Cooling type glass gathering iron

A cooling type and rod technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of bulky production cost, increase, and easy deformation of the pick rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

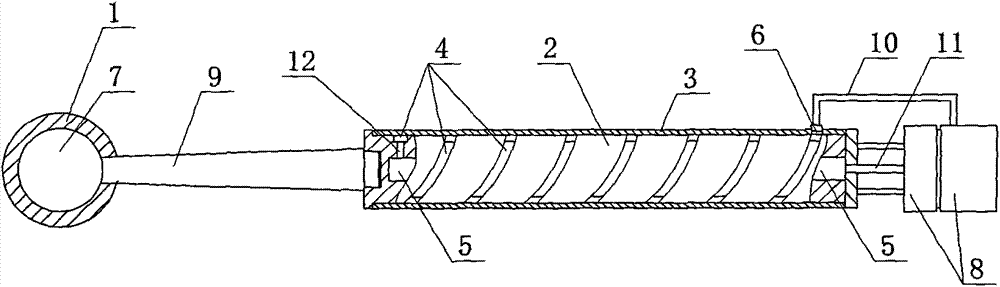

[0010] Such as figure 1 As shown, the cooled glass pick rod includes a water-cooled glass pick rod and includes a pick rod body and a pick ball 1 for being connected with a glass pick machine. For the convenience of description, the position of the pick ball is defined as Anterior, the opposite direction is defined as posterior. The body of the picking rod is composed of a tapered rod section 9 and a straight rod section that are screwed together. The picking ball 1 is screwed to the front end of the tapered rod section. The tapered rod section is made of a material with high thermal strength, such as molybdenum steel . In order to effectively reduce the weight of the pick ball, the pick ball 1 is a hollow structure with a cavity 7 inside. The straight rod section includes a mandrel 2, and a water inlet spiral groove is provided on the outer surface of the mandrel 2, and the outer surface of the mandrel 2 is tightly sleeved with a casing 3 that forms a sealing relationship w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com