Tai Chi moving infiltration furnace and use method thereof

A technology of taiji and penetrating agent, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as uneven distribution, waste of resources, and dangerous operation, so as to ensure fluidity and purity, prevent The heat is dissipated in the air and the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

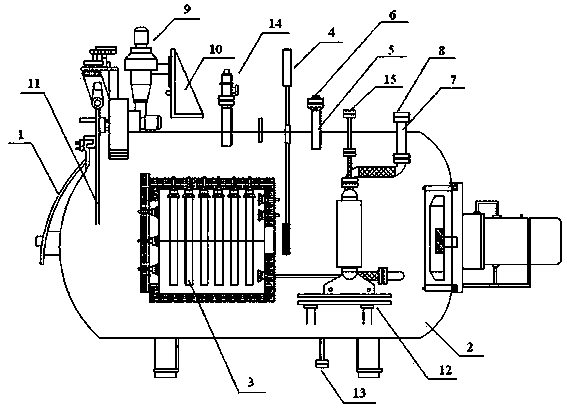

[0014] Attached below figure 1 , A detailed description of the present invention.

[0015] This Tai Chi migration furnace includes a barrel-shaped shell, one end of the shell is fully enclosed, and the other end is installed with a quick-opening sealing structure flange as the furnace door 1. The shell is a barrel-shaped inner cavity, and the inner cavity is installed with a high temperature resistance above 1000 ℃ In the insulation layer, a cylindrical migration cavity 2 is installed in the insulation layer, and a movable guide rail is installed at the bottom of the migration cavity 2 to push in and push out the substrate blank into and out of the furnace door 1.

[0016] A heating device 3 is hung on the inner wall of the migration cavity 2. The heating device 3 can be a far-infrared heating plate or an electric heating tube or plate. The temperature adjustment handle 4 is used to adjust and control the temperature. The heating device 3 is laid with a circulating water pipe and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com