Positioning jig for numerical control machining thin-wall product side holes

A technology for positioning fixtures and products, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as heat deformation of processed parts, and achieve the effect of not being easily deformed by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

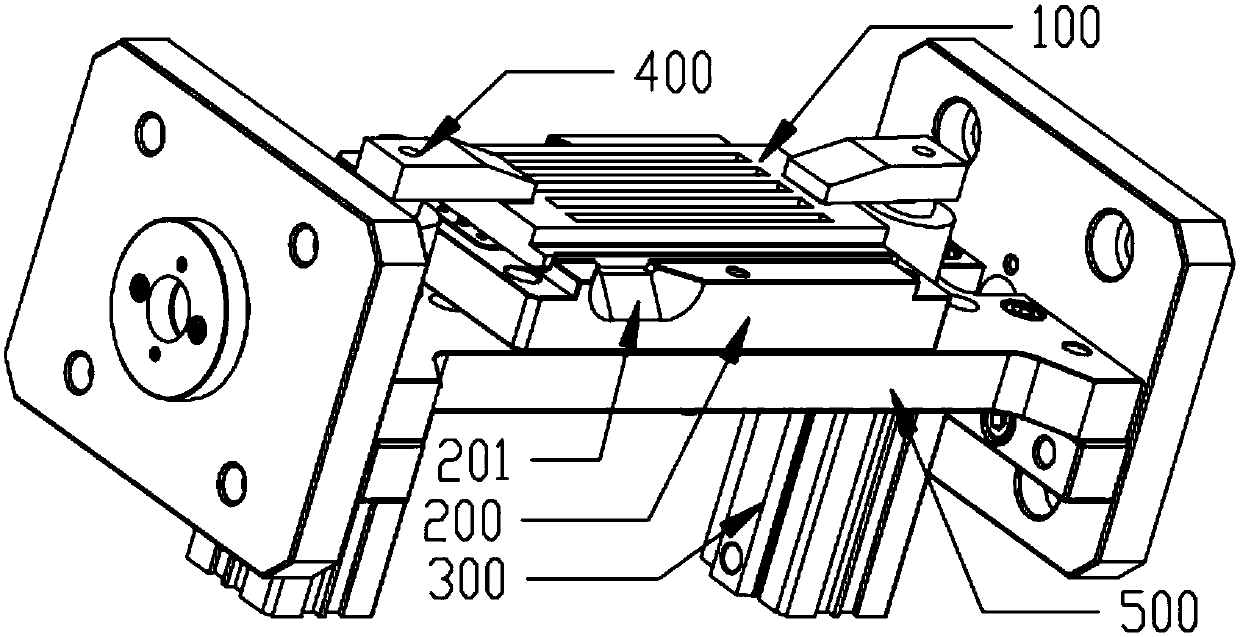

[0023] The present invention will be described in further detail below with reference to the pictures in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

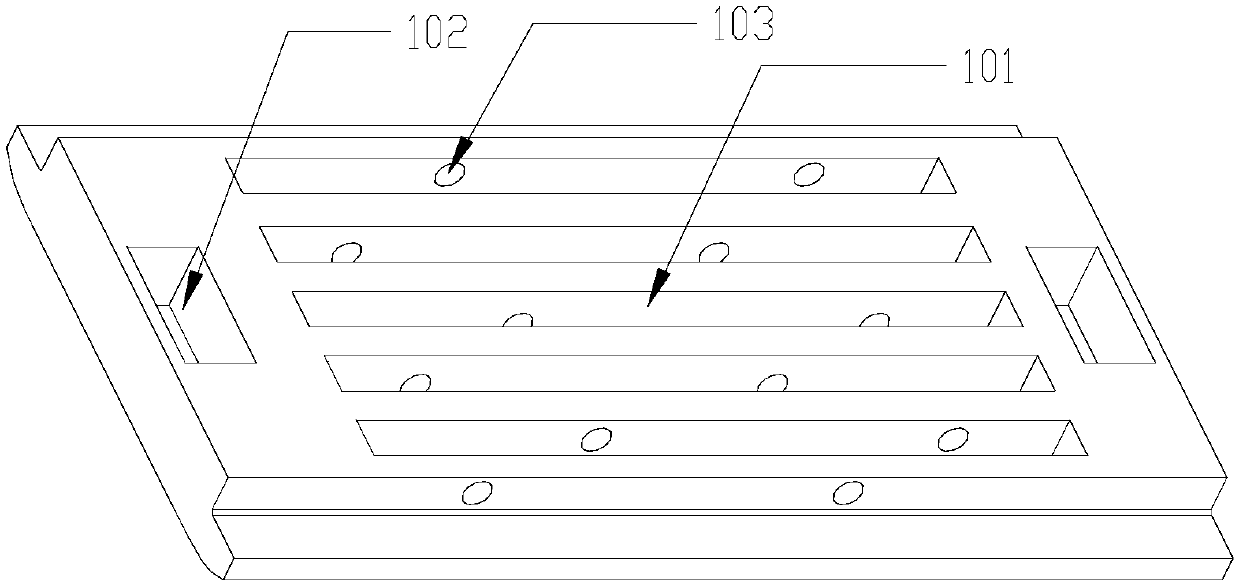

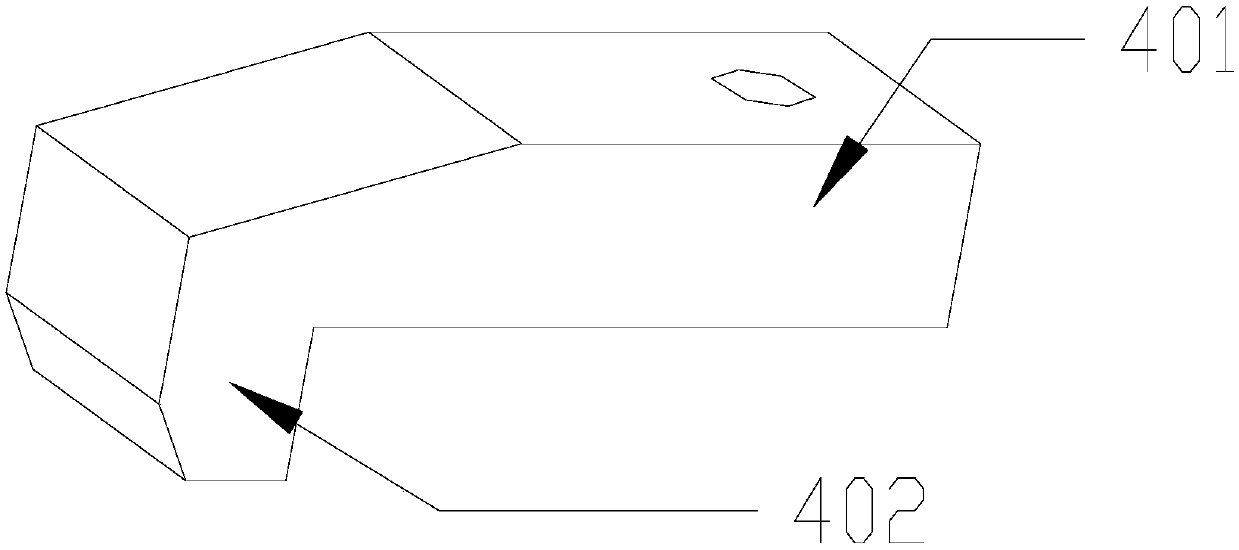

[0024] Such as figure 1 with figure 2 As shown, this case lists a positioning fixture for CNC machining of thin-walled products, which as a whole includes: base, positioning block, rigid guard plate, pneumatic device and cooling device.

[0025] The base 500 is installed on the CNC machine tool.

[0026] The positioning block 200 is laterally fixed on the base, and the workpiece is clamped on the positioning block 200 . A positioning column is respectively arranged on the longitudinal sides of the upper end surface of the positioning block 200, and a positioning hole is provided on the workpiece, and the workpiece is fixed at a specific position of the positioning block 200 through the hole column. The air outlet is connected to the air suction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com