High strength direct cooling type bush of sugar cane press

A direct-cooling, high-strength technology, applied to presses, extracting juice from sugarcane, manufacturing tools, etc., can solve the problems of increasing the production cost of sugar factories, increasing working hours and workload, and achieving increased rigidity and cooling speed The effect of speeding up and not easily deforming the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

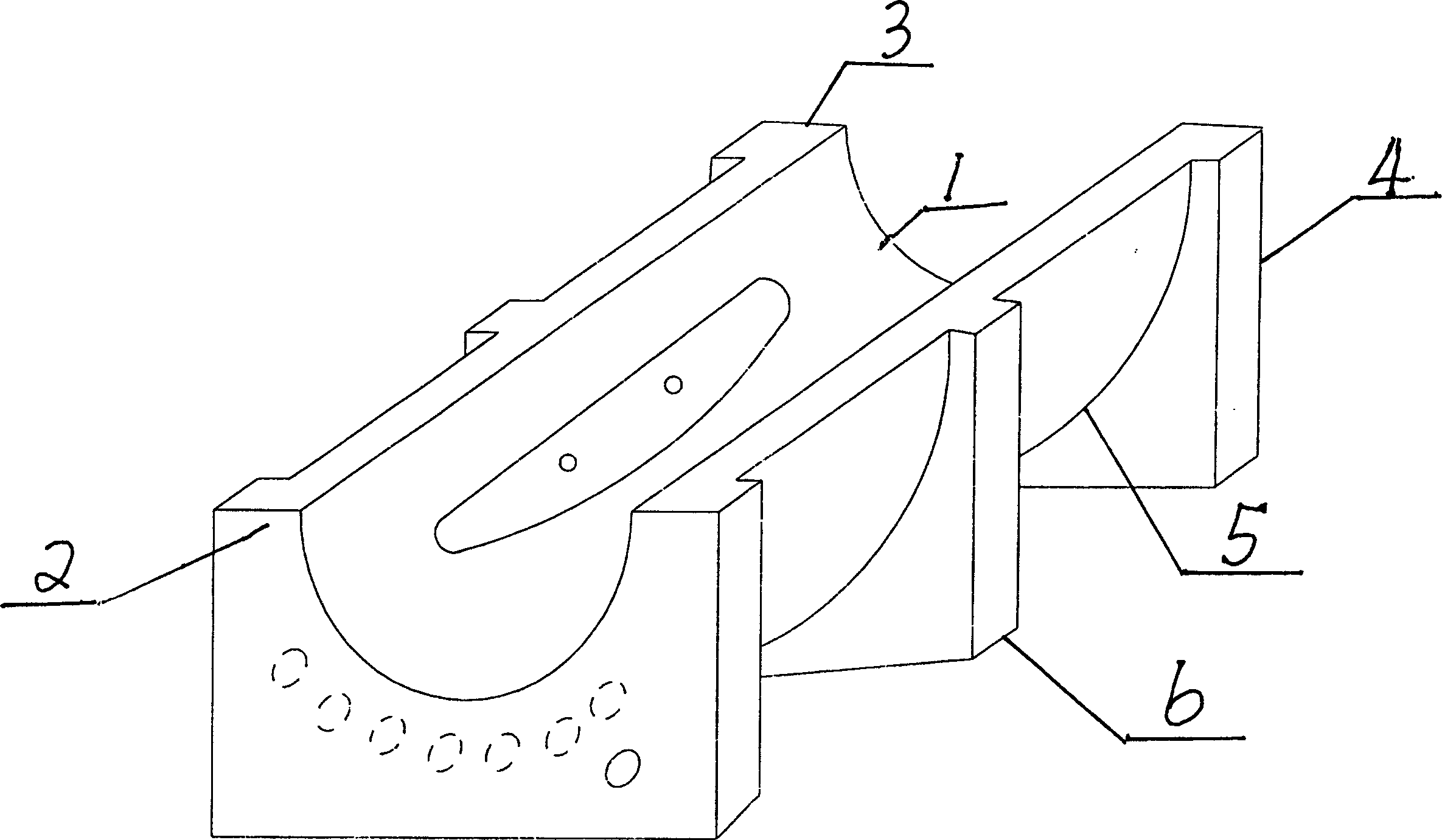

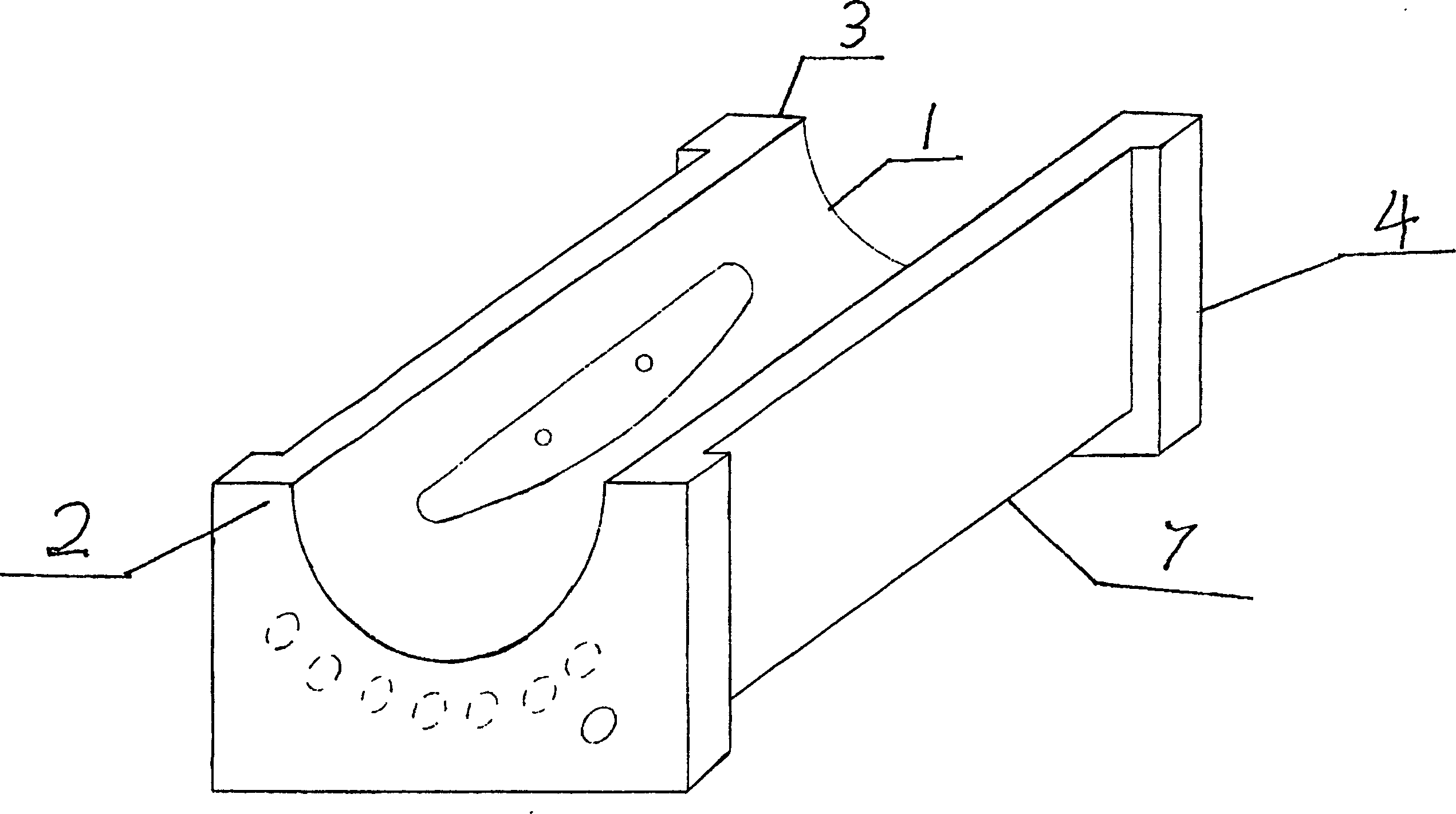

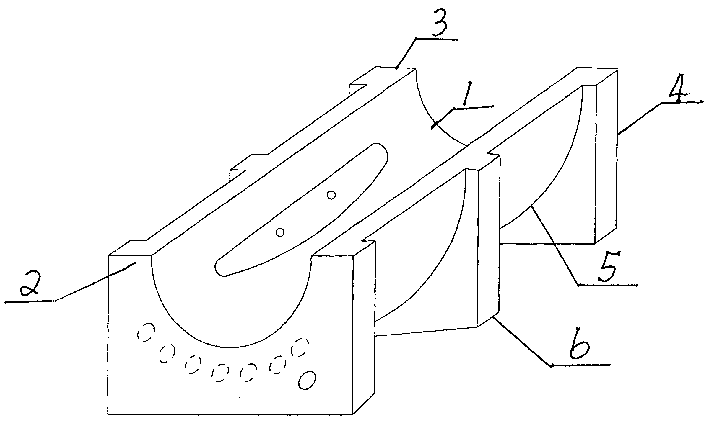

[0008] attached figure 1 , 2 As shown, the inner cylindrical surface 1 of the bearing bush; the two ends 2, 3 of the bearing bush; the flanges 4 at both ends; the semi-eccentric cylindrical outer surface 5 of the bearing bush; the flange 6 added to the weak part of the bearing bush; the rectangular outer surface 7 of the bearing bush .

[0009] On the outer surface 5 of the semi-eccentric cylinder of the bearing bush, 1 to 3 flanges 6 with a rectangular cross-sectional area are arranged, which are similar to the flanges 4 at both ends of the bearing bush. In the middle of the connecting line, or in the middle of the connecting line between two adjacent flanges, from one side of the bearing bush, along the radial direction of the bearing bush to the other side of the bearing bush, the cross section of the flange 6 can be rectangular, or semicircular, Trapezoid, triangle or any other geometric shape. The width of the flange 6 is 15mm-100mm, and the height of the flange 6 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com