Lifting point of plate-type traction shell flange

A cylinder flange and plate type technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of deformation, large local stress of equipment, etc., and achieve the effect of reducing bending, good stress state, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

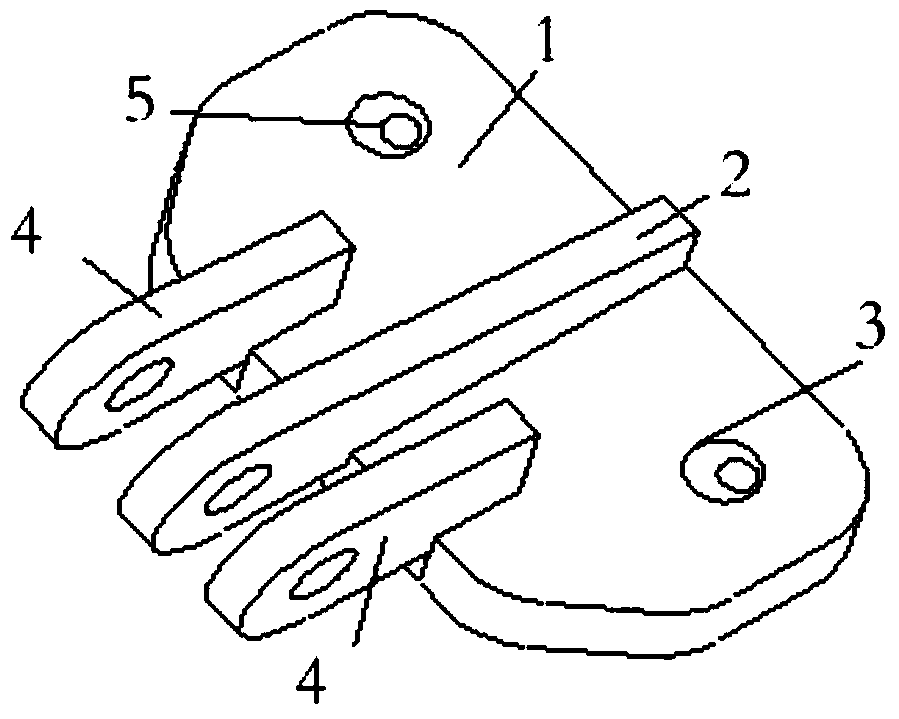

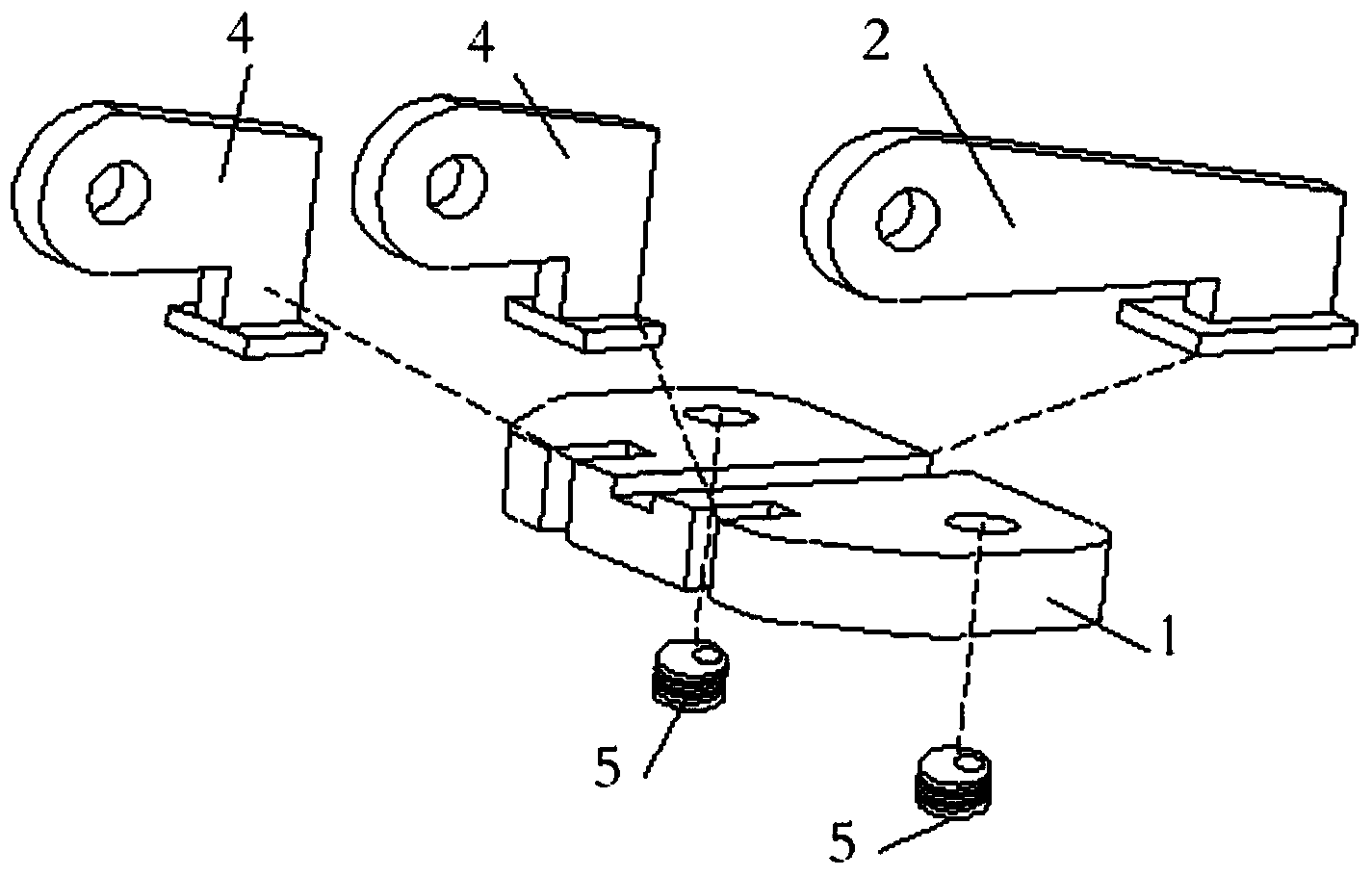

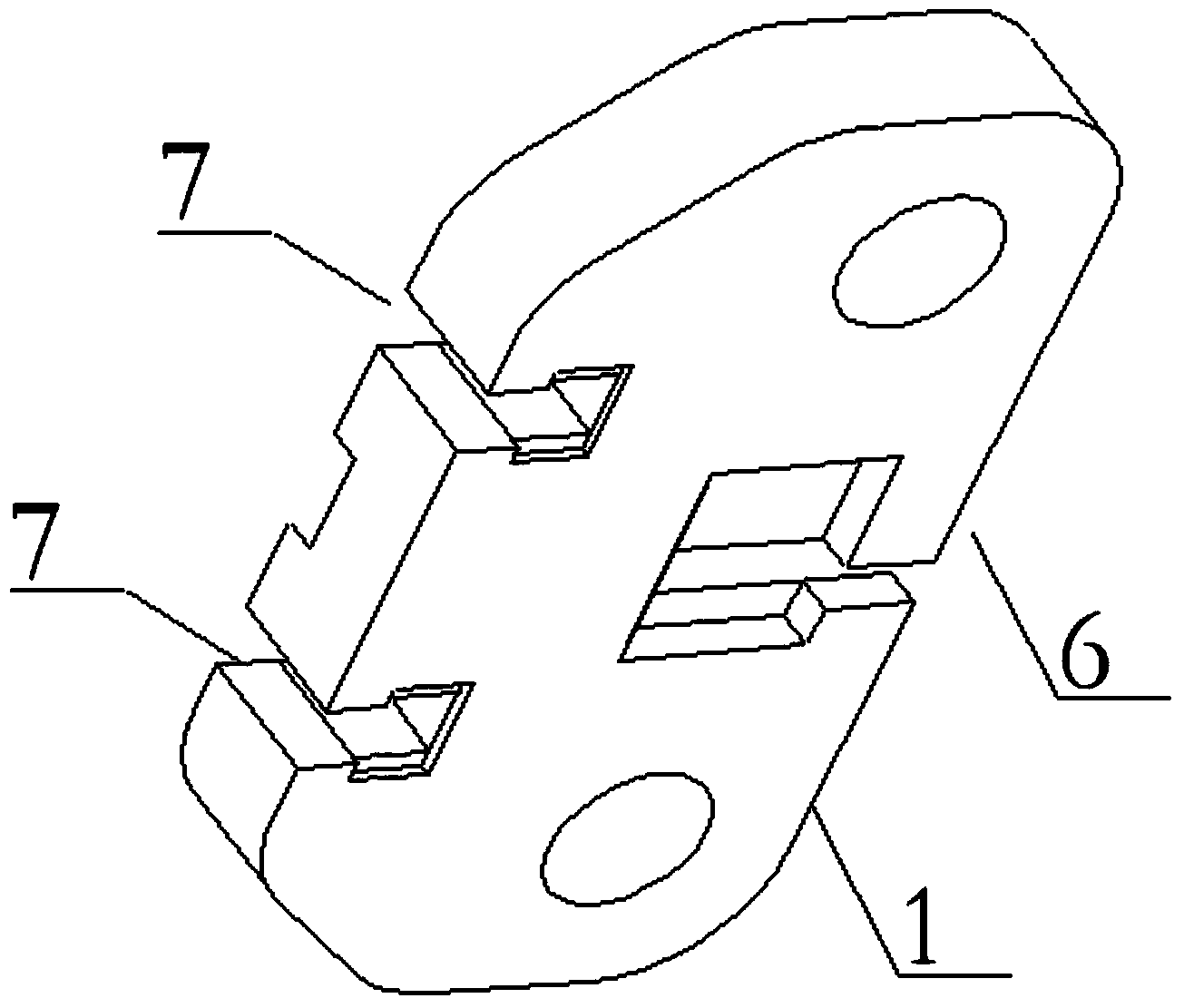

[0024] Such as figure 1 — image 3 As shown, the present invention includes: a hanging point connecting plate 1 arranged at the bottom, a traction eye plate 2 vertically fixed on the lifting point connecting plate 1, wherein the hanging point connecting plate 1 is provided with several threaded holes 3, and the threaded holes 3 is installed with a threaded bushing 5 by threaded connection; the middle part of the hanging point connecting plate 4 is also provided with a stepped groove 6 from one end of the hanging point connecting plate 4 to the other end, and the traction eye plate 2 is clamped on the hanging point connecting plate 4. In the stepped groove 6 of the plate 4; one side of the hanging point connecting plate 4 is provided with several stepped grooves 7, and the stepped grooves 7 are symmetrically arranged on both sides of the stepped groove 6; Strengthen the eye panel4.

[0025] The above-mentioned traction eye plate 2 is an L-shaped structure, one end of the L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com