engine timing cover

A timing cover and engine technology, which is applied to engine components, machines/engines, casings, etc., can solve the problems of heavy workload, high maintenance cost, long time consumption, etc., to reduce maintenance workload and facilitate accurate control. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail in conjunction with accompanying drawing now.

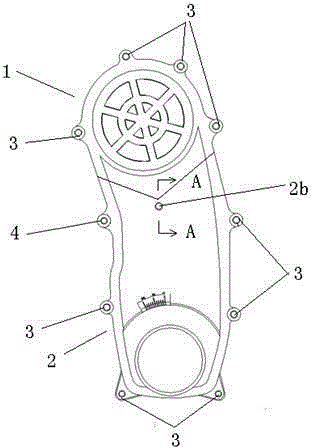

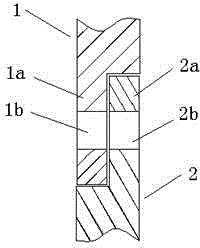

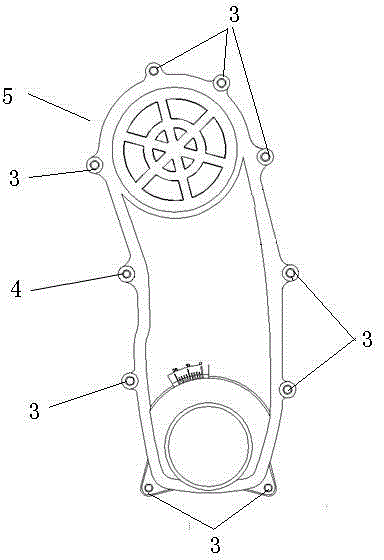

[0013] Such as figure 1 and figure 2 The engine timing case shown has mounting lugs 3 and water pump mounting lugs 4 on its edge, which are formed by overlapping the upper timing case 1 and the lower timing case 2, and the upper timing case 1 is provided with a first lapped step 1a, and the lapped side of the lower timing cover 2 is provided with a second lapped step 2a, and the upper and lower timing covers 1 and 2 pass through the first and second laps. The connecting steps 1a and 1b are overlapped with each other, the first overlapping step 1a is provided with a first water pump installation hole 1b, and the second overlapping step 1b is provided with a second water pump installation hole 2b, between the upper timing cover 1 and the lower After the timing cover 2 is overlapped, the first and second water pump installation holes 1b and 2b coincide; the water pump i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com