Channel structure for guaranteeing flow rate

A technology of flow channel and flow rate, which is applied in the field of product mold structure, can solve the problems of slow injection molding speed, bubbles, and easy mixing of air into materials, so as to achieve the effect of ensuring speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

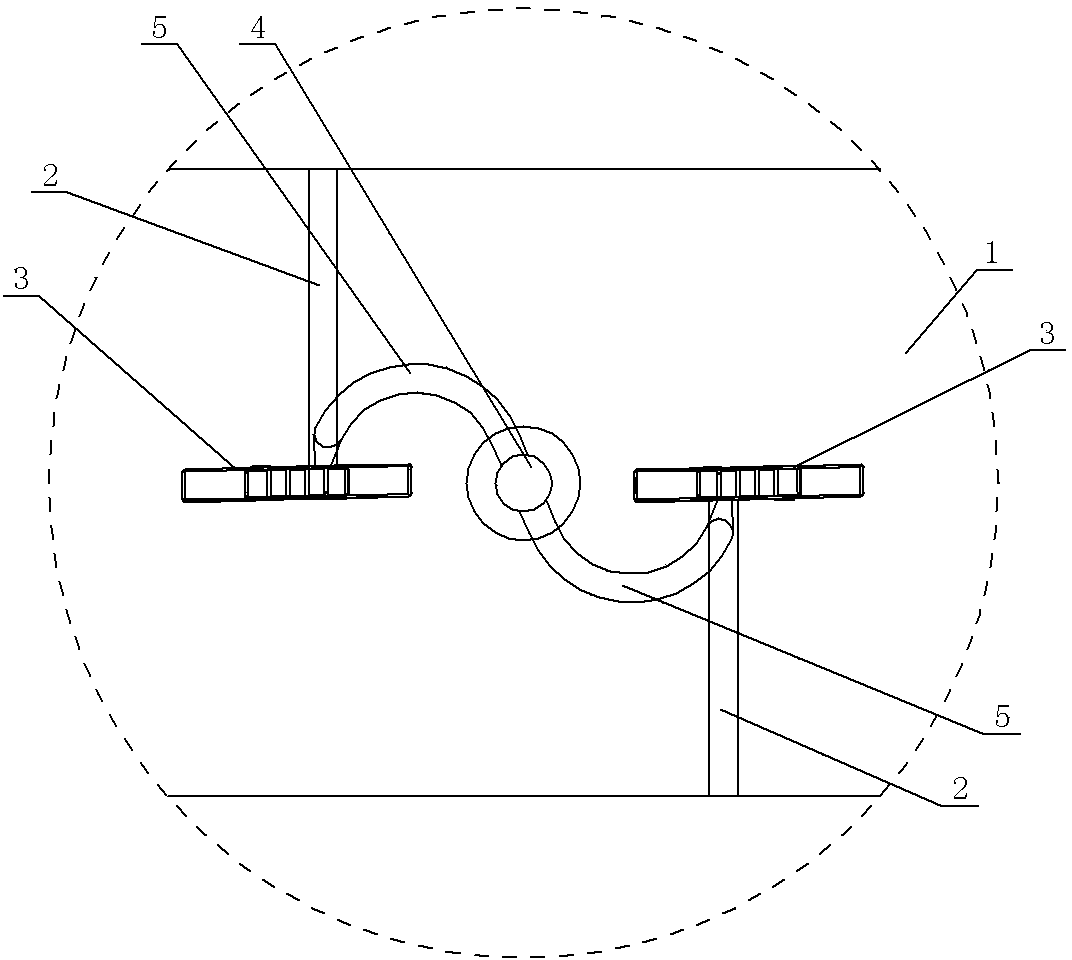

[0007] See figure 1 , which includes a front mold 1, a rear mold (not shown in the figure, which belongs to the existing mature structure), an insert 2, two cavities 3 between the front mold 1, the rear mold, and the insert 2, and a vertical flow channel 4 The lower part of the horizontal flow channel is connected to the horizontal flow channel, and the horizontal flow channel is specifically an arc-shaped flow channel 5. The lower part of the vertical flow channel 4 is respectively connected to the inlets of the circular-arc-shaped flow channels 5 on both sides, and the outlet of the arc-shaped flow channel 5 is connected to the corresponding Cavity 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com