Apparatus for grinding and dispersing organic dyestuff

A technology for grinding and dispersing organic pigments is applied in the field of producing organic pigment grinding and dispersing devices for light resistance modulation of color filter pigments of liquid crystal displays, which can solve the problems of large energy consumption, long production cycle and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

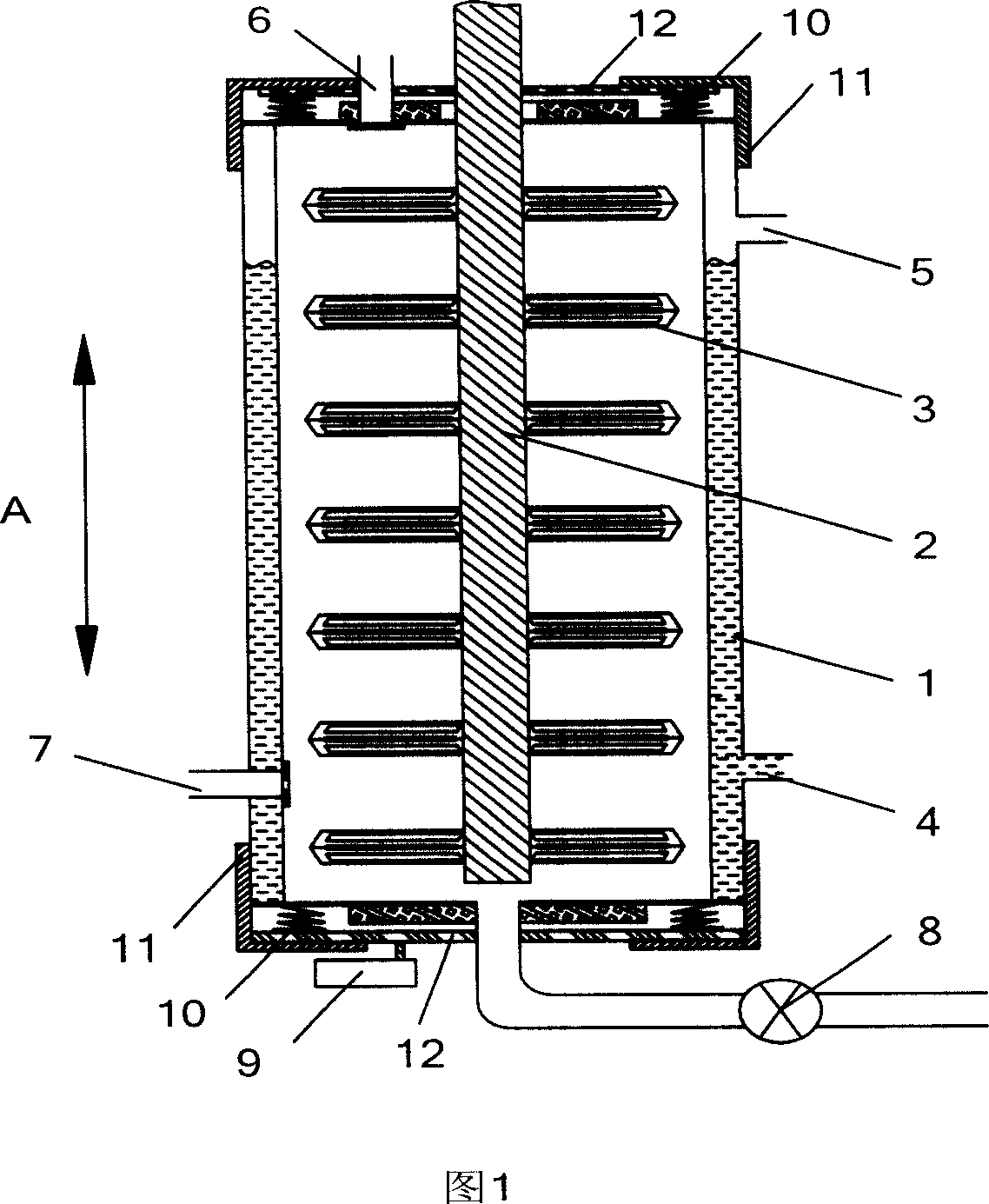

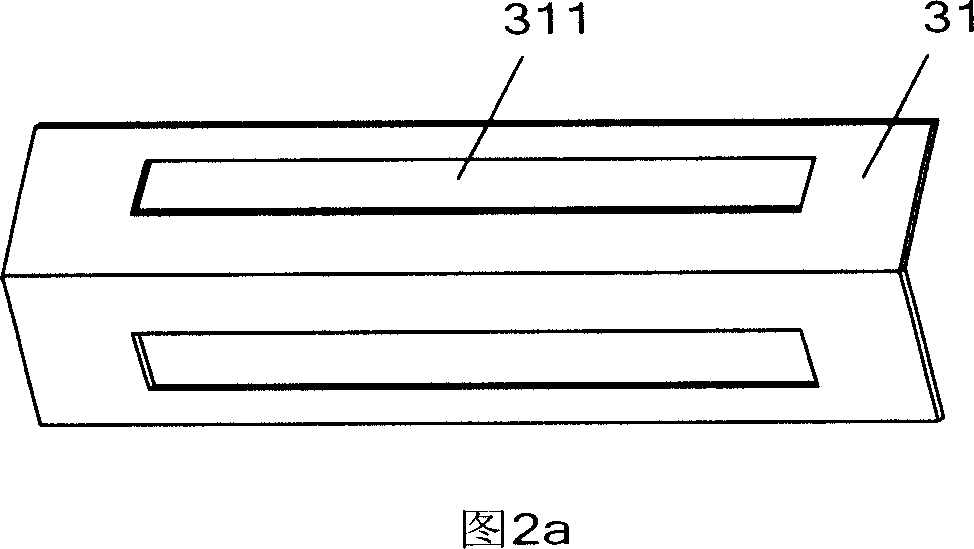

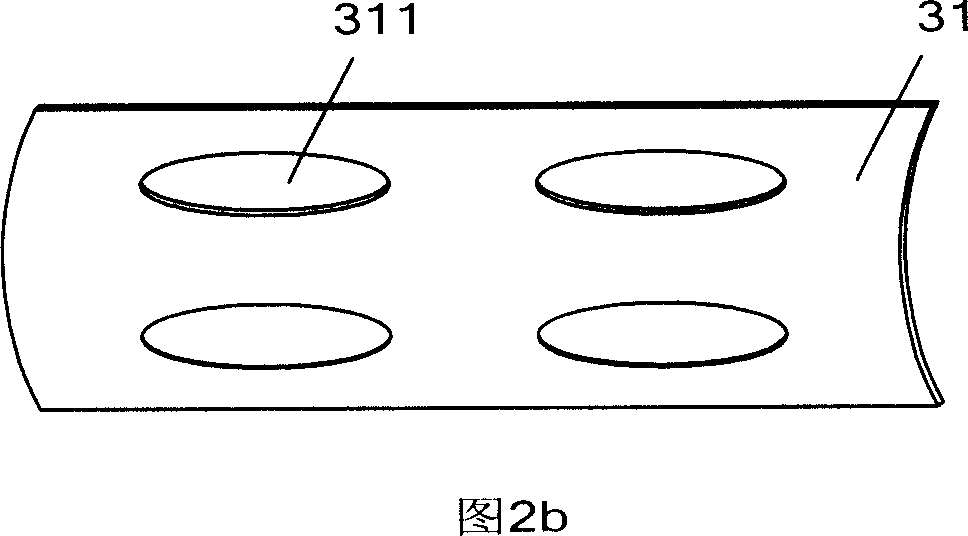

[0032] Fig. 1 is a schematic structural view of the organic pigment grinding and dispersing device of the present invention, the main structure includes a grinding cylinder 1, a rotating shaft 2 and a blade group 3, and the grinding cylinder 1 is provided with a cooling structure to maintain a certain temperature in the inner cavity and make it high along the axial direction One end of the rotating shaft 2 is inserted into the inner cavity of the grinding cylinder 1, and a plurality of blade groups 3 are fixed in sequence. Each blade set 3 has a plurality of grinding blades 31 uniformly distributed along the circumference of the rotating shaft 2 , and a through hole 311 is disposed on the surface of each grinding blade 31 . In the above structure, the distance between blade groups 3 can be the same or different, and the number of grinding blades 31 in each blade group 3 is determined according to the material properties, and can be 6-24.

[0033] The present invention adopts c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com