Noise eliminating method and noise eliminating circuit

A technology of noise cancellation, power stage circuit, applied in the field of electronics, can solve problems such as increased circuit loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

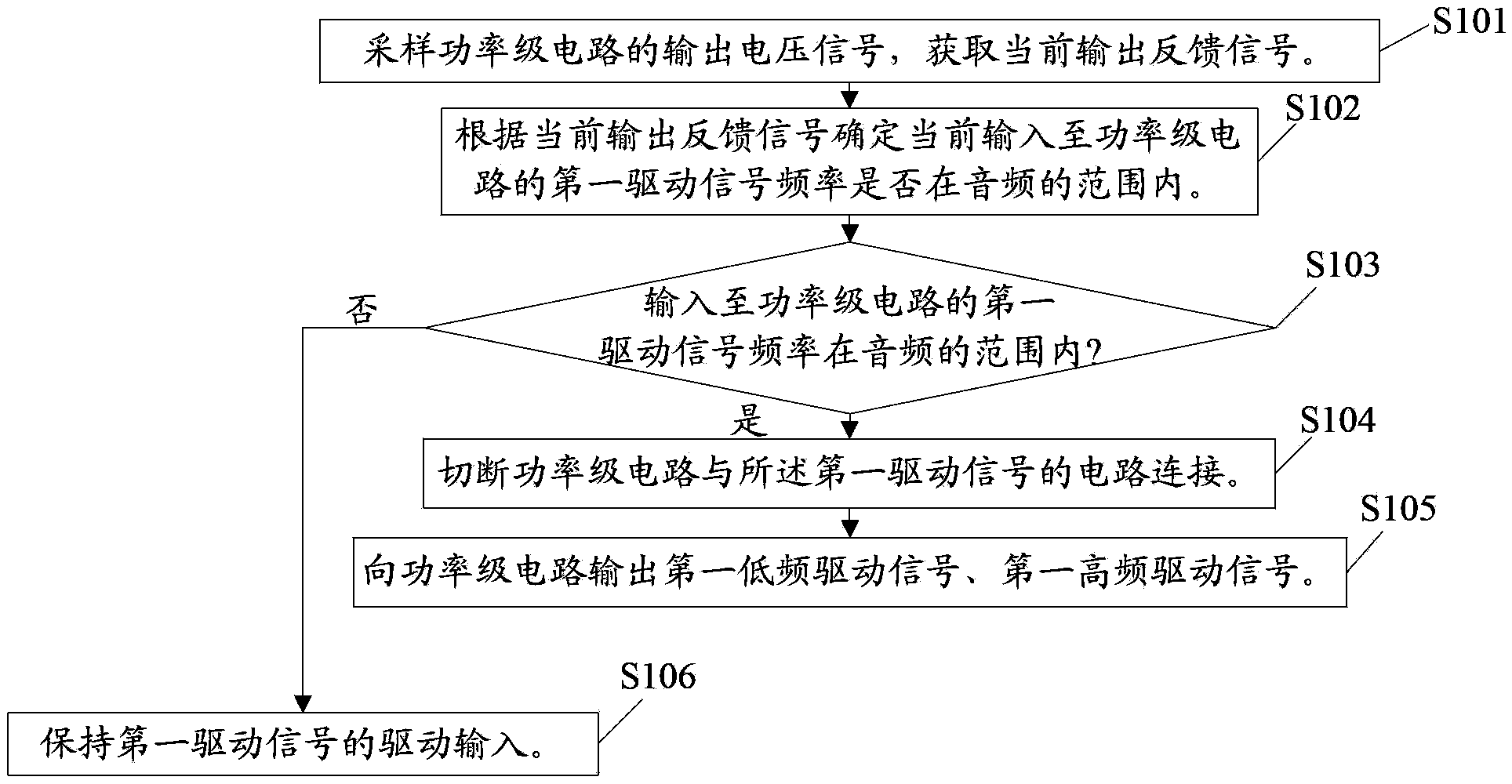

[0158] see figure 1 As shown, the present embodiment provides a noise elimination method, which mainly includes the following steps:

[0159] Step S101: Sampling the output voltage signal of the power stage circuit to obtain the current output feedback signal.

[0160] At the output end of the power stage circuit, the output voltage signal is sampled by the sampling feedback circuit 202, and the current output feedback signal is obtained by the sampling feedback circuit 202, and the output feedback signal changes with the change of the current output voltage signal. for example:

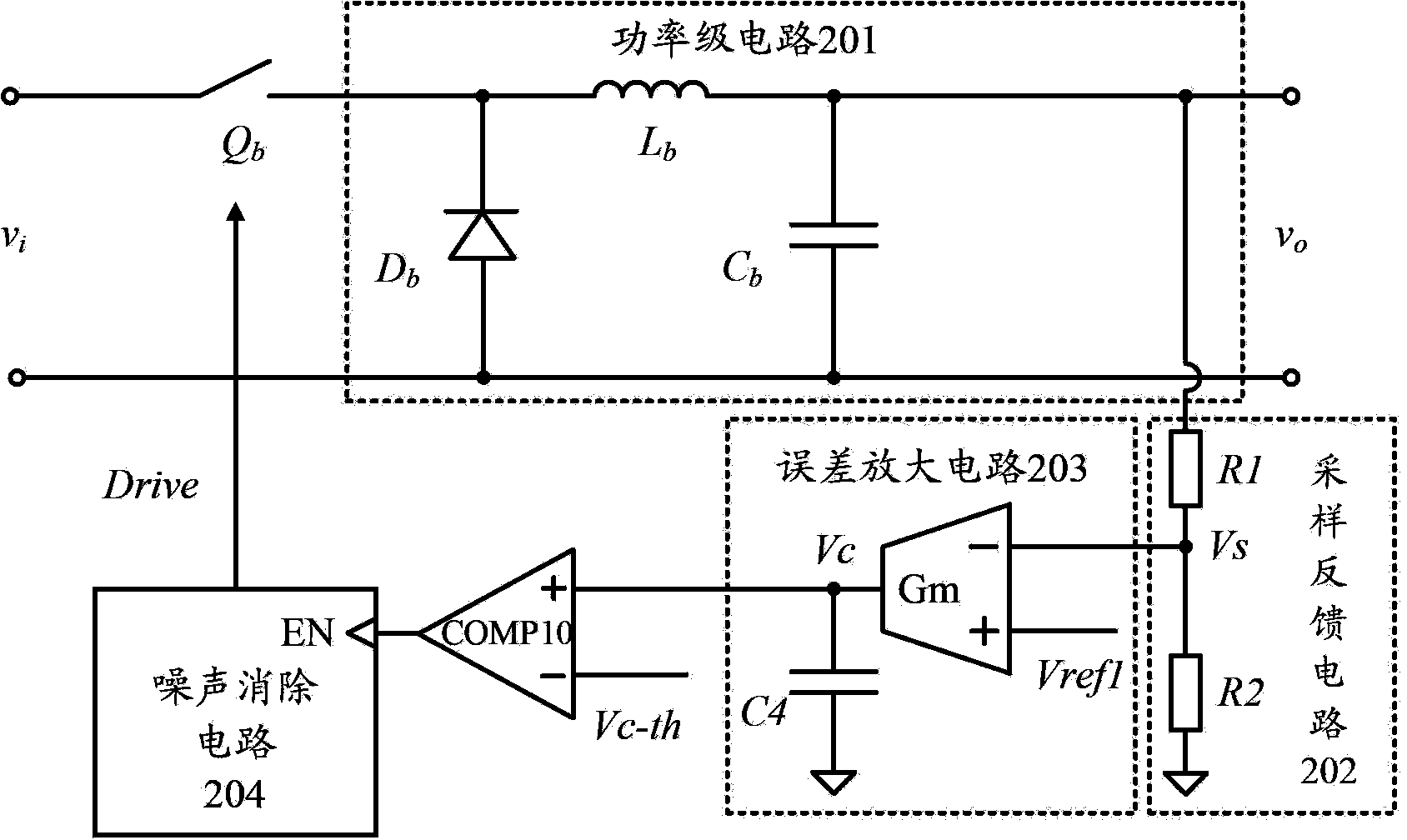

[0161] figure 2 The sampling circuit is connected to the output terminal of the power stage circuit as the sampling feedback circuit 202 through a resistance voltage dividing sampling circuit to obtain an output feedback signal Vs, and the output feedback signal Vs is proportional to the output voltage signal Vo, Vs=Vo*R2 / (R1+R2 ).

[0162] Step S102: Determine whether the frequency of the first...

Embodiment 2

[0185] The only difference between this embodiment and embodiment 1 is:

[0186] As an illustration of this embodiment, the first low-frequency drive signal f_Lq that is input to the power stage circuit and is lower than the audio frequency lower limit can be obtained, but not limited to, using the following technical solutions, which mainly include the following steps:

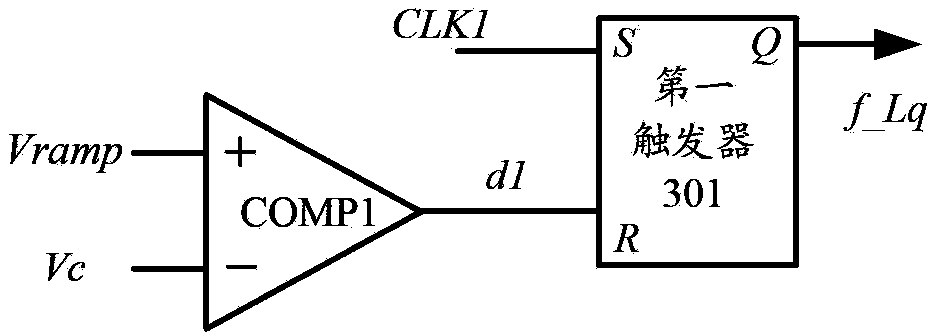

[0187] Step S1051: Comparing the output feedback error signal with the low-frequency reference ramp voltage, and outputting a first-level signal whose frequency is lower than the audio frequency lower limit.

[0188] In this embodiment, the low-frequency reference ramp voltage can be predetermined as: the output feedback voltage when the frequency of the driving signal of the power stage circuit is a preset frequency lower than the audio frequency lower limit, denoted as Vramp. For example, but not limited to, the corresponding output voltage signal when the driving frequency is 10 Hz can be set as the low-fr...

Embodiment 3

[0197] The only difference between this embodiment and embodiment 1 is:

[0198] As an illustration of this embodiment, the first high-frequency driving signal f_Hq higher than the upper audio frequency limit input to the power stage circuit may be implemented by, but not limited to, a hysteresis method. Obtaining the first high-frequency drive signal f_Hq according to the hysteresis method The technical solution mainly includes the following steps:

[0199] Step S301: Compare the current output feedback signal with the first low-frequency output feedback lower limit, and output a first comparison signal f1.

[0200] Wherein, the first low-frequency output feedback lower limit is preset as a minimum value that can represent the output feedback signal.

[0201] The lower limit of the first low frequency output feedback can be set as, but not limited to: when the frequency of the drive signal of the power stage circuit is lower than the first low frequency of the audio frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com