Outdoor steel storage tank and manufacturing method thereof

A manufacturing method and storage box technology, applied to containers, coatings, rigid containers, etc., can solve the problems of reducing the weight of outdoor steel storage boxes, increasing the manufacturing time and cost of outdoor steel storage boxes, and achieving weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] [Appearance and functions of steel storage boxes for outdoor use]

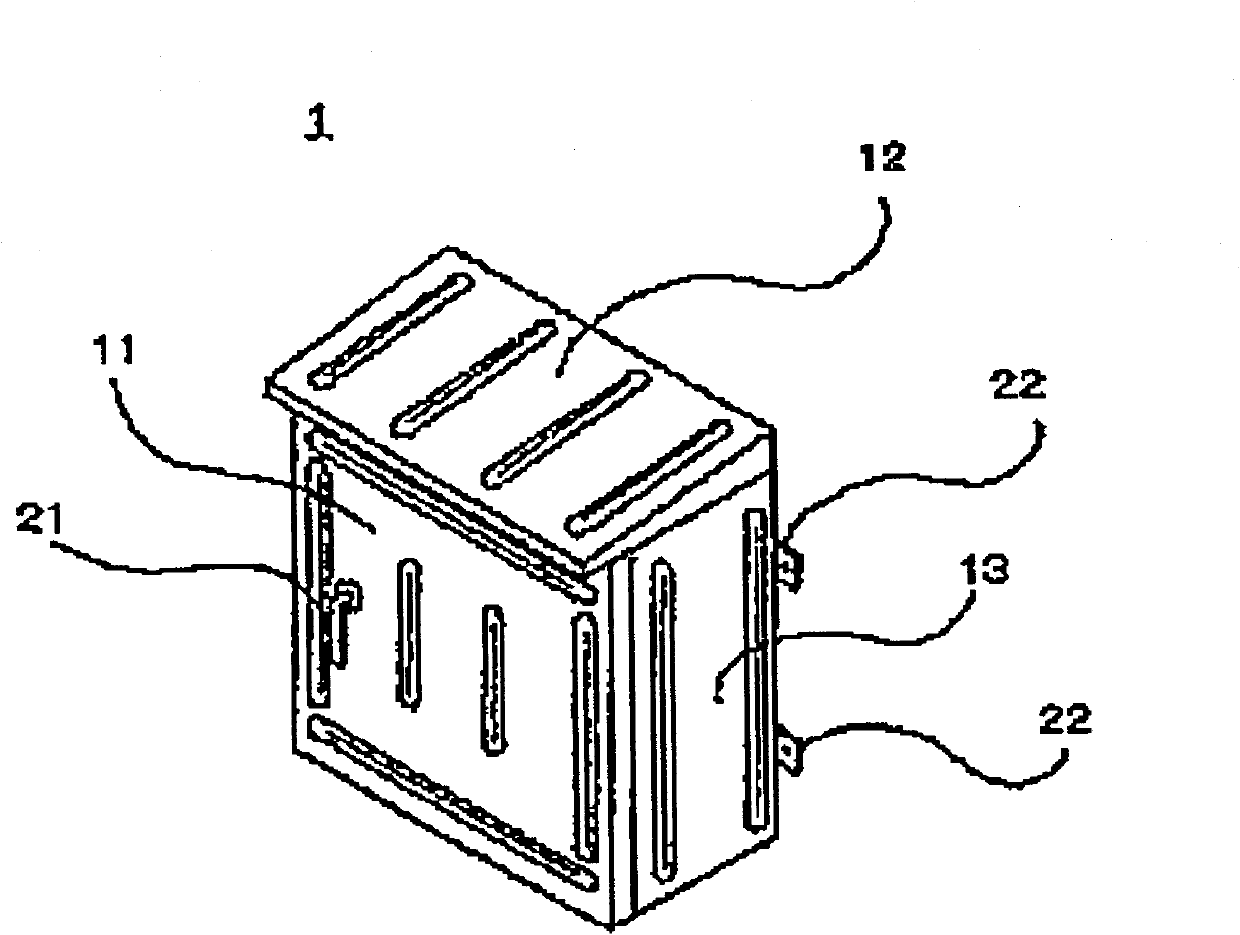

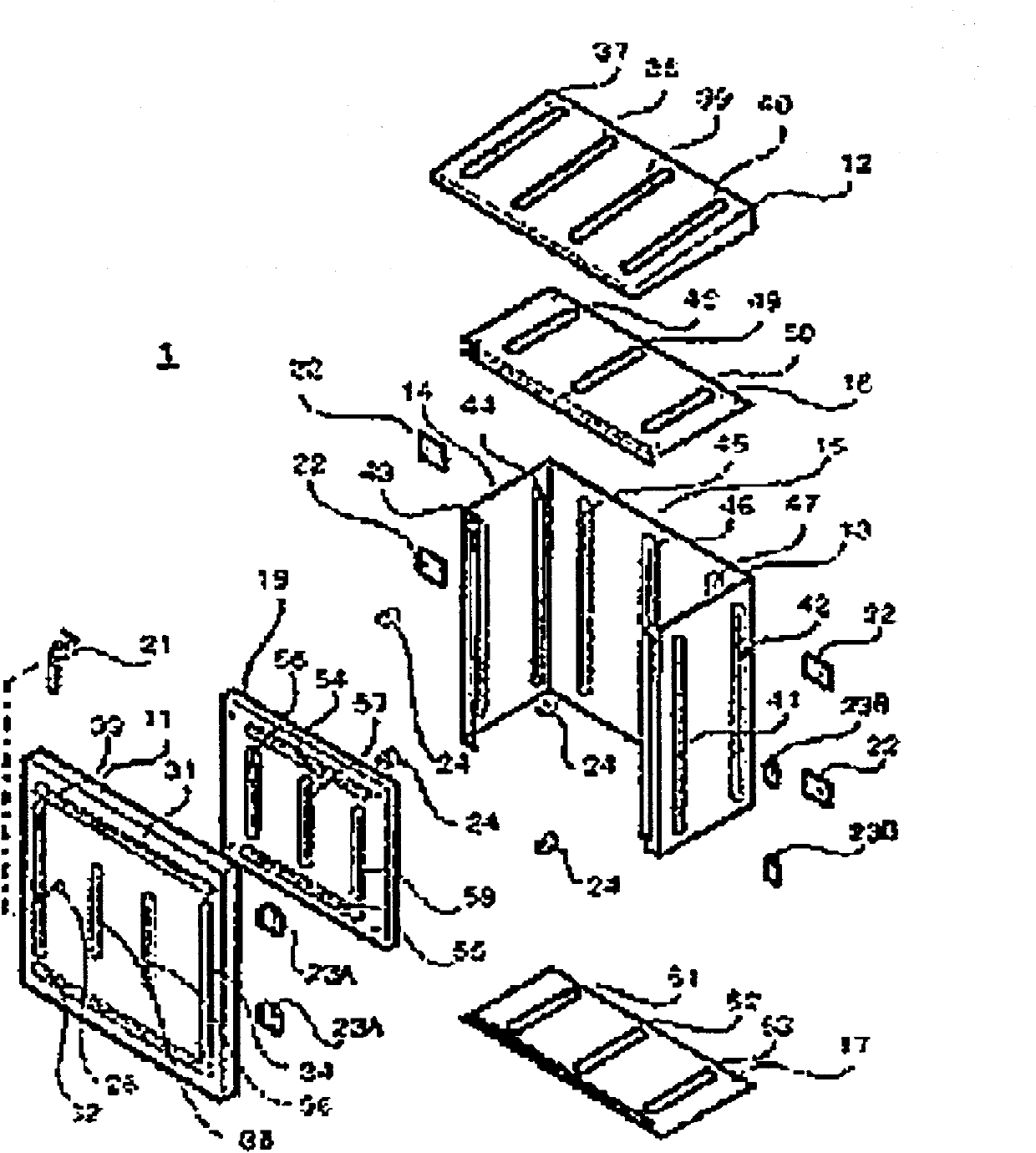

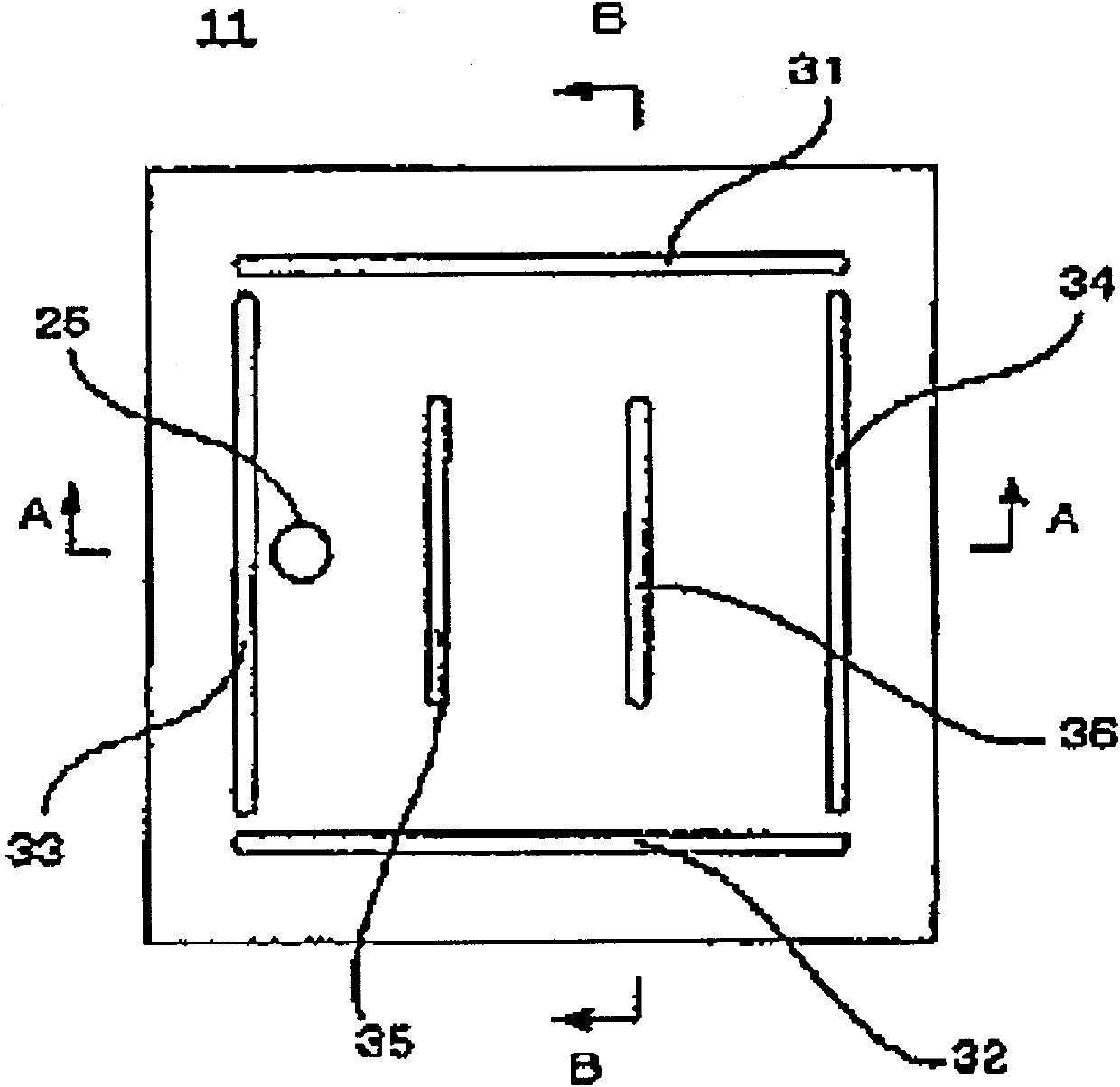

[0057] figure 1 The shown outdoor steel storage box 1 is generally in the shape of a cuboid, and its dimensions are about 400 mm wide, 440 mm high, and 180 mm deep. There is a door 11 on the front side, when the lever handle 21 mounted on the door 11 is rotated 90 degrees counterclockwise, the lock plate (not shown) inside the door 11 is rotated in conjunction with the lever handle 21, and the fixing of the door 11 is released, which can Open door 11.

[0058] When the door 11 is opened, a storage space surrounded by steel plates on five sides is provided inside the outdoor steel storage box 1 . The storage space is a space slightly smaller than the external dimensions. The purpose of this embodiment is to install the switchboard, control panel, operating machine and other storage objects in the outdoor steel storage box 1 by screws or the like in the internal storage space. On the mounting plate (desc...

Embodiment 2

[0103] With regard to the second embodiment, by Image 6 and Figure 7 for clarification.

[0104] The difference between the second embodiment and the first embodiment is that in the first embodiment, the flange is extruded on the plane part of each component part, while in the second embodiment, the molding process is carried out on the plane part of each component part. Therefore, since the components of the basic steel storage box for outdoor use and the manufacturing method thereof are merely extruded flanges replaced with press processing, description thereof will be omitted. The door 19 is an example in which the door of the outdoor steel storage box 1 is molded. Embossing is to press free-form shallow concave or convex parts on steel plates. The embossed part 71 of the door 19 has a convex shape with a height of about 5 mm formed on the inner side of the bent part from the door 19 up, down, left, and right by about 40 mm, and the rounded corners are approximately sq...

Embodiment 3

[0106] As for the third embodiment, by Figure 8 and Figure 9 for clarification.

[0107] The difference between the third embodiment and the first embodiment is that in the first embodiment, the flange is extruded on the plane part of each component, while in the third embodiment, the flange is extruded and molded on the plane part of each component. Therefore, since the components of the basic steel storage box for outdoor use and the manufacturing method thereof are only extruded flanges replaced with extruded flanges and molded, the description thereof will be omitted. The door 20 is an example in which the door of the steel storage box 1 for outdoor use is subjected to press molding. The embossed part 72 has a circular shape with a diameter of about 60 mm at the approximate center of the door 20 and a convex shape with a height of about 5 mm toward the outside of the outdoor steel storage box. Again, the shapes of the extruding flange portions 59, 60, 61, 62 are all t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com