Vibration-damping urethane resin composition, vibration-damping molded urethane resin object, and method for forming said molded object

A urethane and resin composition technology is applied in chemical instruments and methods, materials for heat exchange, non-rotational vibration suppression, etc. The effect of less deformation, high loss coefficient, and excellent resistance or impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

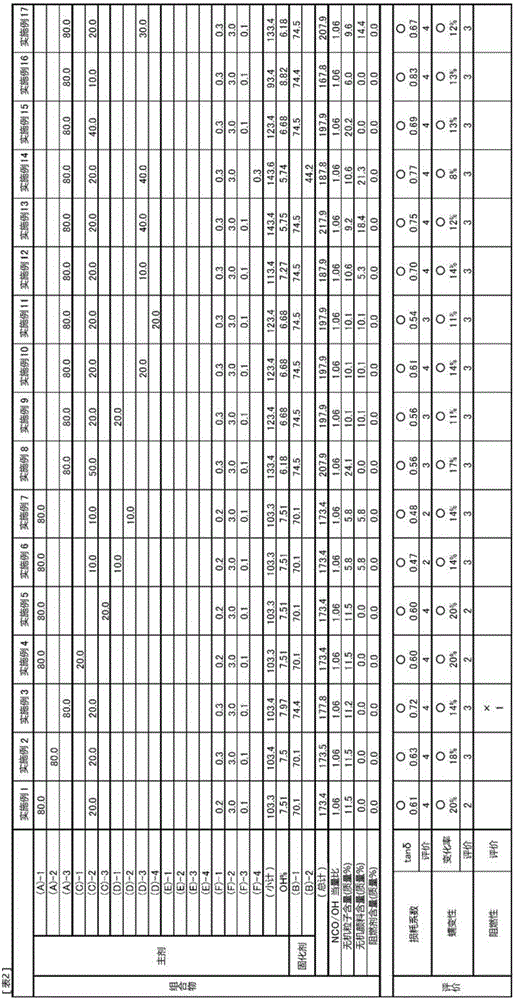

Embodiment 1

[0159] Put 80.0 parts of castor oil polyol URIC H-102 (manufactured by Ito Oil Co., Ltd.) and 20.0 parts of Riken resin LA-15-100 (manufactured by Miki Riken Industry Co., Ltd.) into the container so as not to damage the microcapsule shell. Method Use a high-speed disperser to disperse for 10 minutes at a speed of 500 rpm or less. Then, 0.2 parts of Toray Dow Corning SAG-47 (manufactured by Toray Dow Corning Co., Ltd.), 3.0 parts of molecular sieve 4A powder (manufactured by Union Showa Co., Ltd.), and 0.1 part of 10% GLECK TL (manufactured by DIC Corporation) were sequentially added Afterwards, stir and prepare the main agent. Next, 70.1 parts of MILLIONATE MTL (manufactured by Nippon Polyurethane Industry Co., Ltd.) was added as a curing agent under the condition of NCO / OH=1.06 with respect to the main ingredient, mixed and then defoamed to prepare a urethane resin composition.

[0160] The defoamed urethane resin composition was poured into a molding frame of 100×100×25 mm...

Embodiment 2~17、 comparative example 1~7

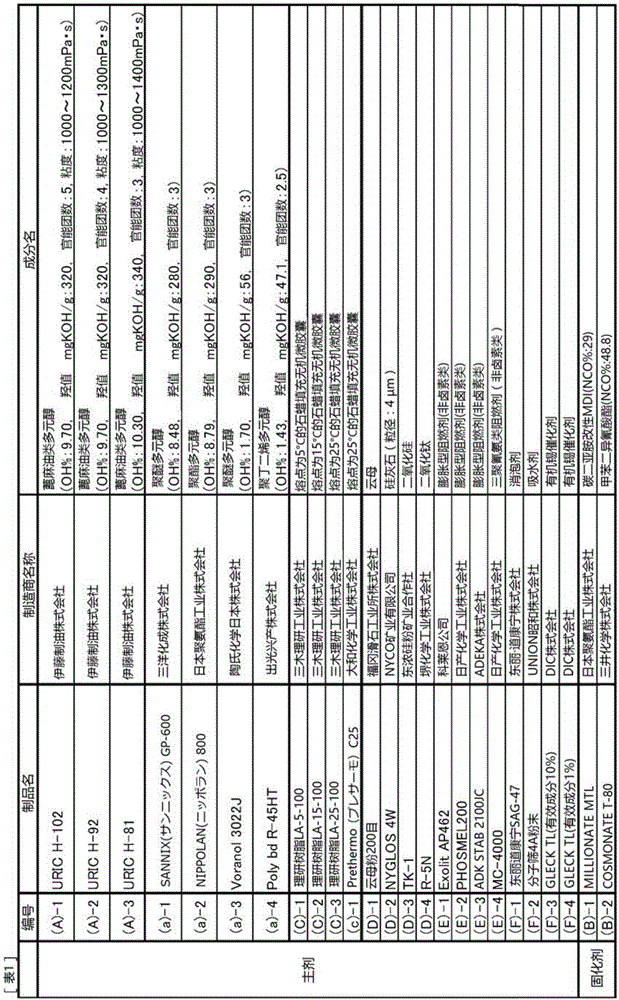

[0162] Except changing the kind and usage amount of raw materials as shown in Table 2 or Table 4, prepare the urethane resin composition in the same manner as in Example 1, except using the obtained composition, follow the same method as in Example 1 A urethane resin molded body was obtained in a manner. In addition, details of each material in Table 2 or Table 4 are shown in Table 1.

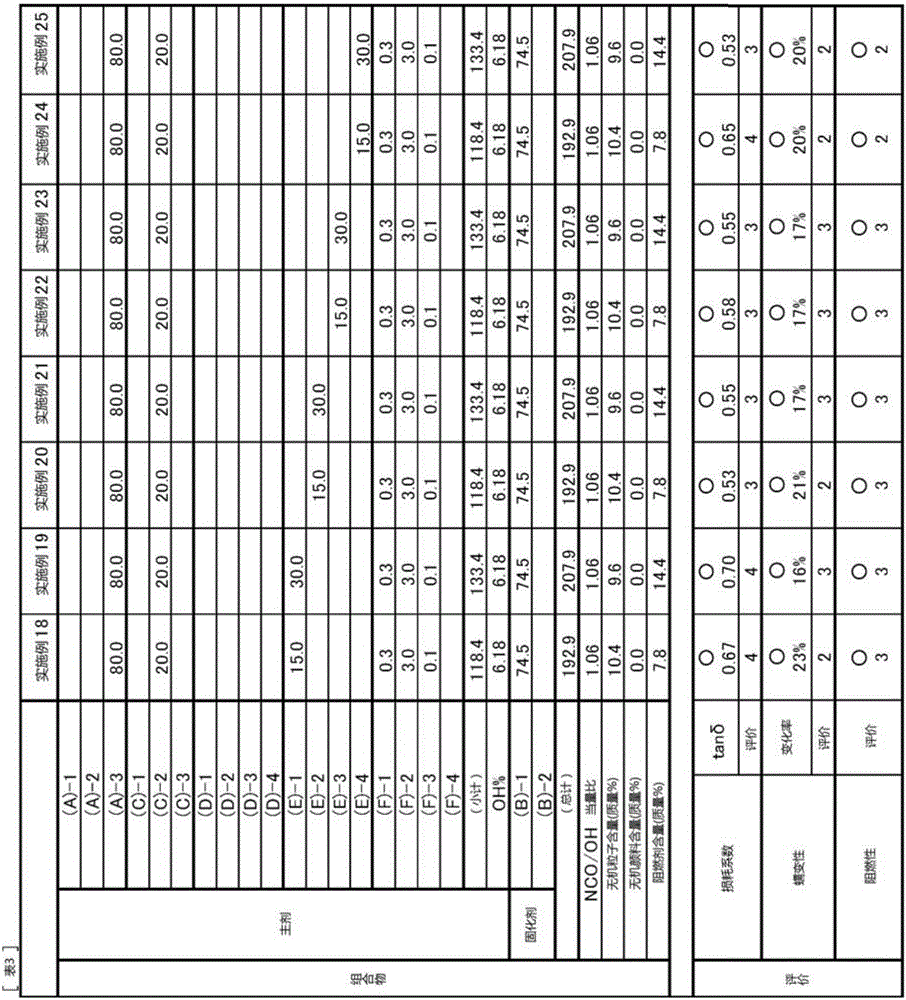

Embodiment 18

[0164] 80.0 parts of castor oil-based polyol URIC H-81 (Ito Oil Co., Ltd.) and 15.0 parts of Exolit AP462 (manufactured by Clariant) were put into a container, and dispersed at 1000 rpm for 15 minutes with a high-speed disperser. Then, 20.0 parts of Riken Resin LA-15-100 (manufactured by Miki Riken Industry Co., Ltd.) was blended, and the microcapsule shells were not damaged by dispersing with a high-speed disperser at a rotation speed of 500 rpm or less for 10 minutes. After the dispersion process, 0.3 parts of Toray Dow Corning SAG-47 (manufactured by Toray Dow Corning Co., Ltd.), 3.0 parts of molecular sieve 4A powder (manufactured by UNION Showa Co., Ltd.), and 0.1 part of 10% GLECK TL (manufactured by DIC Corporation) were added in sequence. manufactured by the company) and then stirred to prepare the main ingredient. Next, 74.5 parts of MILLIONATE MTL (manufactured by Nippon Polyurethane Industry Co., Ltd.) was added as a curing agent under the condition of NCO / OH=1.06 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com