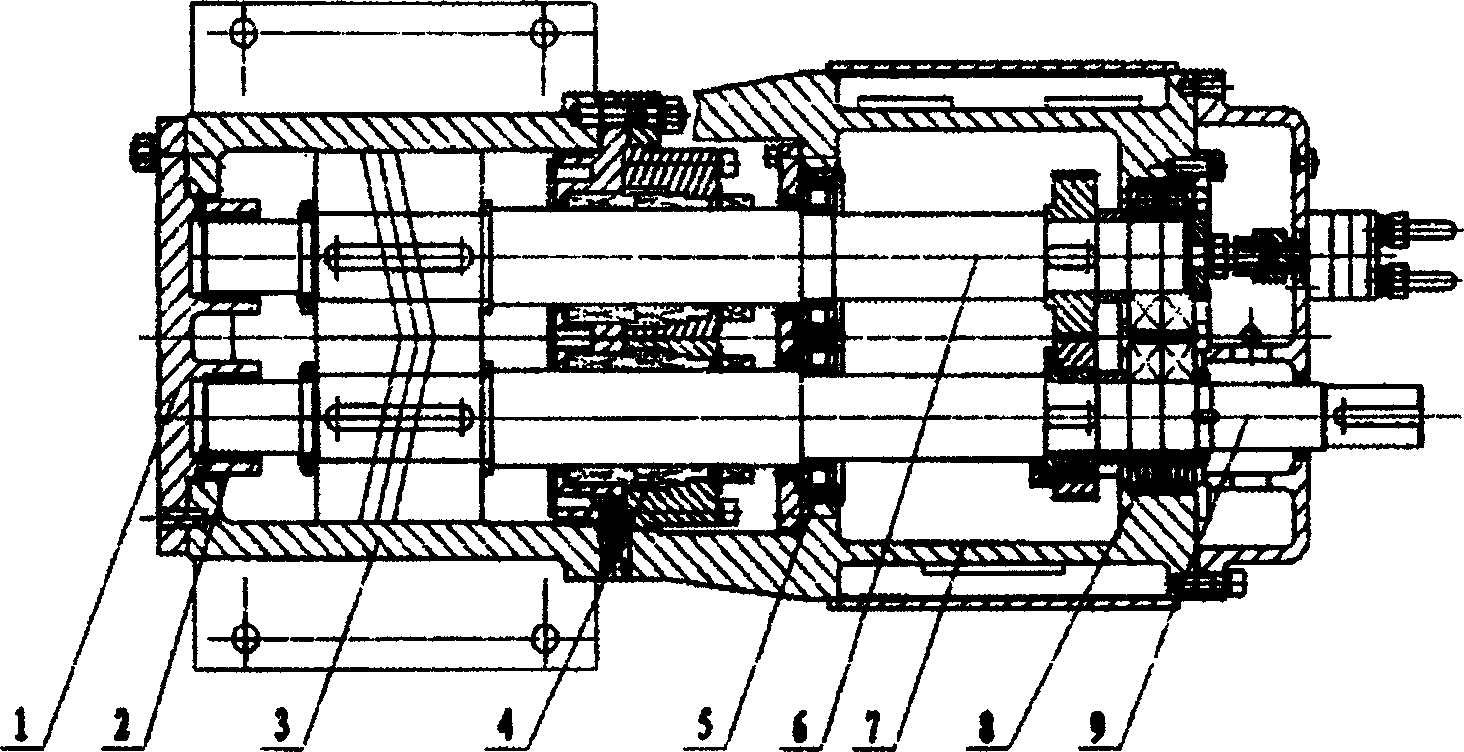

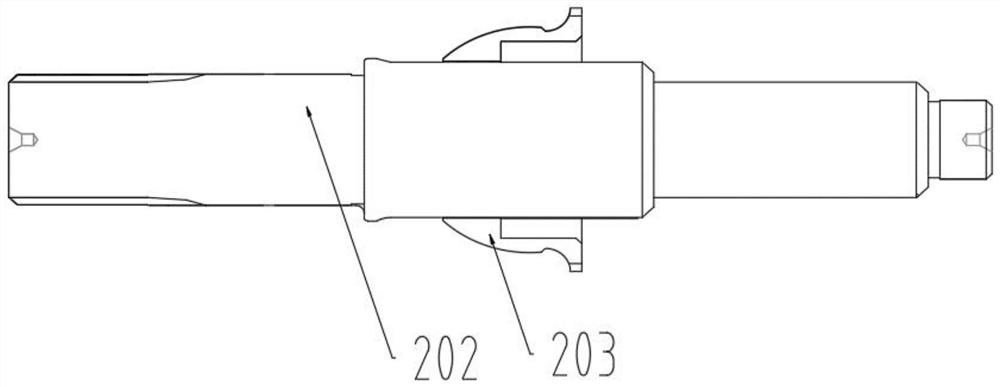

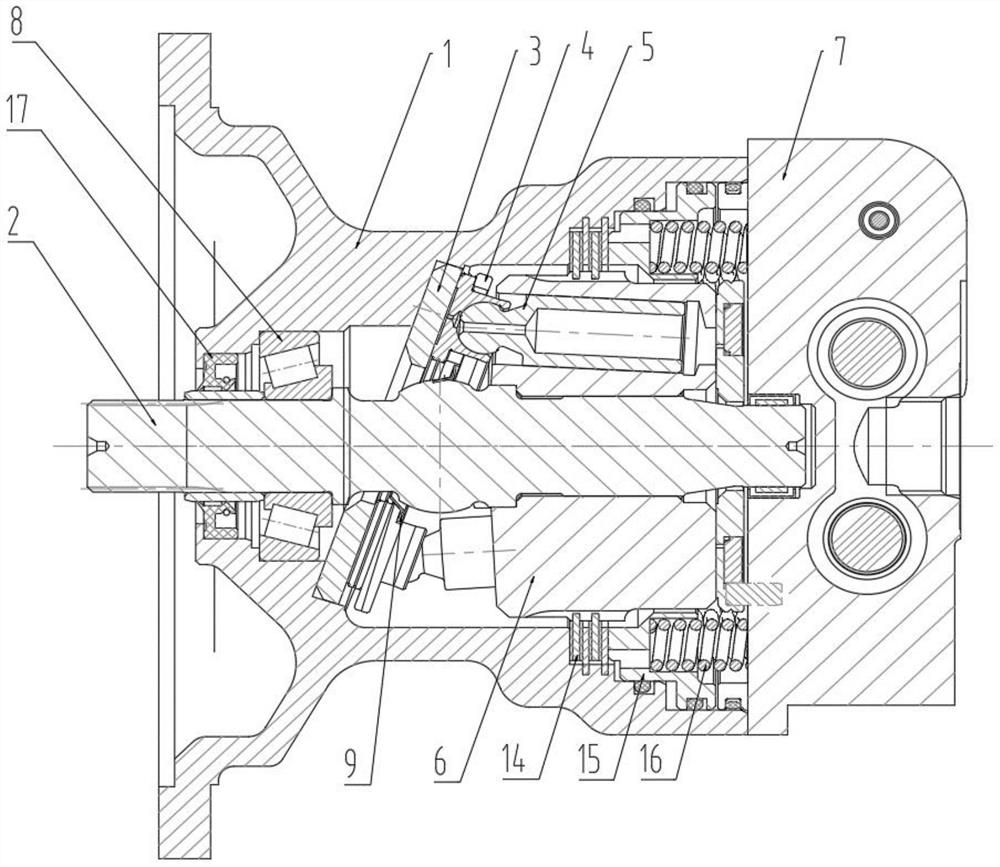

Hydraulic motor with integral output shaft

PendingCN112983730AReduce the impactNot easy to heat deformationReciprocating piston enginesEngineeringCylinder block

The invention discloses a hydraulic motor with an integral output shaft. The hydraulic motor comprises a shell, the integrated output shaft, a thrust plate, a retainer plate, a plunger, a cylinder body and an end cover, wherein the integrated output shaft is sequentially equipped with a front contact section, a spherical section, a middle contact section, a synchronous section and a rear contact section from front to back in the axial direction; the front contact section is rotatably connected to the front end of the shell through a front bearing; a special-shape spring is arranged on the spherical section in a sleeving manner, and the spherical section is elastically connected with the rear surface of the retainer plate through a special-shape spring; the middle contact section is a convex ring retaining shoulder and is resisted against the front end of the cylinder body; the synchronous section is arranged in the cylinder body and is connected with the cylinder body; the rear contact section penetrates through a flow distribution plate and is rotatably connected with the end cover through a rear bearing; and a floating piston ring is arranged at the front end of the end cover, and a corrugated spring is arranged between the floating piston ring and the end cover. According to the hydraulic motor with the integral output shaft disclosed by the invention, a ball joint structure of a ball joint type output shaft is eliminated, the influence of the coaxiality on the quality and the performance of products during processing of the products can be greatly reduced, the reliability is high, the structure is simple, the hydraulic motor is mounted and maintained more conveniently.

Owner:JIANGSU ZHENJI MACHINERY MFG

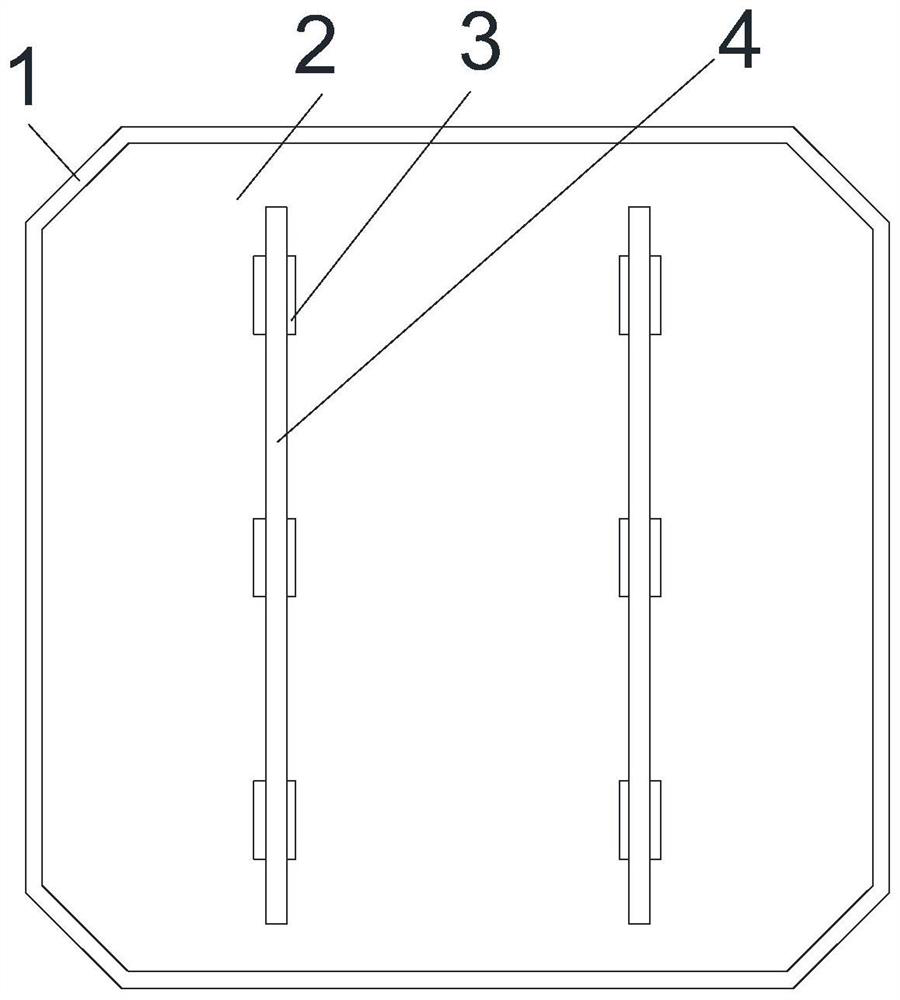

IBC photovoltaic battery module and welding process thereof

ActiveCN112768544AImproved resistance to twistingAbility to increase static pressureFinal product manufacturePhotovoltaic energy generationHeat resistanceEngineering

The invention provides an IBC photovoltaic battery module and a welding process thereof. The IBC photovoltaic battery module comprises a battery piece, an insulating resin layer, a plurality of solder paste layers and copper foil strips, wherein the insulating resin layer is arranged on the back surface of the battery piece; the plurality of solder paste layers are arranged on the surface of the insulating resin layer, and the plurality of solder paste layers are linearly arranged on the surface of the insulating resin layer at intervals; and the copper foil strips are arranged on the surfaces of the solder paste layers, the copper foil strips are arranged to be in a long strip shape, and the copper foil strips are connected with the solder paste layers on the same side in a welding mode. In the invention, the insulating resin layer and the solder paste layers are arranged on the back surface of the battery piece, and the solder paste layers are connected and connected in series through the copper foil strips, so that an interconnection strip is replaced, and the cost is reduced. Meanwhile, the generation of hidden cracks of the IBC battery piece is reduced by utilizing the good mechanical property and heat resistance of the insulating resin layer, and the assembly performance is more excellent.

Owner:锦州阳光能源有限公司

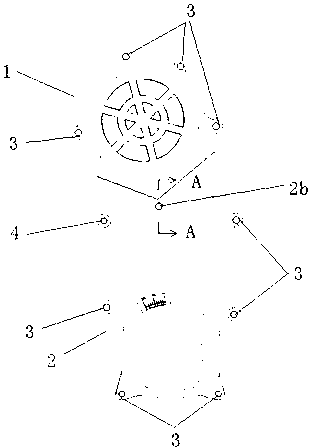

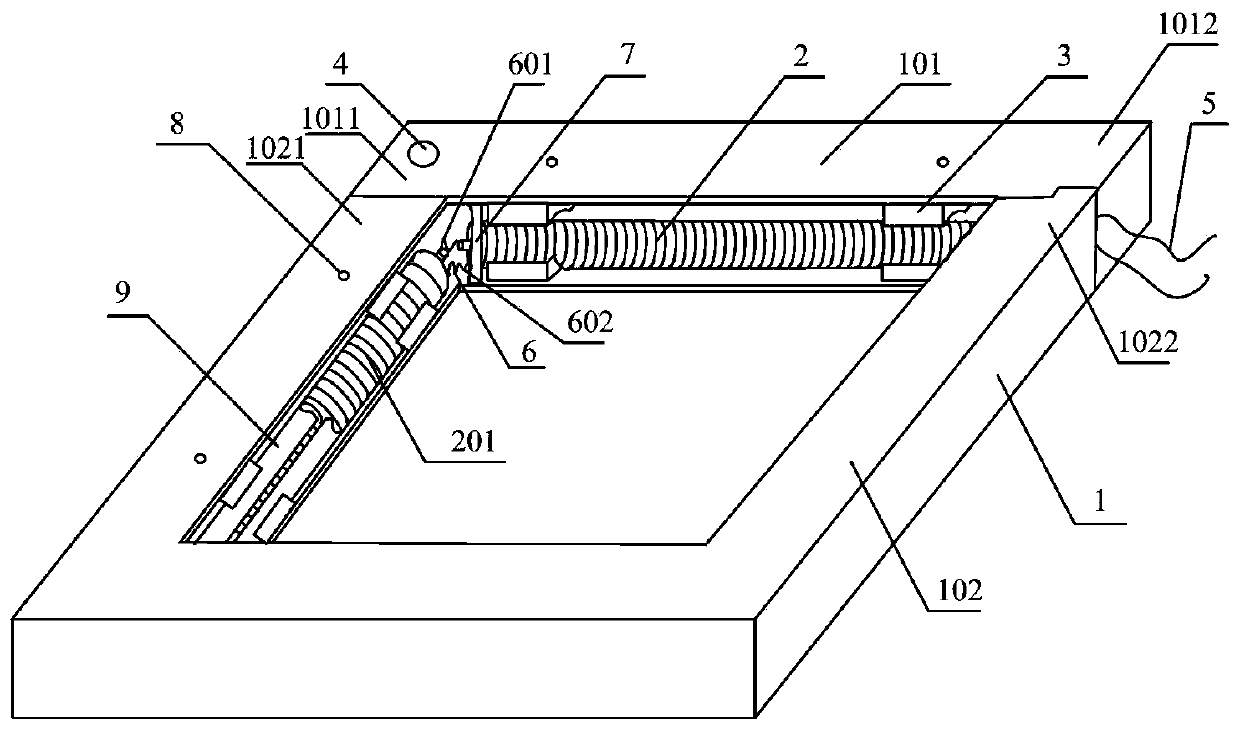

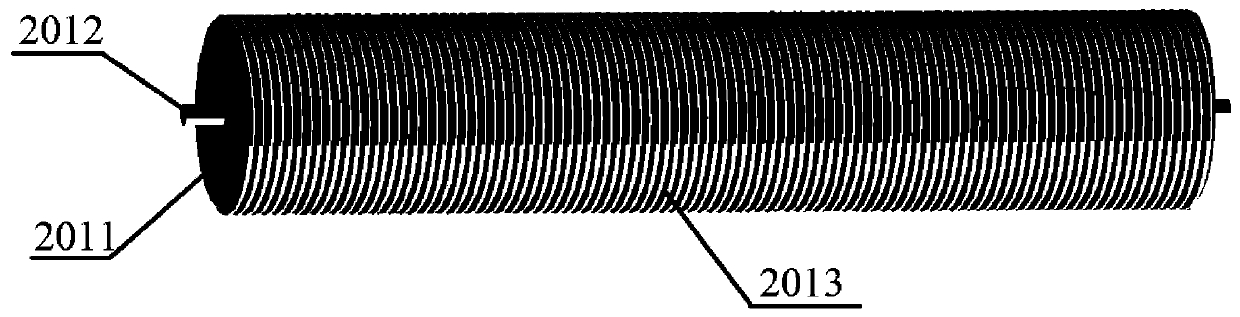

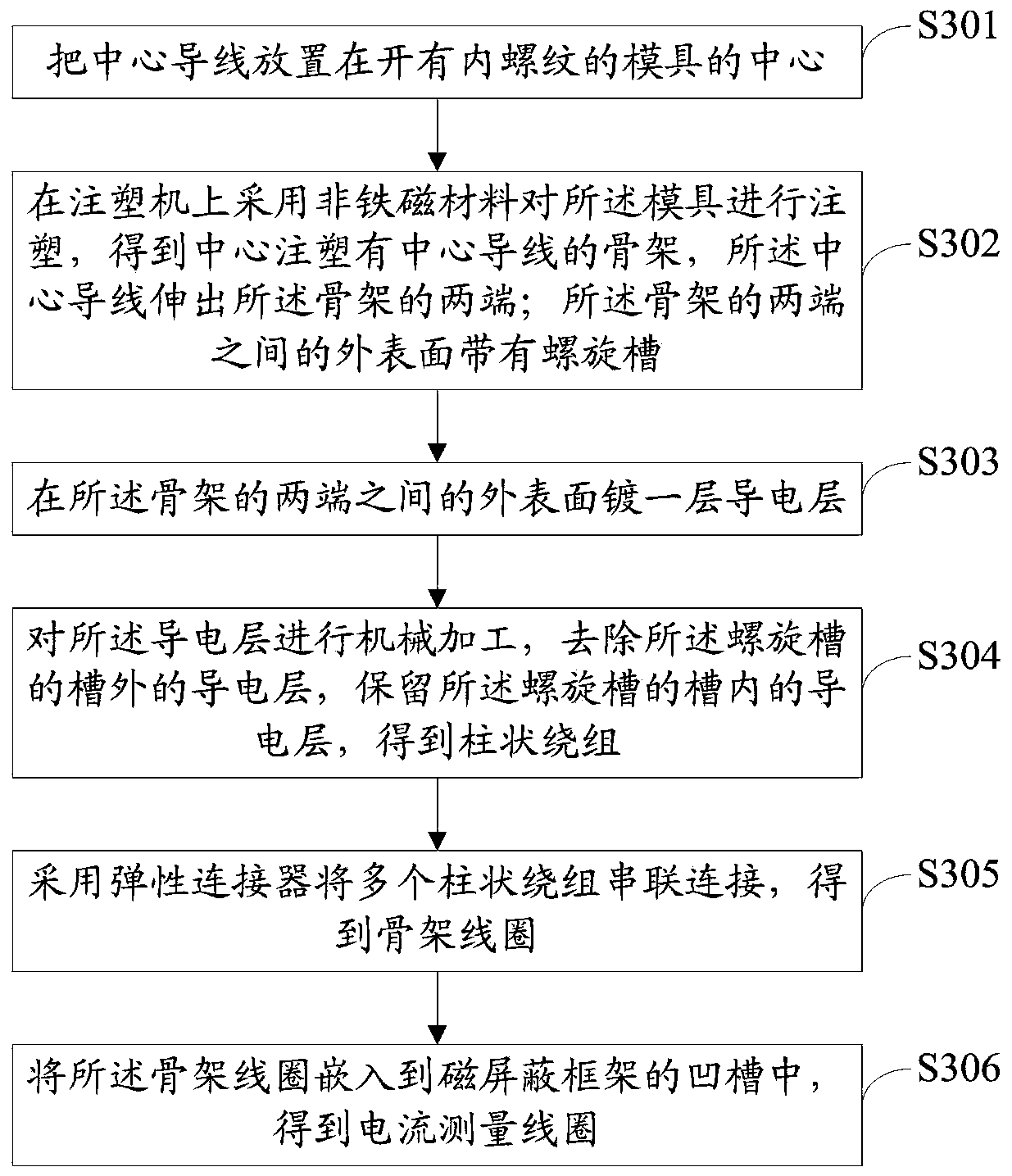

A current measuring coil and a manufacturing method of the current measuring coil

ActiveCN106932620BGuaranteed service lifeUniform mutual inductance coefficientManufacture of electrical instrumentsVoltage/current isolationEngineeringInjection molding process

The present invention discloses a current measuring coil, and a manufacturing method of the current measuring coil. The current measuring coil comprises a magnetic shielding frame, a framework coil and an insulated support block. The magnetic shielding frame is of a closed frame structure. The inner side of the magnetic shielding frame is provided with a groove. The insulated support block is embedded between the inner wall of the groove and the outer wall of the framework coil. The framework coil embedded in the insulated support block. The framework coil is formed through the series connection of a plurality of columnar windings. Each columnar winding comprises a framework, a center conductor and a conductive coil. The framework, made of non-ferromagnetic materials, is prepared through the injection molding process to be of a columnar structure. The center conductor is formed at the center of the framework through the injection molding process. The center conductor extends out of the two ends of the framework. The outer surface of the framework, between the two ends of the framework, is provided with a spiral groove. The conductive coil is plated inside the spiral groove. According to the technical scheme of the current measuring coil, and the manufacturing method of the current measuring coil, the consistency of the cross-sectional areas of windings can be ensured and the windings are uniformly distributed. The measurement accuracy is effective improved.

Owner:ZHENGZHOU WEIDA ELECTRONICS CO LTD +1

High strength direct cooling type bush of sugar cane press

InactiveCN1195071CIncrease cooling areaAvoid deformationPressesJuice extraction from sugarcaneEngineeringHigh intensity

Owner:王孝忠

High-heat-resistance degradable modified polystyrene foam packaging material and preparation method thereof

ActiveCN111763347AImprove hydrophilicityDisruption of regularityBio-packagingPolymer sciencePolystyrene particle

The invention relates to the field of packaging materials, and discloses a high-heat-resistance degradable modified polystyrene foam packaging material and a preparation method thereof. The foam packaging material is prepared from styrene, alkenyl graft modified starch and rosmarinic acid modified tetravinyl tetraphenyl-POSS as raw materials through the following steps: (1) mixing a dispersing agent with water, adding an initiator and styrene, uniformly dispersing, and reacting at 90-100 DEG C for 1-2 hours; (2) adding alkenyl graft modified starch and rosmarinic acid modified tetravinyl tetraphenyl-POSS, uniformly mixing, reacting for 4-6 hours at 100-120 DEG C, and drying to obtain modified polystyrene particles; and (3) foaming and curing the modified polystyrene particles to obtain themodified polystyrene foam packaging material. The foam packaging material provided by the invention has good degradability, heat resistance and oxidation resistance, can be used for packaging food with high temperature, is not easy to age, and has small decomposition pressure on the environment after being discarded.

Owner:安徽裕河新材料有限公司

Grinding roller of high-dispersion three-roller machine for conductive slurry production

InactiveCN106955764AImprove grinding and dispersing effectImprove grinding and dispersing efficiencyGrain treatmentsConductive pasteCooling effect

A grinding roller for a high-dispersion three-roller machine for the production of conductive paste proposed by the present invention includes a roller main body, a liquid inlet and outlet sleeve, a rotating end and a connecting plate. The liquid outlet and the liquid outlet are always connected with the cooling liquid channel, and the liquid inlet and outlet sleeves are rotatably connected with the liquid inlet and outlet shafts at the rotating end through the limit sleeve, and are sealed by the sealing ring in the sealing groove. The invention has a simple structure and a reasonable design. When the grinding roller When the cylinder rotates, the liquid inlet and outlet sleeves do not rotate accordingly, and the liquid inlet and outlet are always connected with the cooling liquid channel under the action of the liquid inlet slot and the liquid outlet slot. The sealing is good, the cooling liquid is not easy to leak, and the cooling The liquid channel adopts an S-shaped design, the delivery of the cooling liquid is smoother, and the delivery area of the cooling liquid is relatively comprehensive and accurate. The roller cools down quickly and is not prone to thermal deformation. Furthermore, when grinding and dispersing the conductive paste, it can improve the grinding and dispersing effect of the conductive paste, prolong the continuous working time of the three-roller machine, and improve the grinding and dispersing efficiency of the conductive paste.

Owner:江苏昱星科技股份有限公司

Thermal fatigue testing machine

The invention provides a thermal fatigue testing machine, which is characterized in that: the testing machine includes a support and a thermal fatigue sample; the support is a pillar structure with flanges on the upper and lower sides, and a cooling channel for the support is provided in the center of the support. The upper part of the thermal fatigue sample is clamped at the upper flange of the support and the lower part is clamped at the lower flange, and an induction heating coil is wound on the outer wall of the thermal fatigue sample. The invention has reasonable structure, scientific operation and obvious effect, and is suitable for popularization and application in the field of thermal fatigue test.

Owner:SHENYANG POLYTECHNIC UNIV

engine timing cover

ActiveCN103161602BReduce workloadReduce maintenance costsCasingsValve arrangementsEngineeringCamshaft

The invention relates to a correct timing cover piece of a motor. The cover piece is characterized in that an installation support lug and a water pump installation support lug are installed on the edge of the cover piece, the cover piece is formed by an upper correct timing cover piece and a lower correct timing cover piece in an overlap joint mode, a first overlap-joint step is installed on the overlap-joint edge of the upper correct timing cover piece and a second overlap-joint step is installed on the overlap-joint edge of the lower correct timing cover piece. The upper correct timing cover piece and the lower correct timing cover piece are connected in the overlap joint mode through the first overlap-joint step and the second overlap-joint stage. The first overlap-joint stage is provided with a first water pump installation hole, the second overlap-joint stage is provided with a second water pump installation hole, and after the upper correct timing cover piece and the lower correct timing cover piece are connected in the overlap-joint mode, the first water pump installation hole and the second water pump installation hole are overlapped. The water pump installation support lug is located on the lower correct timing cover piece, a length ratio of the upper correct timing shroud cover piece and the lower correct timing cover piece is 2-4: 6-8. The correct timing cover piece of the motor has the advantages of enabling a correct timing adjustment of the motor and maintaining of a camshaft gear train to be convenient.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Cooled glass gathering machine

InactiveCN103387327ARealize circulating water coolingImprove cooling effectHalogen/halogen-acidsInlet channelCooling effect

The invention discloses a cooled glass gathering machine which comprises a fixing seat, a rotary disc connected to the fixing seat, and a frame connected to the rotary disc, wherein a rocker arm capable of rotating is arranged on the frame; a rod seat is hinged to the rocker arm; a gathering rod is rotationally connected to the rod seat and comprises a gathering rod body; the gathering rod body consists of a conical rod section and a straight rod section; a gathering ball is detachably connected to the front end of the conical rod section; the straight rod section comprises a spindle; more than one water inlet spiral groove is formed in the outer surface of the spindle; a shell, which is in a sealing fit relationship with the outer surface of the spindle, is tightly sleeved outside the spindle; the more than one water inlet spiral groove is enclosed to form more than one water inlet channel through the shell; a water outlet hole is formed in the spindle; the water inlet channel is communicated with the front end of the water outlet hole; a water inlet hole communicated with the water inlet channel is formed in the rear end section of the shell. The gathering rod of the machine has the advantages of having a good cooling effect and being unlikely to deform when being heated, and thus the service life of the gathering rod can be effectively prolonged.

Owner:高密圣泰机电科技有限公司

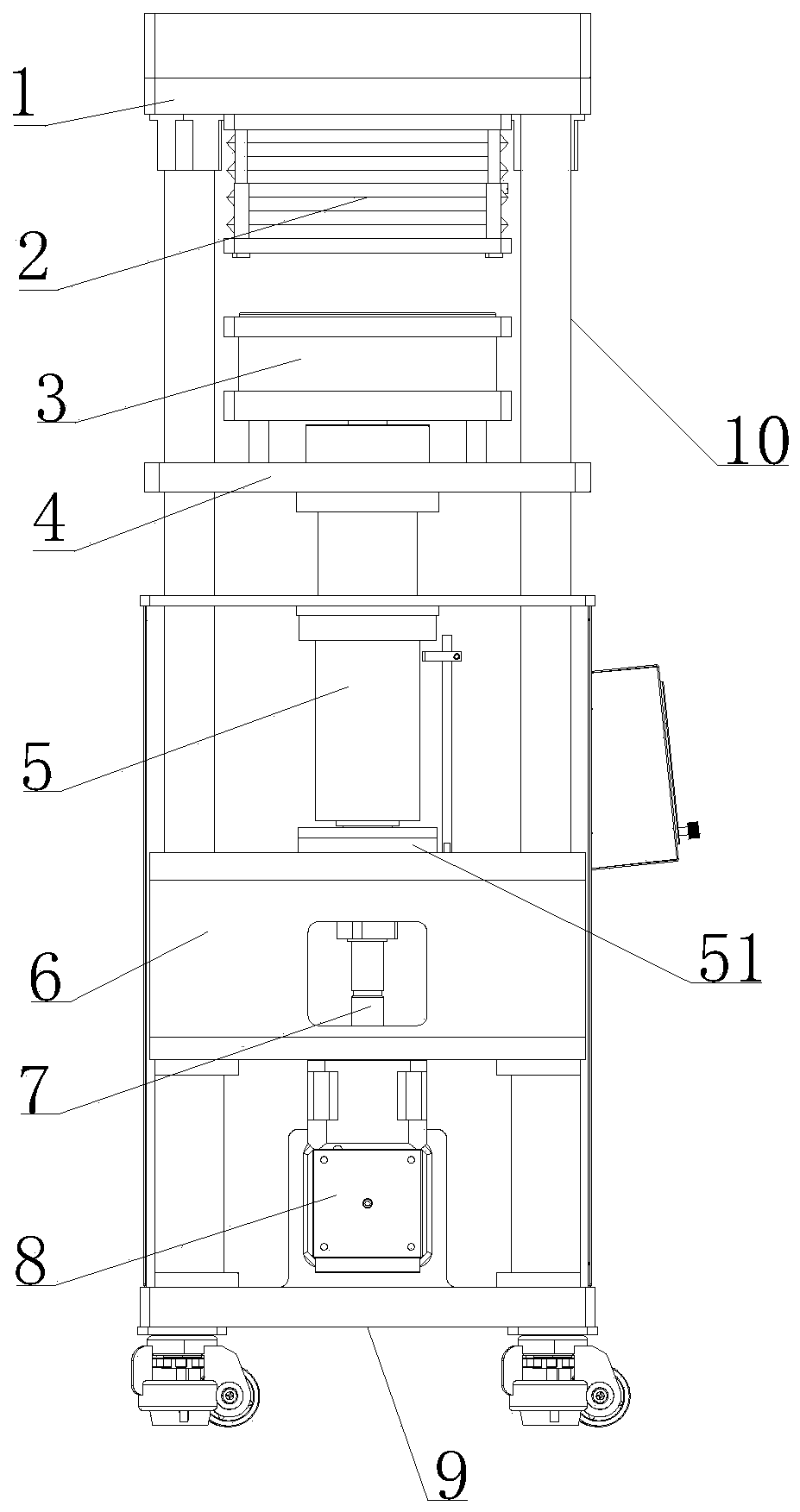

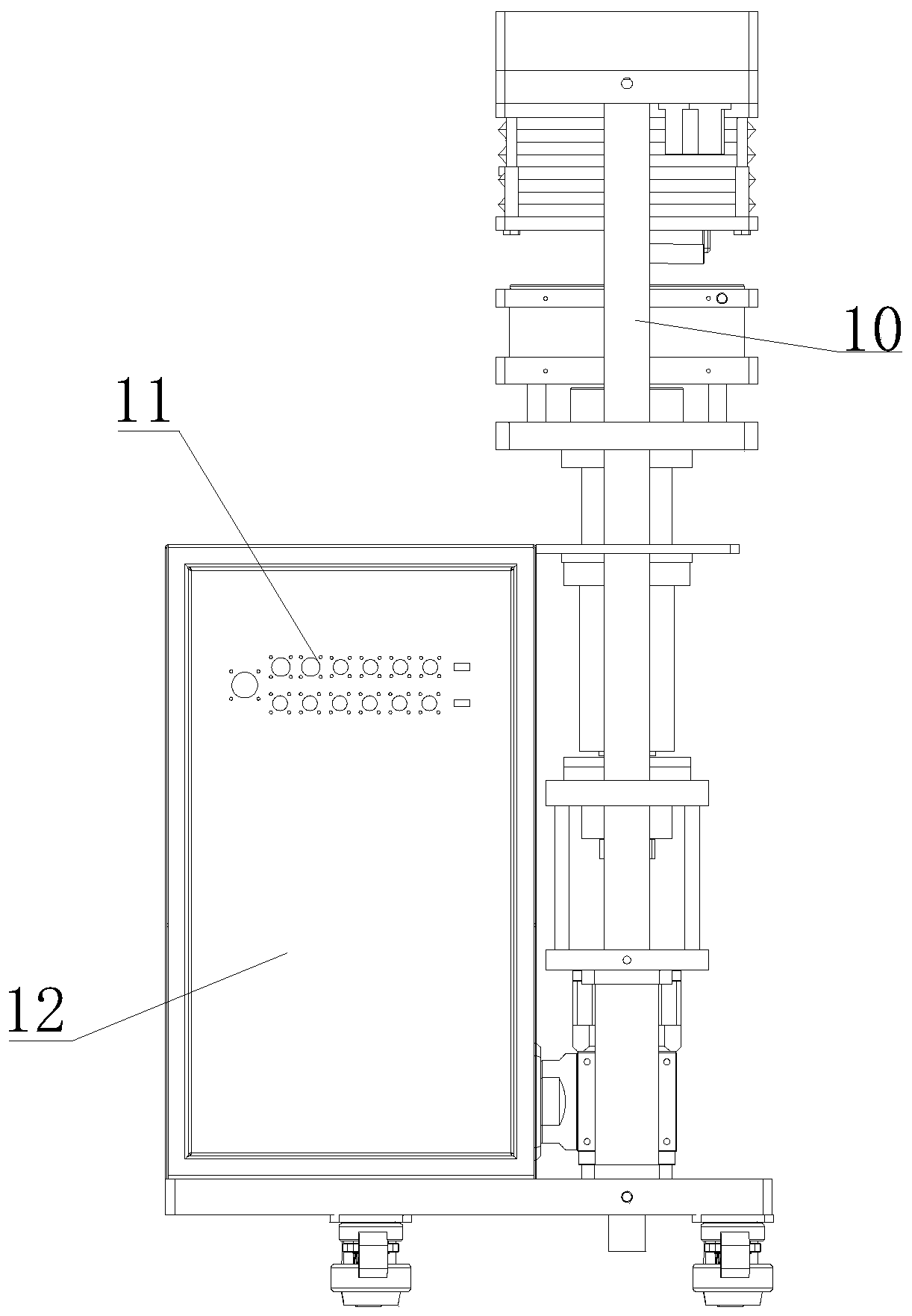

High-temperature vacuum tabletting equipment for polymer

The invention discloses a high-temperature vacuum tabletting equipment for polymer. The high-temperature vacuum tabletting equipment comprises a top plate, a lower mold cushion plate, a screw rod sleeve, a screw rod, a motor, a vacuum pump and a heating rod, the top plate is connected with a bottom plate through a plurality of sets of tiebars, an upper mold heat insulation plate is arranged on thelower end surface of the top plate, an upper mold is arranged on the lower end surface of the upper mold heat insulation plate, an upper mold cooling channel is arranged on the upper mold, an elasticcorrugated pipe is arranged on each of the outer sides of the upper mold heat insulation plate and the upper mold in a sleeving mode, the screw rod sleeve is connected with the screw rod to form a synchronous rotation structure so as to drive the lower mold cushion plate to move, the screw rod is rotatably connected with a mounting bracket arranged on each tiebar through a screw rod fixing base,the screw rod is connected with a speed reducer through a coupling, a lower mold cooling channel and a pressure sensor are arranged on a lower mold arranged on the lower mold cushion plate, a sealed cavity is formed among the lower mold, the elastic corrugated pipes and the top plate, and a vacuumizing hole for connecting the air inlet end of the vacuum pump is arranged on the cavity. According tothe high-temperature vacuum tabletting equipment, heating of the vacuum environment for raw materials to be processed can be improved, the heating temperature is high, and 10 tons of pressure can beprovided for meeting the needs of tabletting.

Owner:ZHENGZHOU CRAFTSMAN MACHINERY EQUIP CO LTD

Outdoor steel storage tank and manufacturing method thereof

InactiveCN102020043AReduce weightNot easy to heat deformationHot-dipping/immersion processesRigid containersThermal deformationZinc

The invention discloses an outdoor steel storage tank and a manufacturing method thereof. One problem of the conventional outdoor steel storage tank is that the hot dip zinc processing is required, wherein the thickness of the steel plates of the outdoor steel storage tank can be increased or the reinforcing plates can be welded on the steel plates in order to prevent the thermal deformation caused by the residual stress of the steel plates. In the outdoor steel storage tank provided in the invention, the flat parts of the steel plates can be stamped into concave parts or protruding parts (the protruding flanges), thereafter the steel plates can be combined together into a box, then the hot dip zinc processing can be finished.

Owner:SHINKO SEISAKUSHO LTD

An improved flat rolling method and device

ActiveCN105058229BImprove uniformityNot prone to thermal deformationBurnishing machinesMachined surfaceThermal deformation

Disclosed is a modified planar rolling method. The planar rolling method comprises the steps that a workpiece is attached under a planet wheel and makes contact with balls arranged on an upper grinding disk; the workpiece applies load to the planet wheel; the upper grinding disk tends to move downwards under the action of the rolling load; when the rolling load exceeds the pretightening force of springs, the upper grinding disk moves downwards continuously along bolts and the pretightening force also increases gradually until the pretightening force is in balance with the rolling load; the springs in a compression state are capable of providing restoring force and self-adaptively adjusting the contact state of the balls and the surface of the workpiece; the workpiece is in a rotation and a revolution along with the planet wheel; and the balls on the upper grinding disk roll the surface of the workpiece again and again and even rolling tracks are left on the surface. The invention further provides a rolling grinding device for achieving the planar rolling method. The modified planar rolling method is good in uniformity and relatively high in machining precision; the thermal deformation of the machined surface is not prone to occurring.

Owner:湖州优研知识产权服务有限公司

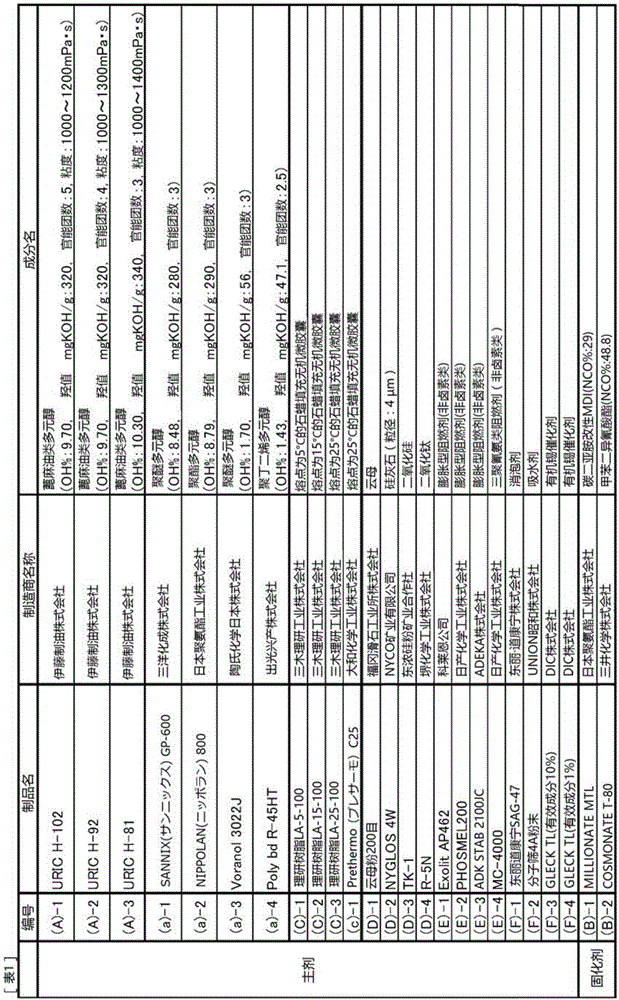

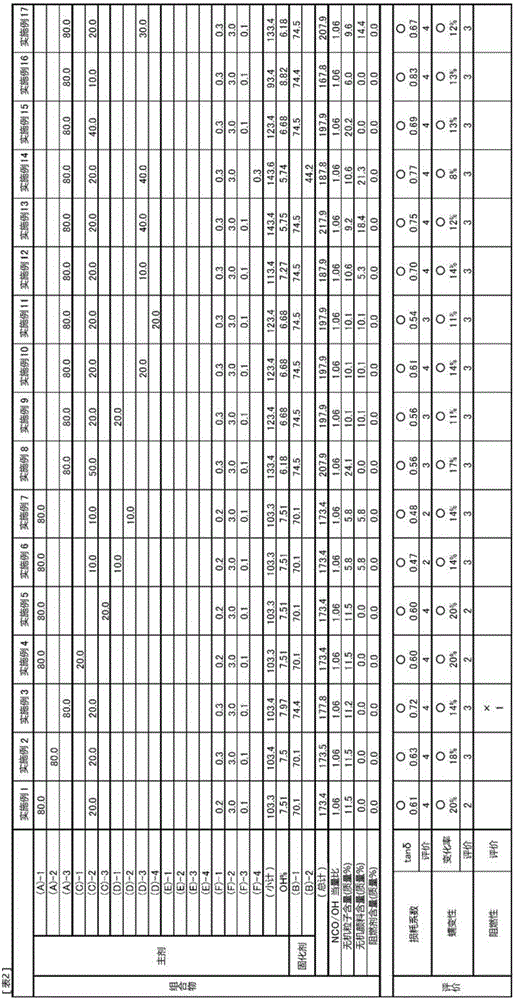

Vibration-damping urethane resin composition, vibration-damping molded urethane resin object, and method for forming said molded object

ActiveCN106795265AImprove creep resistanceLarge loss factorNon-rotating vibration suppressionHeat-exchange elementsPolyolInorganic particle

The present invention relates to a vibration-damping urethane resin composition, a vibration-damping molded urethane resin object, and a method for forming the molded object, the vibration-damping urethane resin composition comprising a castor-oil-derived polyol (A), an isocyanate (B), and inorganic particles (C) which contain a phase-change substance therein.

Owner:CHUGOKU MARINE PAINTS

Process for producing sealing film, and sealing film

ActiveCN103222084BNot prone to short circuitImprove joint strengthSynthetic resin layered productsDouble layer capacitorsMolten statePolyolefin

Owner:FUJIMORI KOGYO CO LTD

Glass gathering machine

InactiveCN103395970AExtended service lifeRealize circulating water coolingGlass making apparatusRocker armThermal deformation

The invention discloses a glass gathering machine, comprising a fixed seat, a rotary disk connected to the fixed seat and a rack connected to the rotary disk, wherein the rack is provided with a rocker; the rocker is hinged with a rod seat; the rod seat is connected with a gathering rod; the gathering rod comprises a gathering rod body which is composed of a conical rod section and a straight rod section; a gathering ball is connected to the front end of the conical rod section; the straight rod section comprises a core shaft; the outer surface of the core shaft is provided with a plurality of circular grooves; a shaft section between two adjacent circular grooves is a communication section; the communication section is provided with a communication groove communicating the two adjacent circular grooves; a shell is tightly sleeved on the core shaft; the shell encloses the circular grooves to a plurality of circular water inlet channels and encloses the communication groove to a communication water channel; a water outlet is disposed in the core shaft; the forefront end of the circular water inlet channel is communicated with the water outlet; and the shell is provided with a water inlet communicated with the rearmost circular water inlet channel. The gathering rod of the glass gathering machine has a good cooling effect and cannot generate thermal deformation easily, and can effectively prolong the service life of the gathering rod.

Owner:山东圣泰机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com