Process for producing sealing film, and sealing film

A manufacturing method and sealing film technology, applied in sealing materials, chemical instruments and methods, mixing boxes/housing/packaging, etc., can solve problems such as sealing film melting and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

[0136] Add resin A and resin B to the hopper of the extruder at the blending ratio shown in Table 1, and extrude it while modifying it to resin C at the extrusion temperature shown in Table 1, and co-extrude at T Examples 1 to 15 of the sealing film 1 were casted and laminated with the resin D extruded from another extruder in the die head.

[0137] In the example in which three layers are written in the layer configuration column of Table 1, resin E was further extruded from another extruder during coextrusion casting to perform coextrusion lamination. Furthermore, in the example where 3 parts are written in the column of coloring agent in Table 1, 3 parts by weight of a PP-based pigment masterbatch was added when preparing resin A and resin B.

[0138] The extrusion temperatures of resin D and resin E were both set to 240°C.

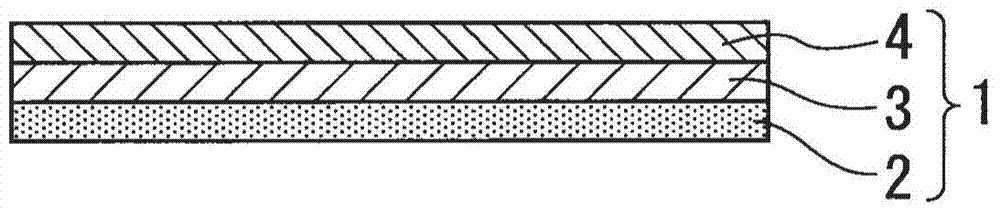

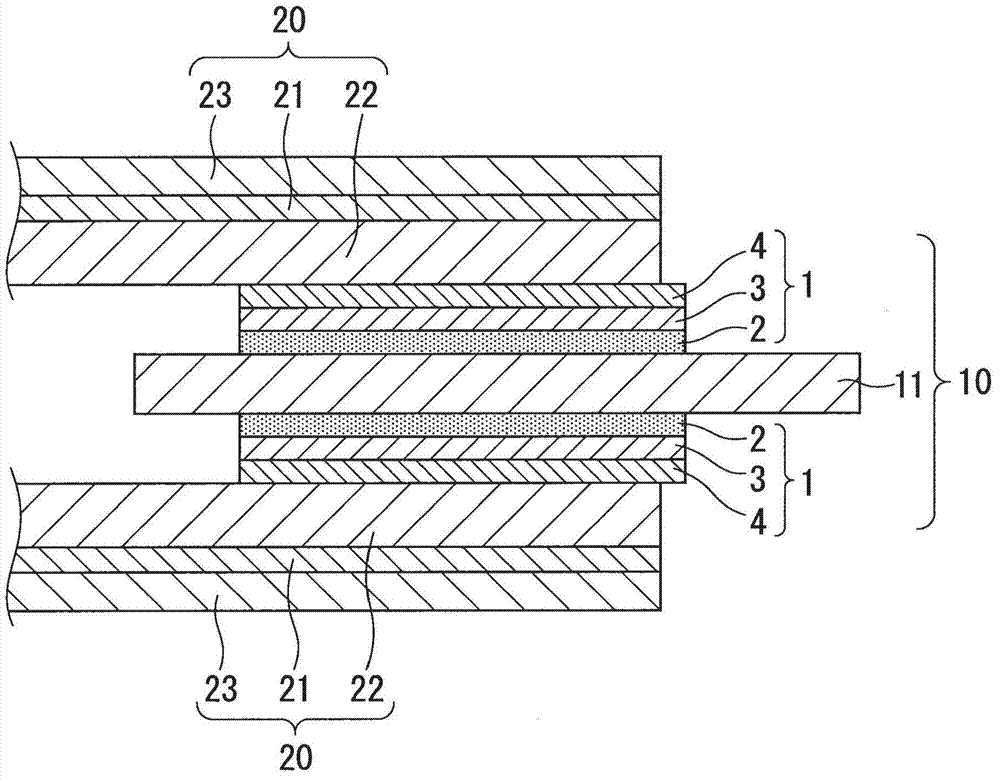

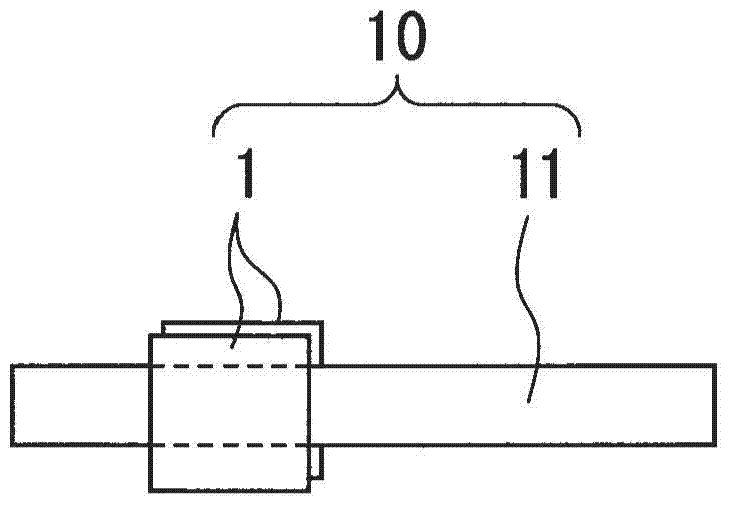

[0139] In the above-mentioned manner, a laminated film with a double-layer structure consisting of the electrode bonding layer 2 of 40 μm and the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com