High temperature screw pump

A screw pump, high temperature technology, applied in the direction of pumps, rotary piston pumps, rotary piston machinery, etc., can solve problems such as shaft holding, mechanical seal leakage on the pump end face, inconvenient use, pump failure to operate normally, etc., to overcome maintenance work A large amount of effect

Active Publication Date: 2005-04-06

CHINA PETROLEUM & CHEM CORP +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the pump body of the general twin-screw pump adopts a double-layer welded structure and the pipe wall is thin, it is prone to thermal deformation due to the influence of the high temperature environment and the installation pipeline, resulting in shaft holding, pump end face and mechanical seal leakage, making the pump unable to operate normally; , the pump body itself has a support form. Due to thermal expansion and contraction, the pump body grows taller in the hot state, and returns to its original position in the cold state, causing the pump and the motor to be re-aligned in the hot state, and in the cold state. In the state, the connecting bolts of the coupling must be removed, which brings great inconvenience to the use

Some domestic units have adopted imported pumps, but they still cannot solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

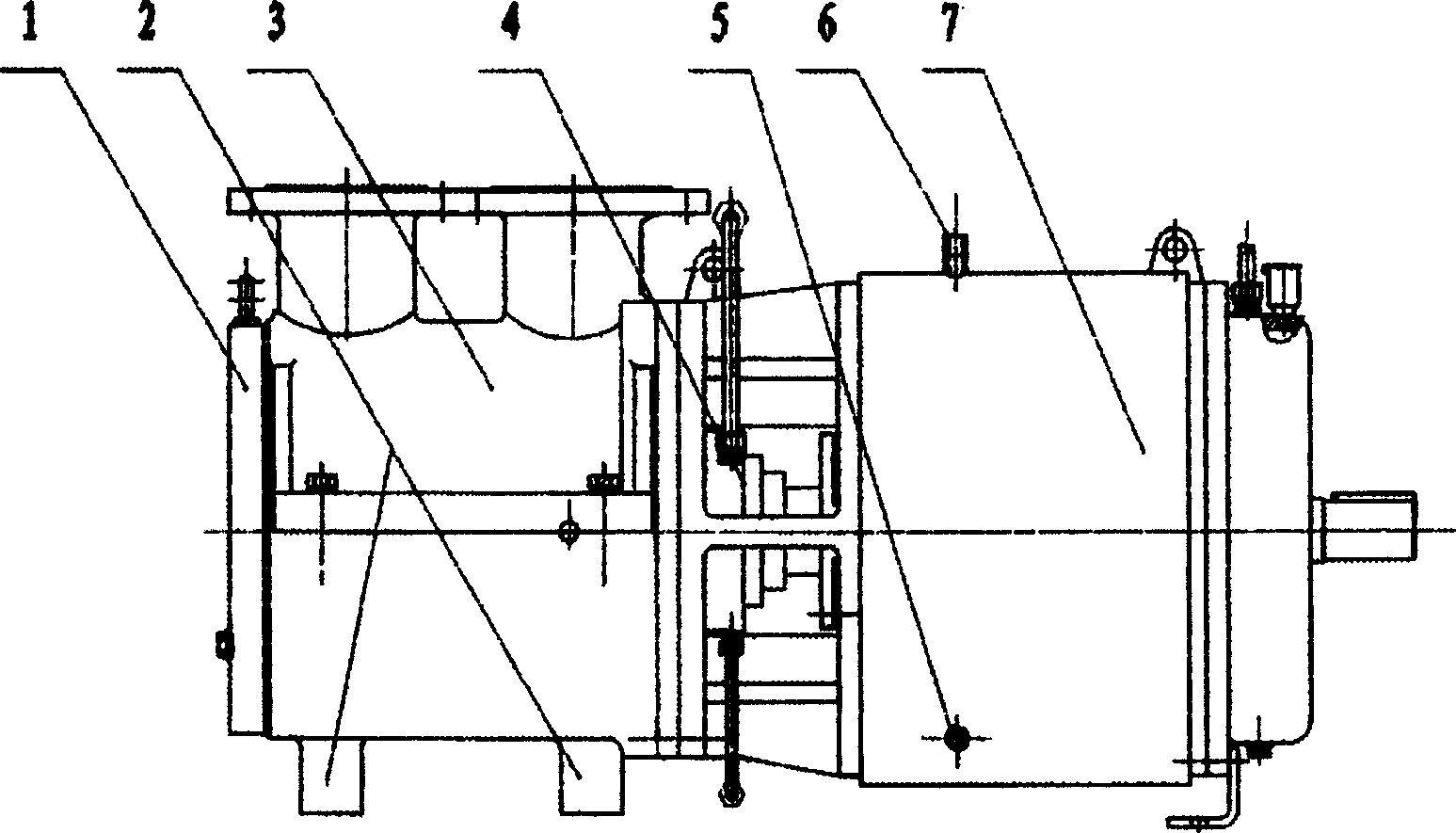

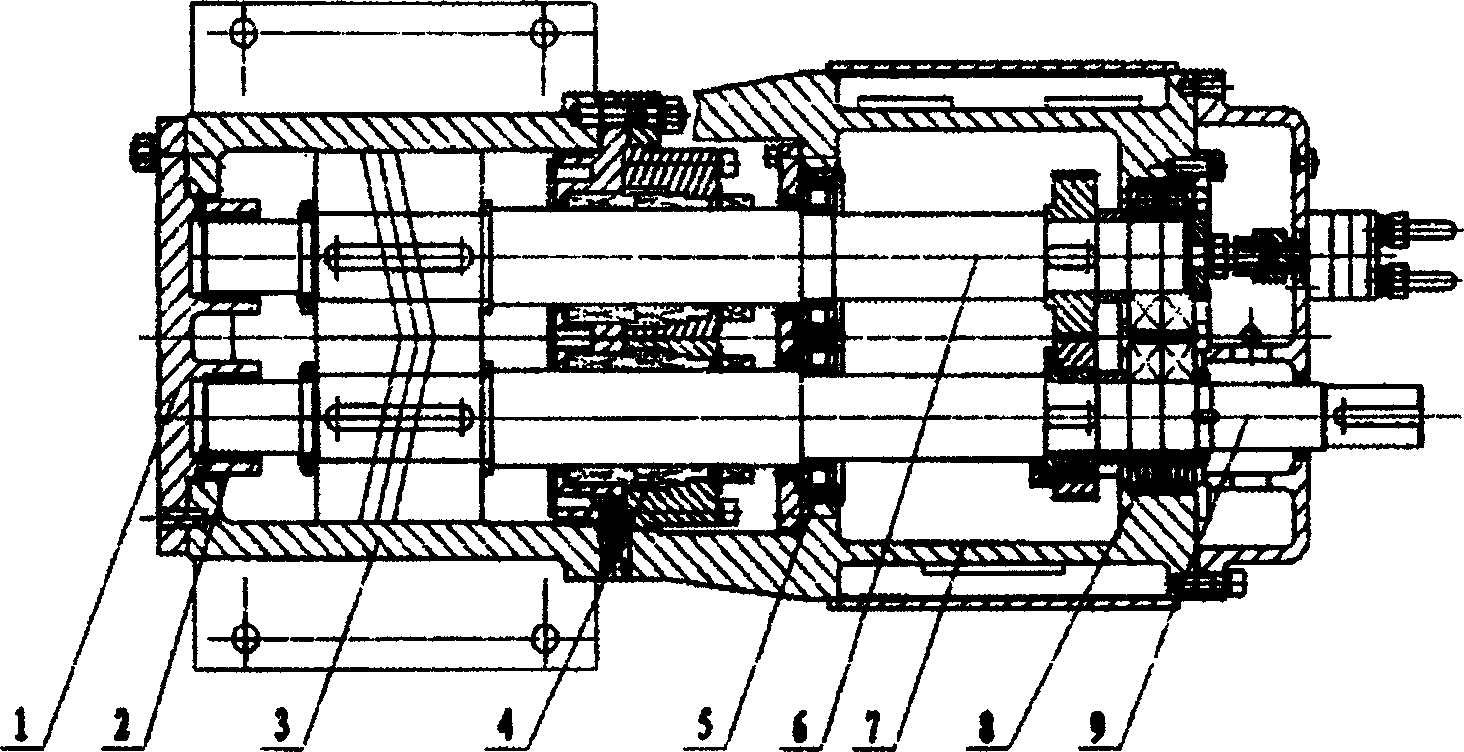

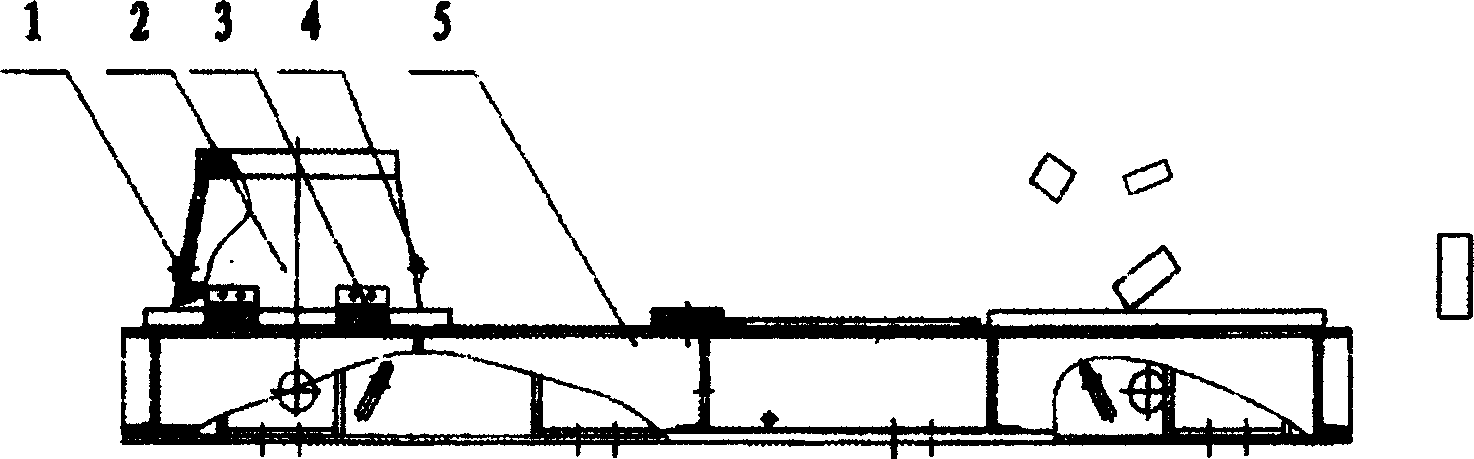

The invention involves a kind to be possible completely to substitute the petroleum chemical industry enterprise to refine oil in the installment centrifugal pump, the reciprocating pump or imports the screw rod to pump, and has thermostablly may reach 450deg.C, the performance stably, safe is reliable, the economical highly effective high temperature screw rod pumps. It both does not have the centrifugal pump to pump out the phenomenon, and has overcome the reciprocating pump service work load in a big way, overhaul period long characteristic, and the thorough settlement tradition double screw rod has pumped when transports above 300deg.C the high temperature medium the pump body is easy to appear the thermal deformation, causes to pump holds the axis, pumps the end surface and the mechanical seal divulges as well as pumps the association with the electricity association when the thermal state must readjust to the medium a series of questions. Its unique feature is: 1. The pump body uses opens the type structure, by foundation strut seat stay, but the bearing seat also is shoulders through the pump body, like this guaranteed has pumped cannot interfere with the normal work under the high temperature operating mode as a result of the pipeline thermal deformation; 2. Uses the collection attire type bearing gear structure, the bearing riggers band entire package water cooling, causes the bearing gear not the high temperature environment influence; 3. The host, all uses three struts localizations from the moving axis and the wing nut. When pumps suitablly uses in the higher working pressure.

Description

technical field The invention relates to a screw pump with high temperature resistance (transmission medium temperature can reach up to 450° C.), stable performance, safety, reliability and high efficiency. Background technique The high temperature oil pump is the key equipment of the petrochemical plant in petrochemical enterprises, and its normal operation is directly related to the normal operation and economic benefits of the petrochemical plant. At present, high-temperature oil pumps at home and abroad generally use centrifugal pumps and reciprocating pumps. However, deoiled asphalt is easy to foam at 280-360 ℃, and the use of centrifugal pumps will cause evacuation, which will damage the pump itself, which cannot guarantee the long-term operation of the pump; and the use of reciprocating pumps, although the evacuation phenomenon is avoided, but the reciprocating pump has There are disadvantages such as large maintenance workload and long maint...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C2/16

Inventor 高金初郑鸿伟赵育基夏军汤小明赵全根王路军易拥军熊露平唐竑

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com