Grinding roller of high-dispersion three-roller machine for conductive slurry production

A technology of conductive paste and grinding roller, which is applied in the direction of grain processing, etc., can solve the problems that affect the dispersion and grinding effect and efficiency, the three-roll machine cannot work for a long time, and affect the dispersion and grinding effect, so as to prolong the continuous working time and improve the grinding Dispersion efficiency, the effect of improving the grinding and dispersing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

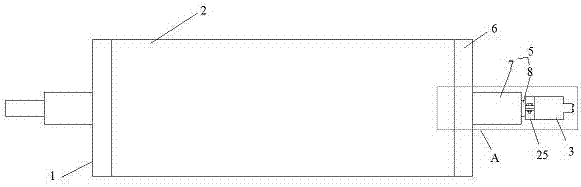

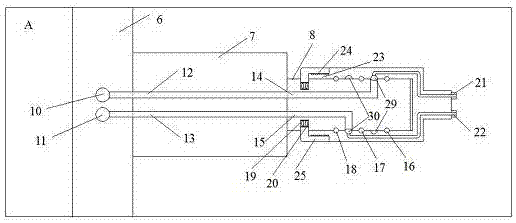

[0021] As shown in the figure, a grinding roller for a high-dispersion three-roll machine for the production of conductive paste includes a grinding roller 1, which is characterized in that the grinding roller 1 is arranged horizontally, including a roller main body 2, a liquid inlet and outlet sleeve The tube 3 and the rotating end 5 and the connecting plate 6 on one side of the roller body 2, the roller body 2 is a hollow cylinder, and the rotating end 5 includes a rotating shaft 7 and a liquid inlet and outlet shaft 8;

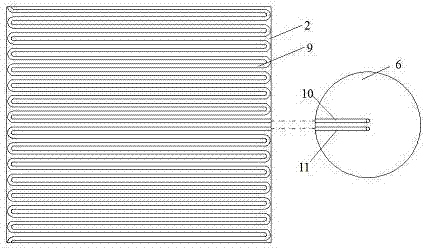

[0022] The roller main body 2 is provided with a cooling liquid channel 9, the cooling liquid channel 9 is coiled in an S shape, the connecting plate 6 is circular, and a first liquid inlet channel 10 and a first liquid outlet channel are arranged in it 11. The first liquid inlet channel 10 and the first liquid outlet channel 11 communicate with the two ends of the cooling liquid channel 9 respectively, and the rotating shaft 7 is a cylinder, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com