Thermal fatigue testing machine

A thermal fatigue and testing machine technology, which is applied in thermal analysis of materials, measuring devices, instruments, etc., can solve problems such as unsatisfactory thermal fatigue test results, and achieve good cooling effect, less thermal deformation, and small temperature difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

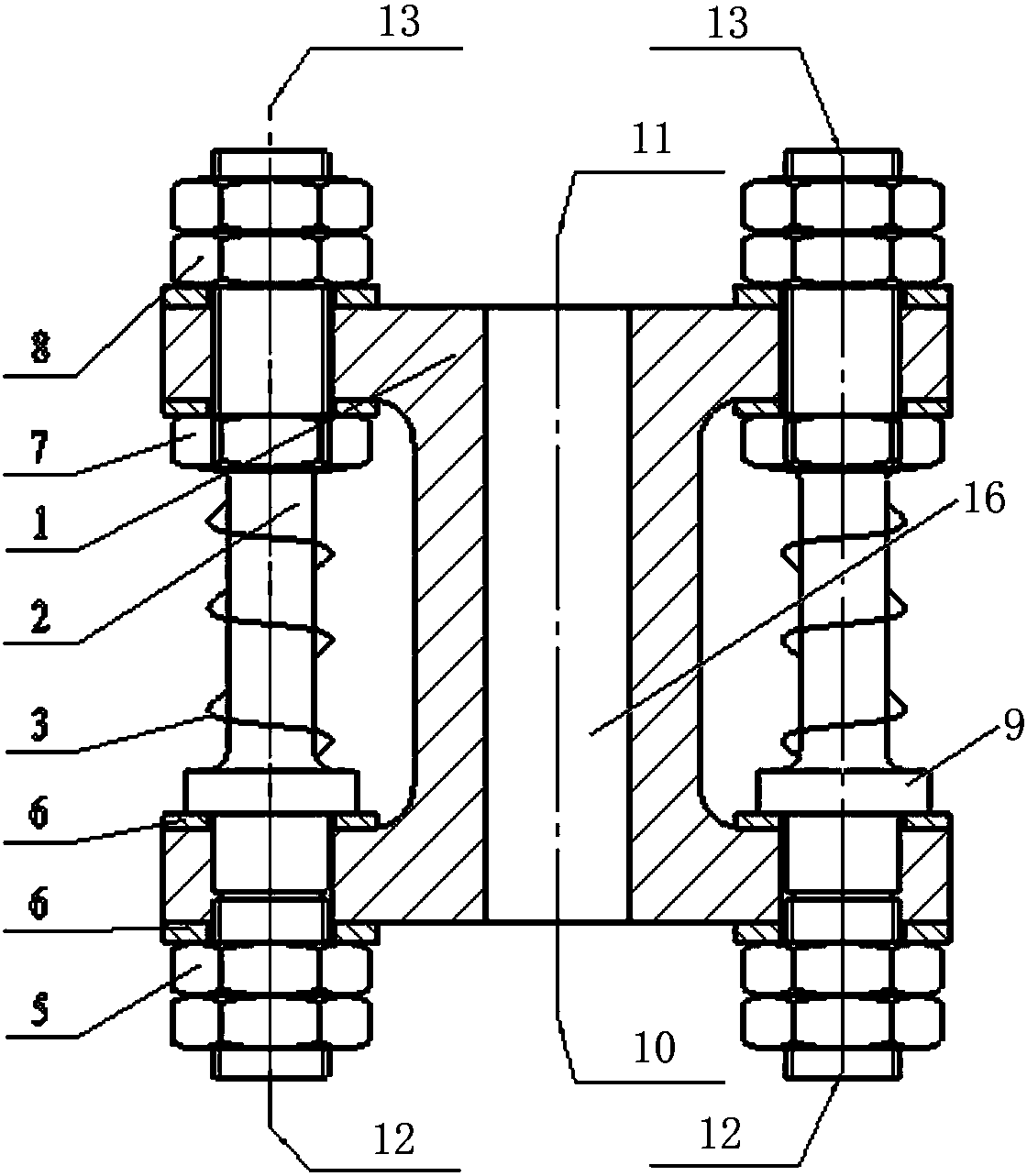

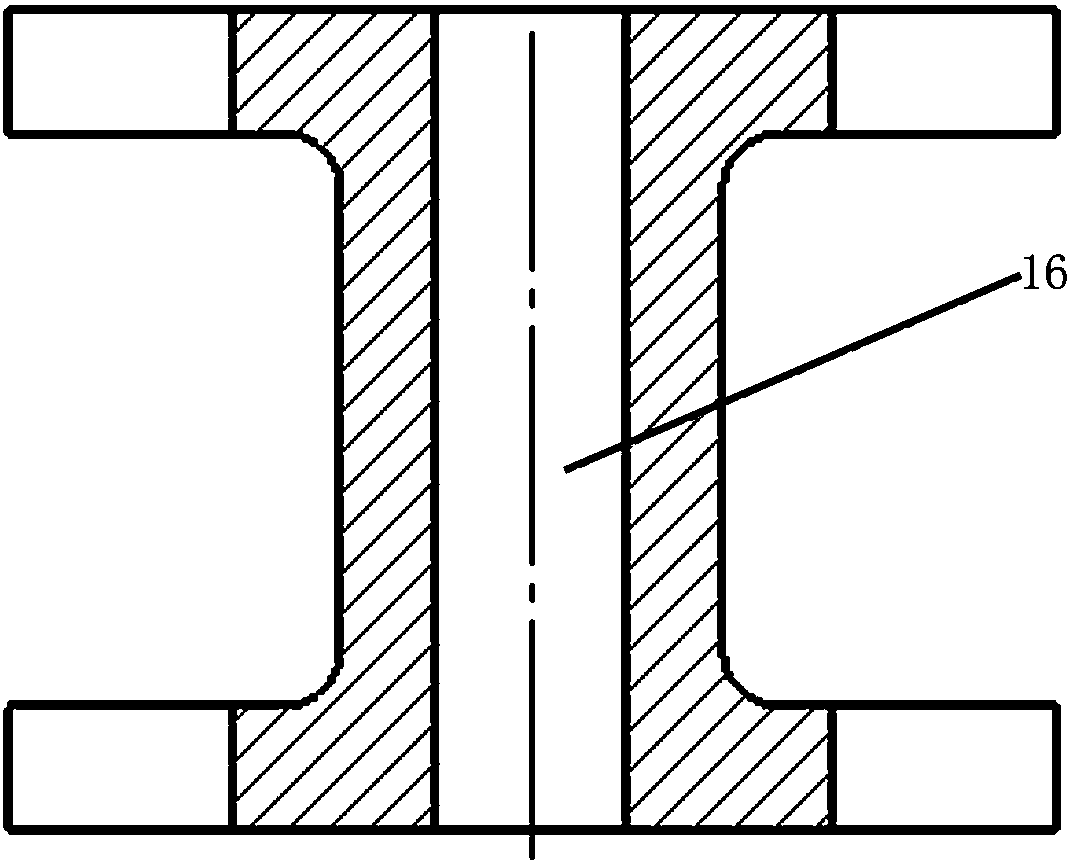

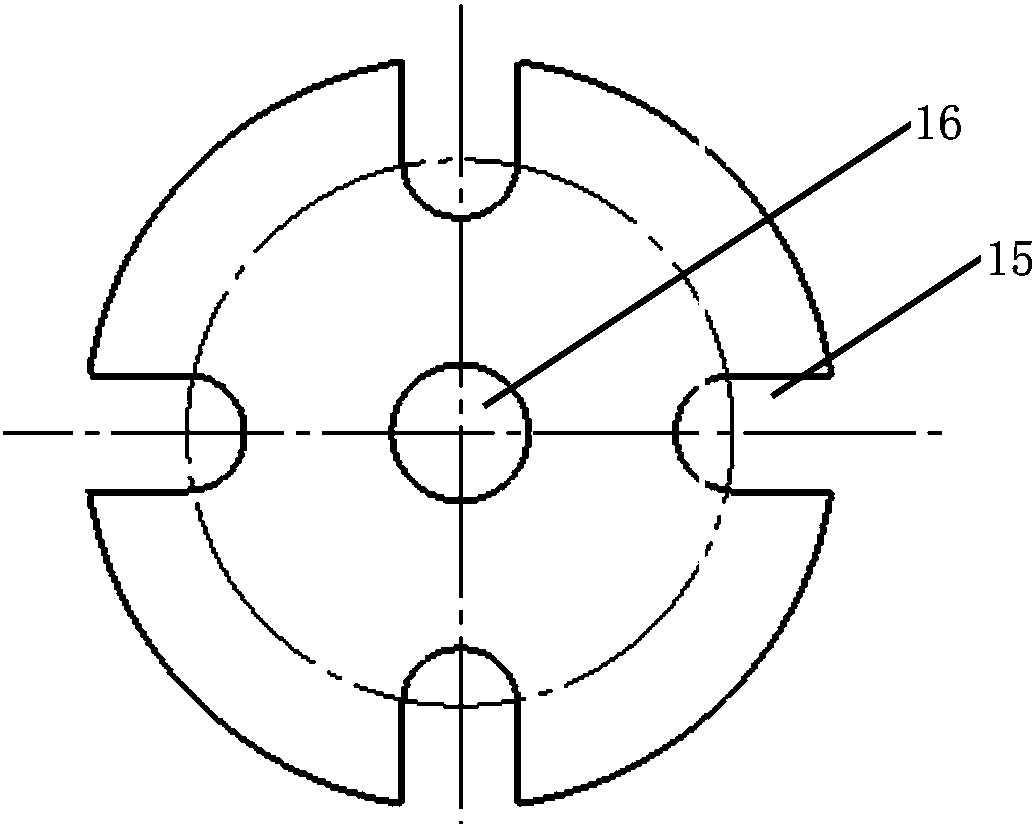

[0030] Such as figure 1 As shown, the present invention provides a thermal fatigue testing machine, which includes a support 1 and a thermal fatigue sample 2; the support 1 is a pillar structure with flanges up and down, and the main body of the support 1 is cylindrical. The center of the support 1 is provided with a support cooling channel 16, the upper part of the thermal fatigue sample 2 is stuck at the upper flange of the support 1 and the lower part is stuck at the lower flange of the support 1, and the outer wall of the thermal fatigue sample 2 is wound with an induction Heating coil 3.

[0031] Such as Figure 4 As shown, the thermal fatigue sample 2 is a thin-walled cylindrical structure with a central hole, and the central hole is the sample cooling channel 14 .

[0032] The thermal fatigue sample 2 has a structure with external threads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com