Manufacturing method of exposure glass micro-sphere reflective membrane capable of reflecting colorful light

A technology of glass microspheres and production methods, applied in chemical instruments and methods, glass/slag layered products, optics, etc., can solve the problem that reflective materials cannot reflect colored light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

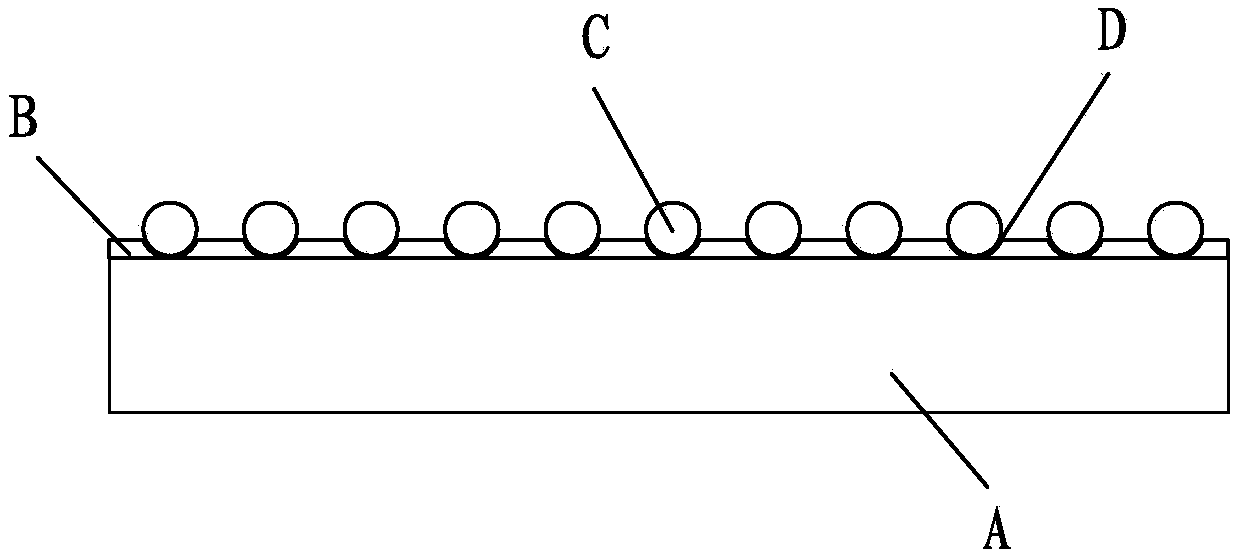

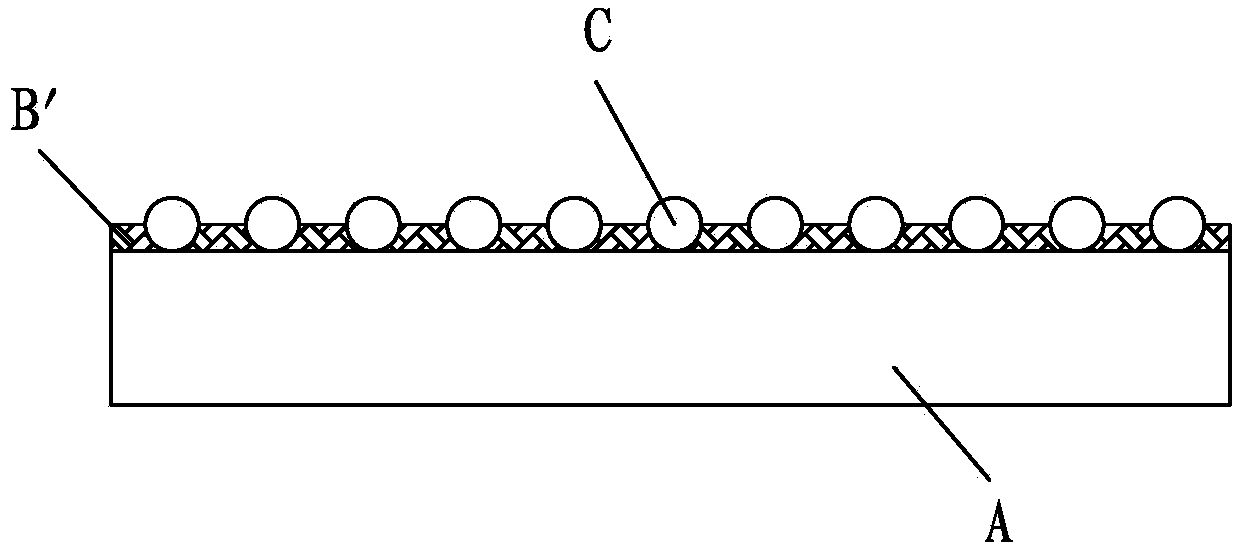

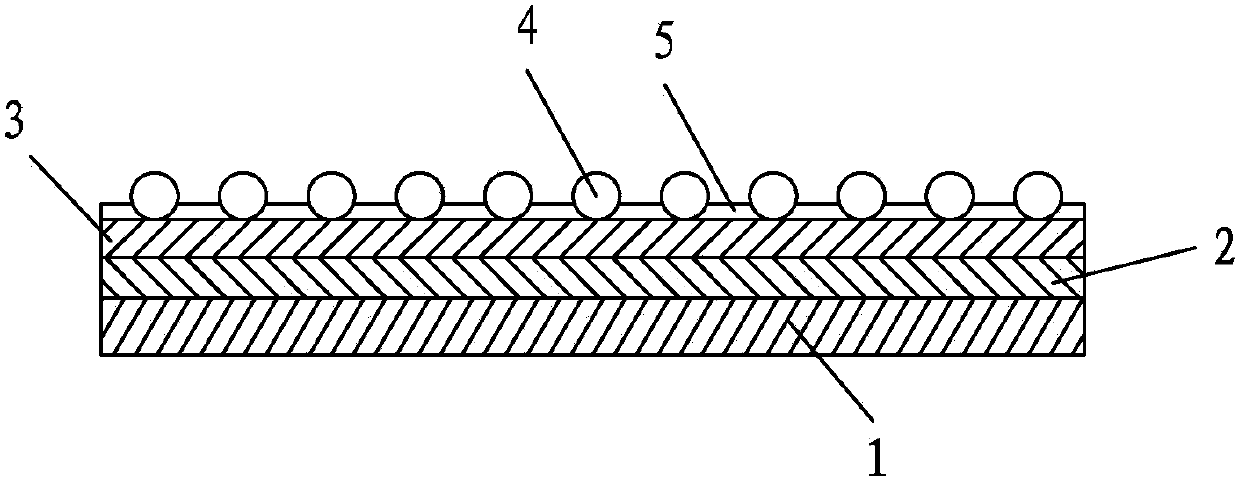

[0035] Example: see image 3 , an exposed glass bead reflective film capable of reflecting colored light, comprising a base material 1, a reflective layer 2, a transparent color layer 3 and a plurality of glass bead convex mirrors 4, the base material 1 is provided with a reflective layer 2 and a transparent The color layer 3 can also be pressed with radium color lines on the transparent color layer as required, and a number of glass bead convex mirrors 4 are planted on the transparent color layer 3 through the transparent adhesive layer 5, and each glass bead convex mirror 4 penetrates the The transparent adhesive layer 5 is in point contact with the upper plane of the transparent color layer 3 .

[0036] In the present invention, the refractive index of the glass bead convex mirror 4 is between 1.90-1.93. The transparent bonding layer 5 between adjacent glass bead convex mirrors 4 is a plane with equal thickness, and its refractive index is between 1.45-1.55. Transparent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com