Chip module with high radiating performance and its substrate

A high heat dissipation, chip module technology, used in electrical components, electrical solid devices, circuits, etc., can solve the problems of shortened component life, reduced component efficiency, poor thermal conductivity, etc., to achieve good heat dissipation properties and lighten the structure. The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

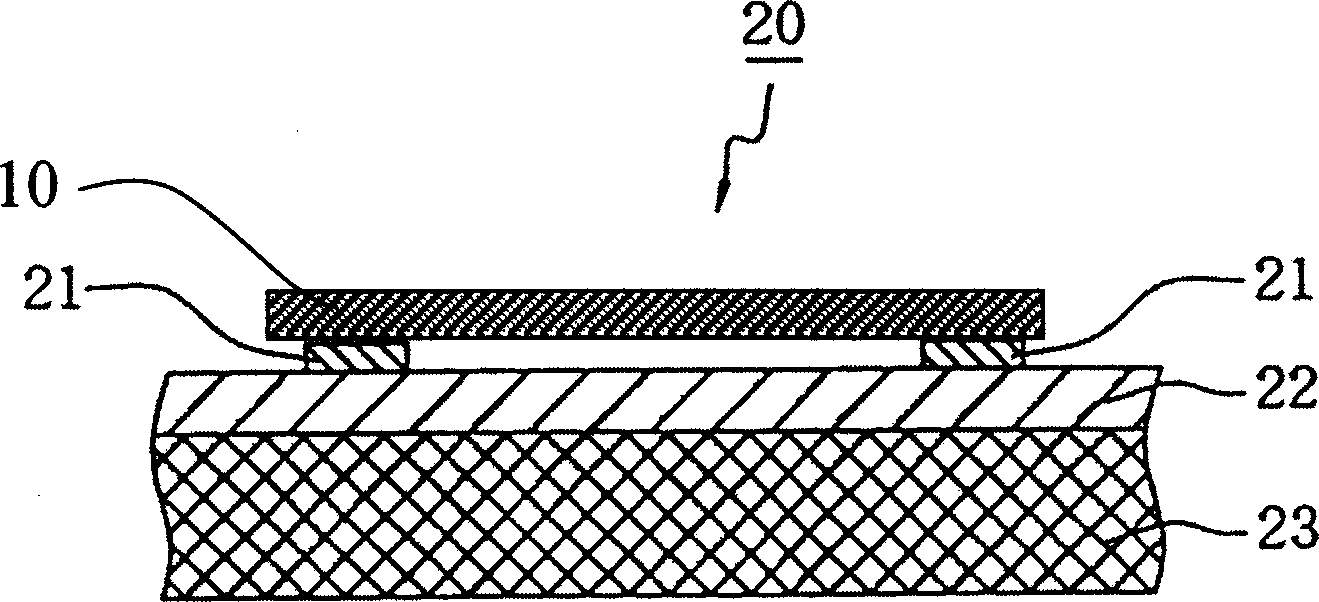

[0043] figure 1 It is a structural schematic diagram of a single-layer substrate of the chip module of the present invention. A layer of insulating layer 22 is covered on the top of a metal composite plate 23. The insulating layer is a metal compound of the metal composite plate, that is, an oxide film layer or a nitride film layer, or an insulating ceramic material or polymer material deposited on the metal composite plate. The surface of the sheet 23. The known composite substrate can be replaced by the insulating film 22 , that is, as an electrical insulator between the circuit layer 21 and the metal composite plate 23 . For example, an aluminum-based composite material is used as the material of the metal composite plate 23, and an insulating film layer of aluminum oxide or aluminum nitride is formed on the surface of the aluminum-based composite material. It can be seen from Table 1 that the thermal conductivity of aluminum is 237W / M.K, that of aluminum oxide is 46W / M.K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com