Headlight for vehicle

A technology for headlights and vehicles, which is applied in the direction of headlights, vehicle parts, lighting devices, etc., and can solve the problems of thermal deformation of the reflector 4 and thermal deformation of the O-ring 8, and achieve the effect of not being easily thermally deformed and preventing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described below with reference to the drawings.

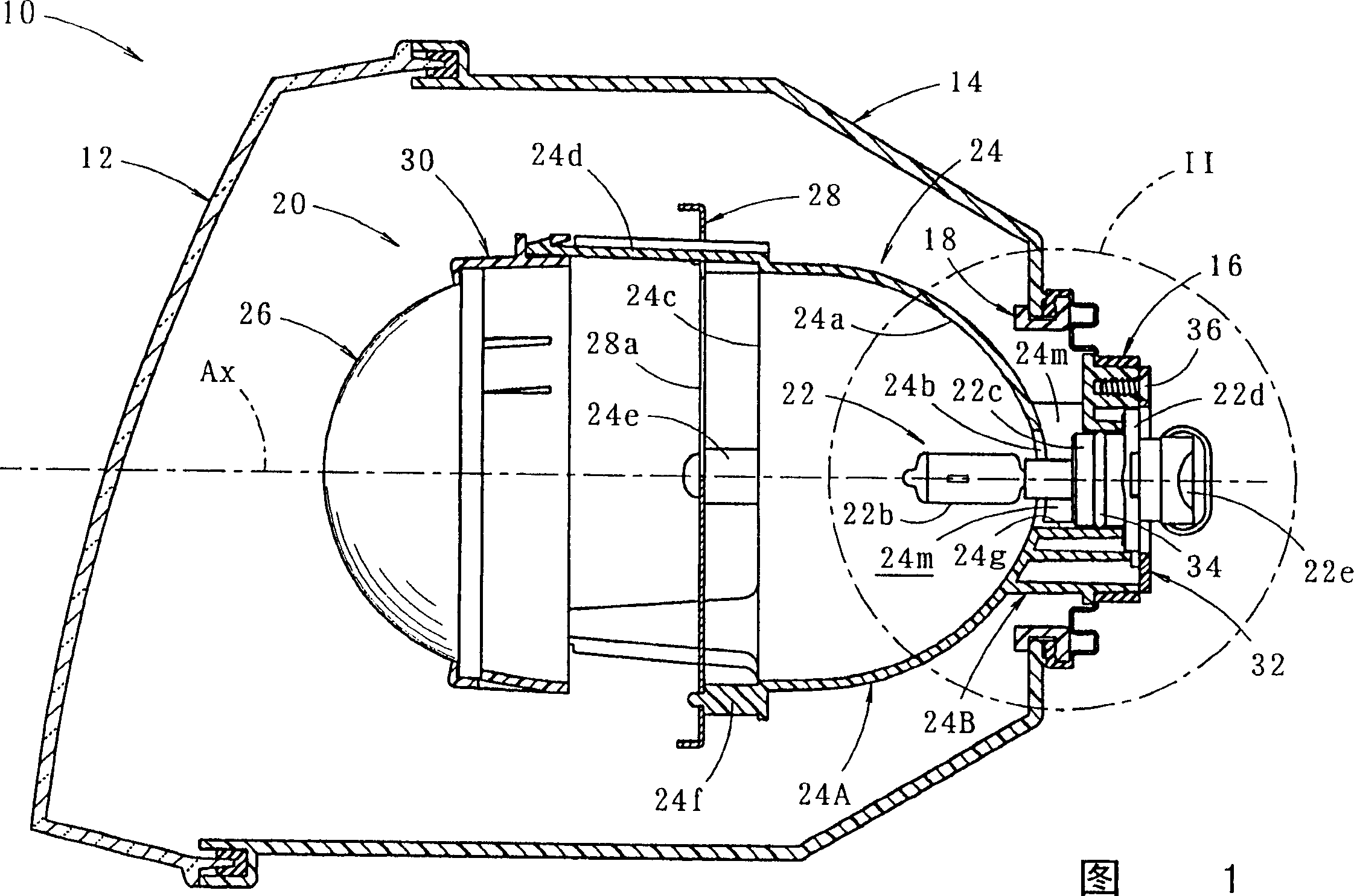

[0034] Fig. 1 is a side sectional view showing a vehicle headlamp according to an embodiment of the present invention.

[0035] As shown in the figure, the vehicle headlamp 10 of this embodiment is housed in a lamp chamber formed by a colorless and transparent cover body 12 and a lamp body 14, and can be tilted vertically and horizontally by an unillustrated aiming mechanism. The lamp assembly 20 in action.

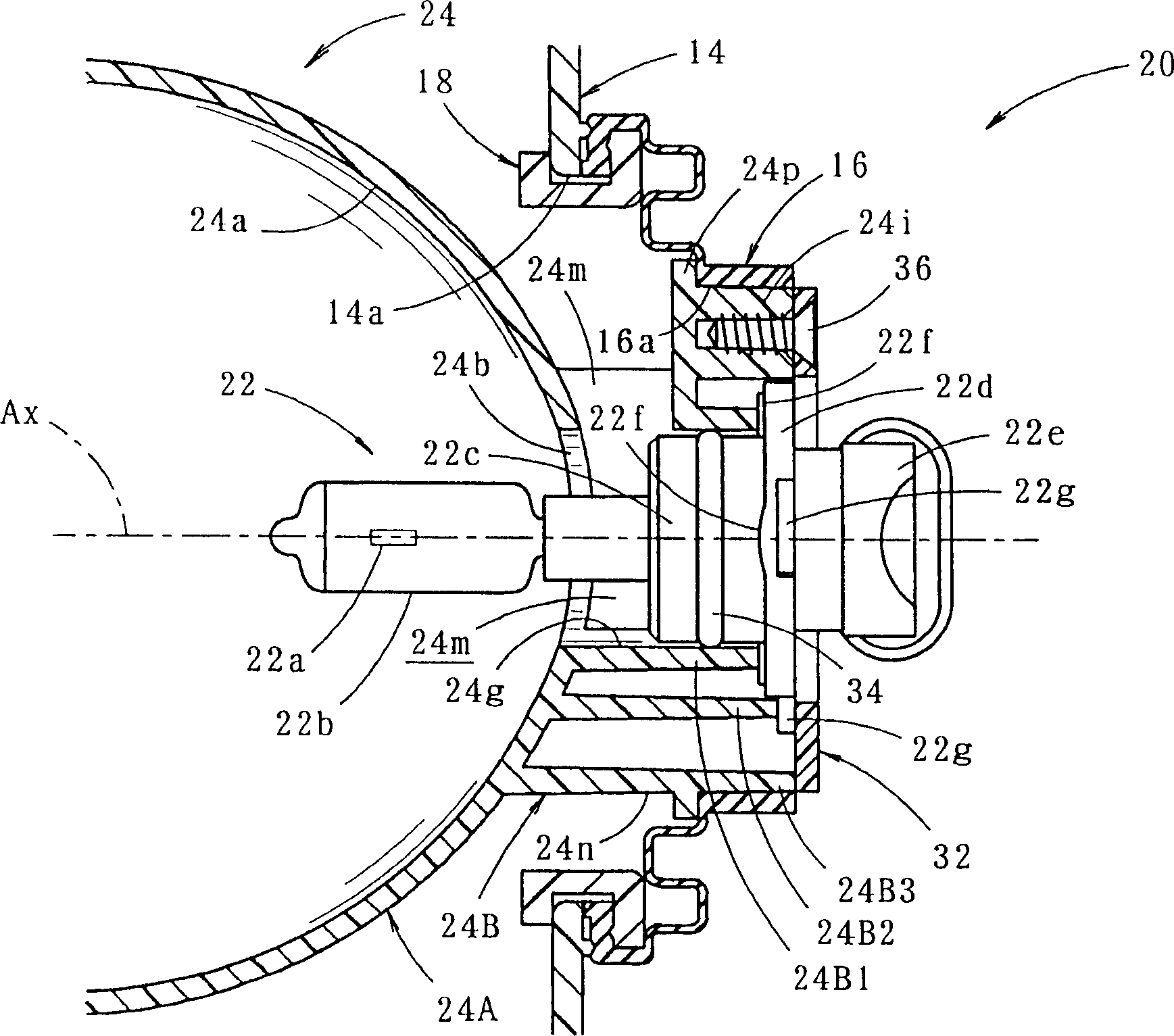

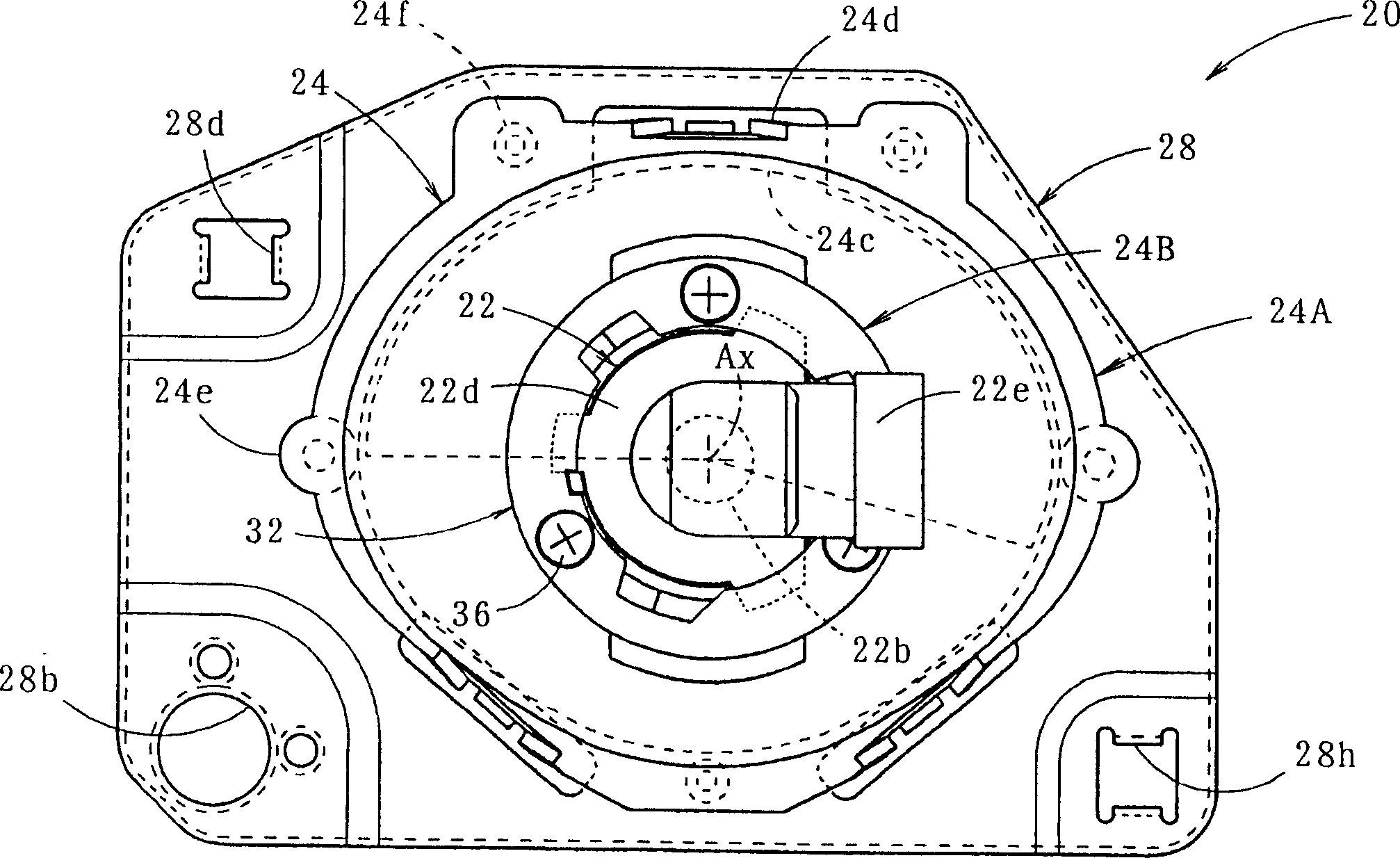

[0036] figure 2 It is a detailed diagram of Part II of Fig. 1, image 3 It is a rear view showing the lamp assembly 20 in a single form.

[0037] As shown in these figures, the lamp unit 20 is a so-called concentrating lamp unit, and includes a light source bulb 22 , a reflector 24 , a projection lens 26 , a shutter 28 , a lens holder 30 , and a bulb holder 32 .

[0038] The light source bulb 22 is a so-called HB4 type tungsten iodine lamp. That is, the light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com