Housing for the drive of an electrical device, particularly a household appliance

A technology for household appliances and driving devices, applied in electromechanical devices, cleaning equipment, electric components, etc., can solve the problems of reduced strength, deterioration of cooling of electric driving devices, poor thermal conductivity of plastics, etc. The effect of shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

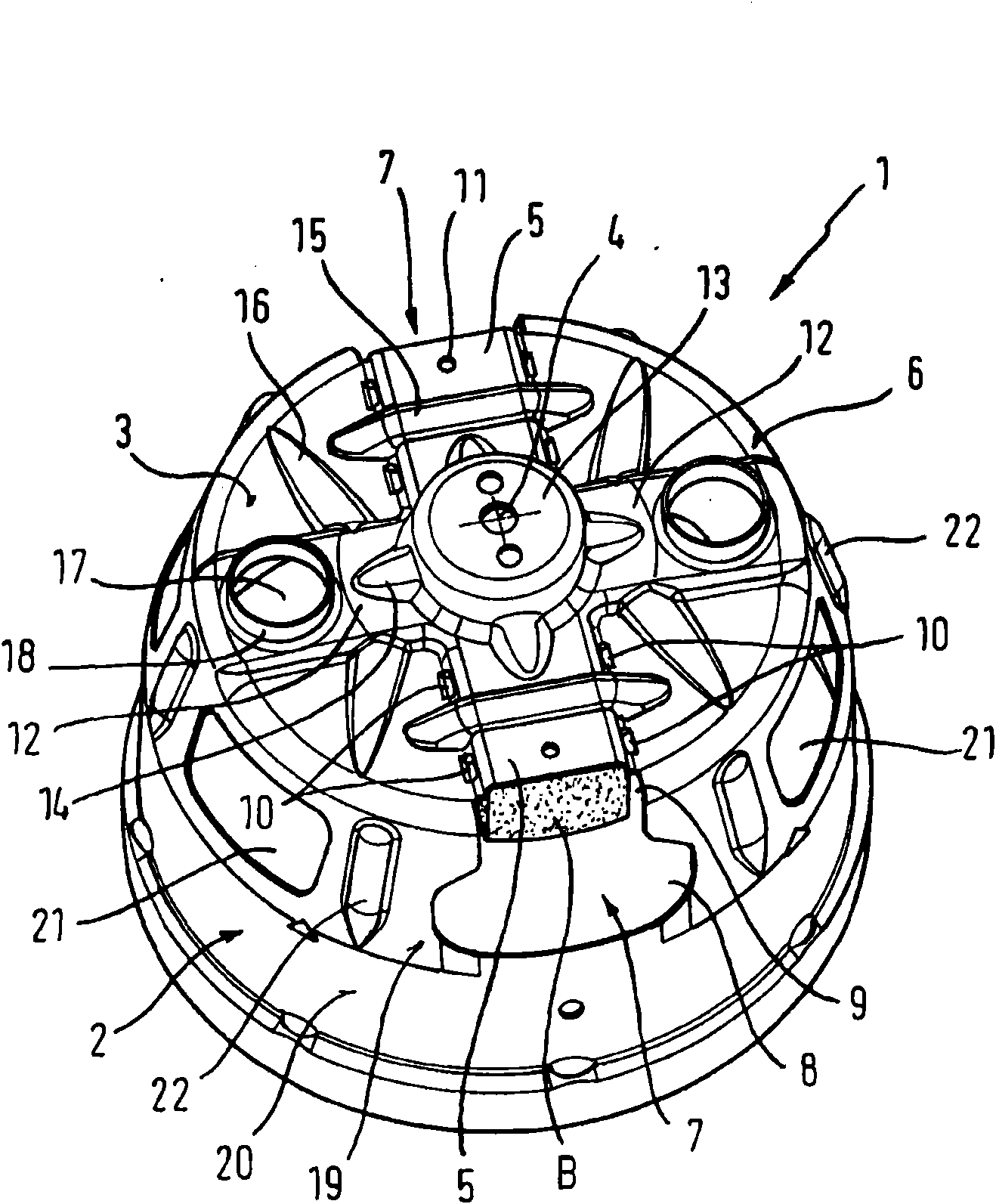

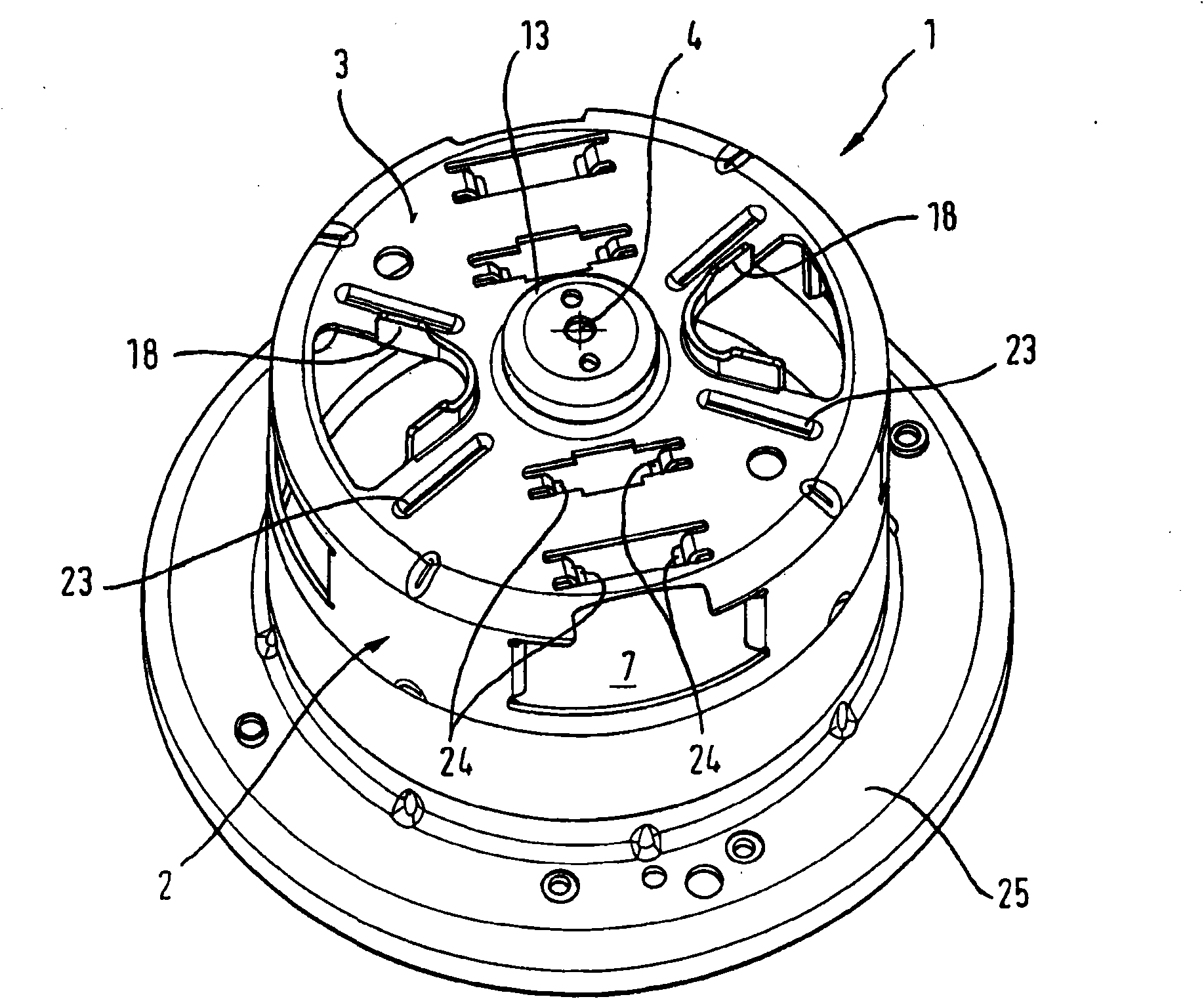

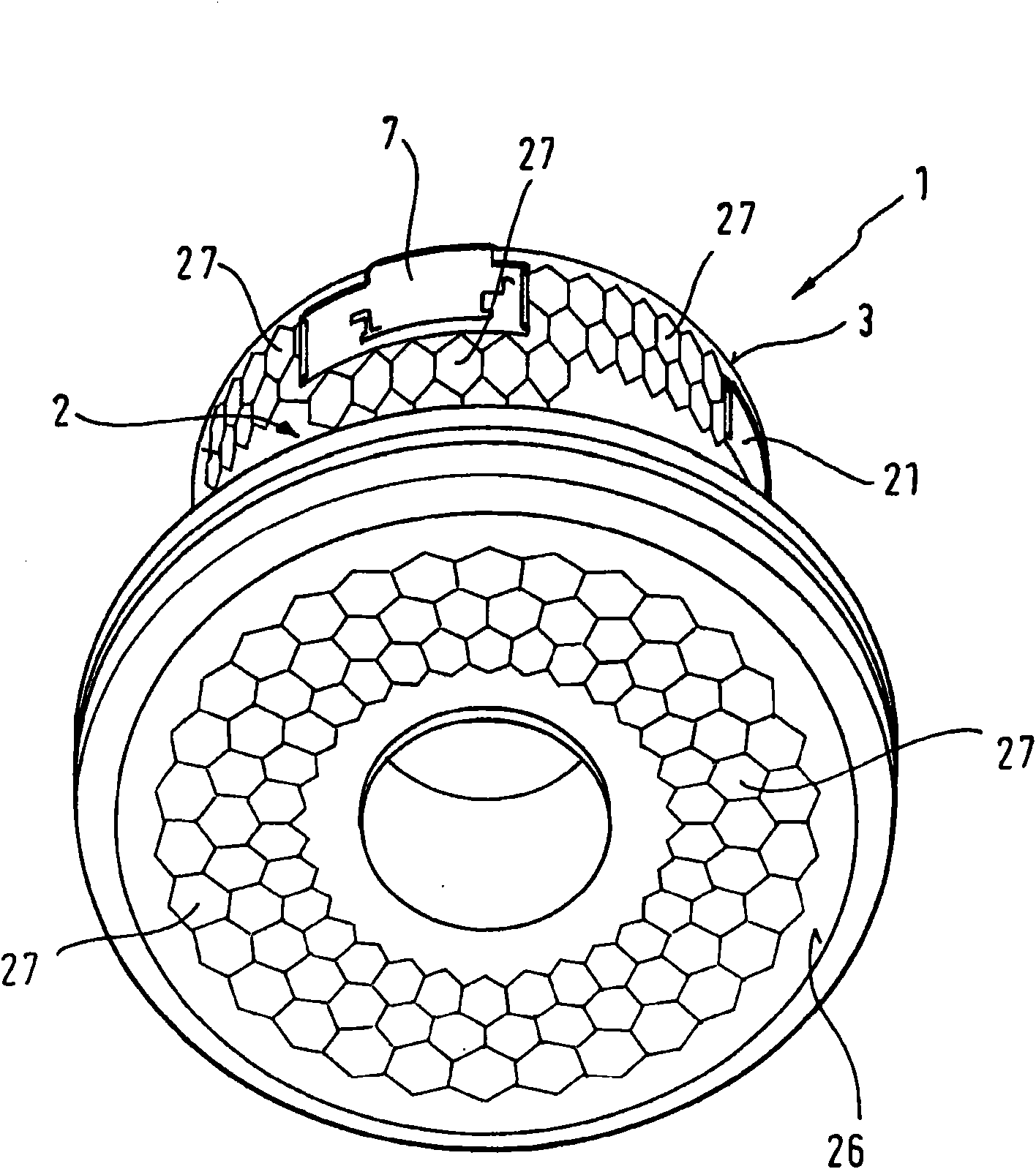

[0035] exist figure 1 The housing 1 shown in is used to accommodate and position an electric drive, in this embodiment for an electric household appliance. The housing 1 is formed by stamping from a relatively thin metal plate, especially a steel plate with a thickness of less than 1.0 mm. In this embodiment, the plate thickness of 0.8 mm is sufficient to withstand the static and dynamic loads generated when the household appliance is in operation.

[0036] The bowl-shaped housing 1 is composed of a radial wall 2 and an upper end wall 3 and is designed to be open at the bottom. The positional descriptions here relate to customary, but not mandatory, installation positions of the housing 1 .

[0037] Transversely across the front wall 3 and through its center 4 , first channel-shaped embossments 5 extend through their mutually opposite end regions as far as the circumference 6 of the front wall. The rectilinear punching marks 5 have a U-shaped cross section and are curved ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com