Manufacturing method of glass bead reflective product reflecting colored light

A technology of glass microbeads and production methods, applied in optics, optical components, instruments, etc., can solve problems such as poor reflection effects, achieve rich patterns, easy control of thickness, and reduce nighttime accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

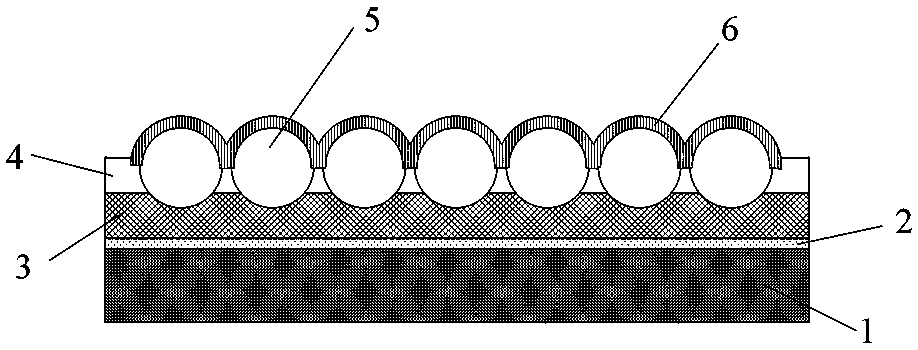

[0018] Example: see figure 1 , a glass bead reflective product that reflects colored light, a resin layer 2, a reflective layer 3, a glass bead convex mirror 5 and a transparent color layer 6 are sequentially arranged on a base material 1; wherein the reflective layer 3 is bonded transparently Layer 4 is planted with a glass bead convex mirror 5, and the glass bead convex mirror 5 penetrates through the transparent adhesive layer 4 and embeds a part into the reflective layer 3, and the transparent color layer 6 is directly covered on the glass bead convex mirror 5. The lower surface is in hemispherical contact with the glass bead convex mirror 5 .

[0019] In the present invention, the refractive index of the glass bead convex mirror 5 is 1.93±0.005. The transparent adhesive layer 4 is acrylic resin or PU resin. The transparent color layer 6 is processed into a hemispherical surface layer by transparent resin and pigments therein, the pigments are nano pigments, and the tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com