Combined automatic v-cutting machine for circuit board processing

A circuit board and combined technology, which is applied in the field of combined automatic V-cutting machines for circuit board processing, can solve the problems of low work efficiency, high labor intensity of staff, and adverse effects on the health of operators, so as to reduce labor intensity , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

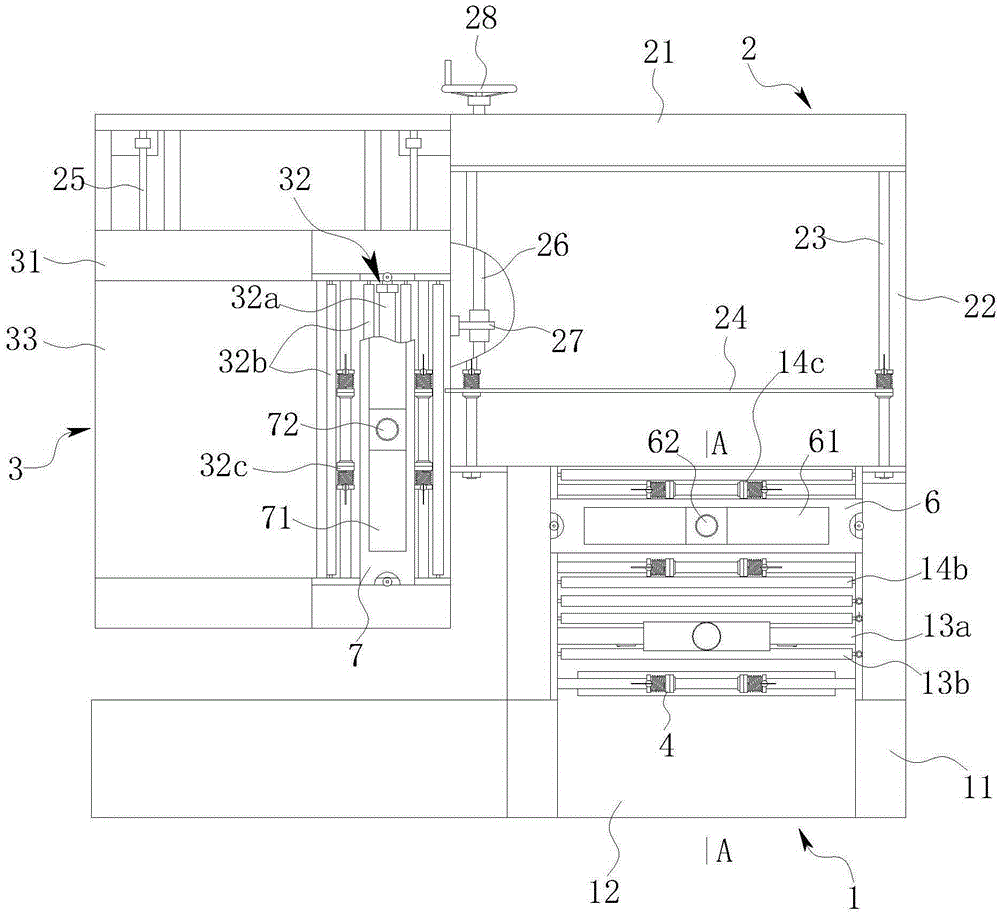

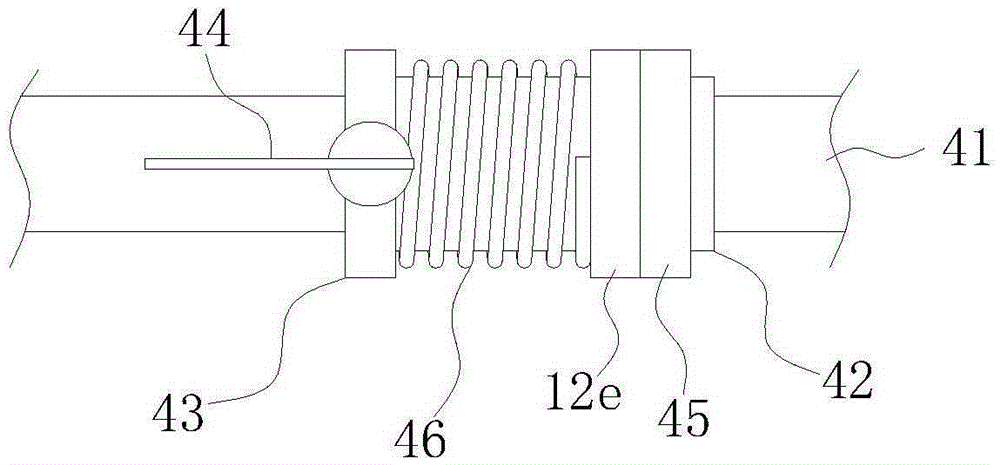

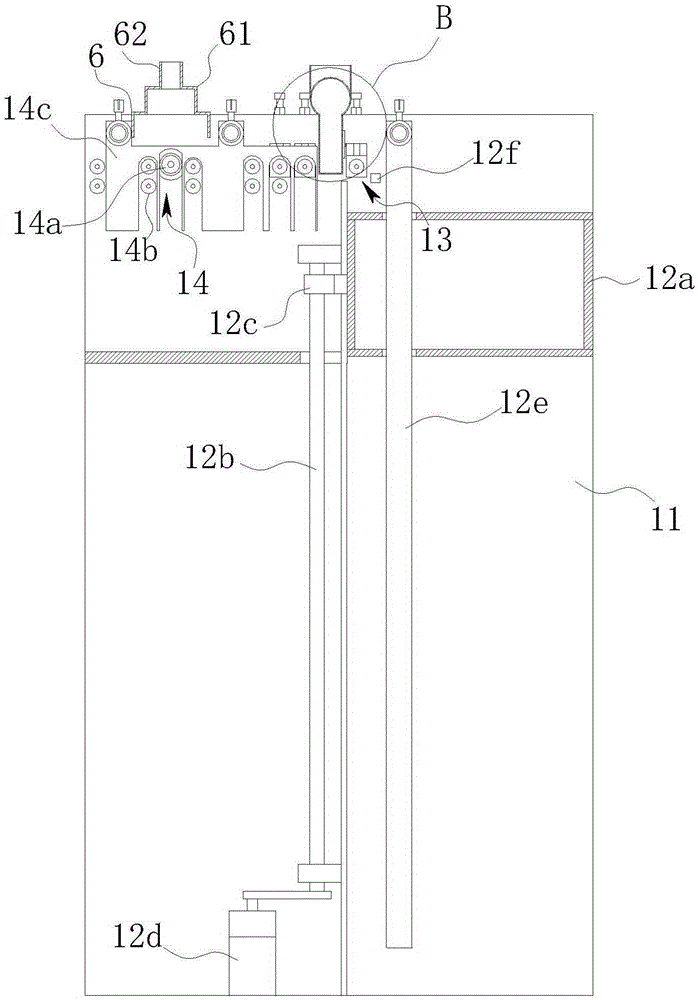

[0026] refer to figure 1 and image 3 As shown, a combined automatic V-cutting machine for circuit board processing of the present invention, the V-cutting machine consists of a longitudinal cutting unit 1, a transverse conveying mechanism 2 arranged at the delivery end of the longitudinal cutting unit 1, and is connected to the transverse conveying mechanism 2 to output The horizontal cutting unit 3 at the end is composed of control terminals; the control terminals are respectively connected to the longitudinal cutting unit 1, the transverse conveying mechanism 2 and the transverse cutting unit 3 circuits; the longitudinal cutting unit 1 and the transverse cutting unit 3 cooperate to cut the four sides of the circuit board Carry out automatic cutting; the longitudinal cutting unit 1 is mainly composed of a longitudinal cutting machine 11, a lifting board feeding mechanism 12 arranged on the front side of the longitudinal cutting board 11, and a negative pressure suction board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com