Engine balance shaft

A balance shaft and engine technology, applied in the direction of inertial force compensation, etc., can solve problems such as the inability to change the balance rate, poor engine operation, and failure of the balance shaft, and achieve a strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

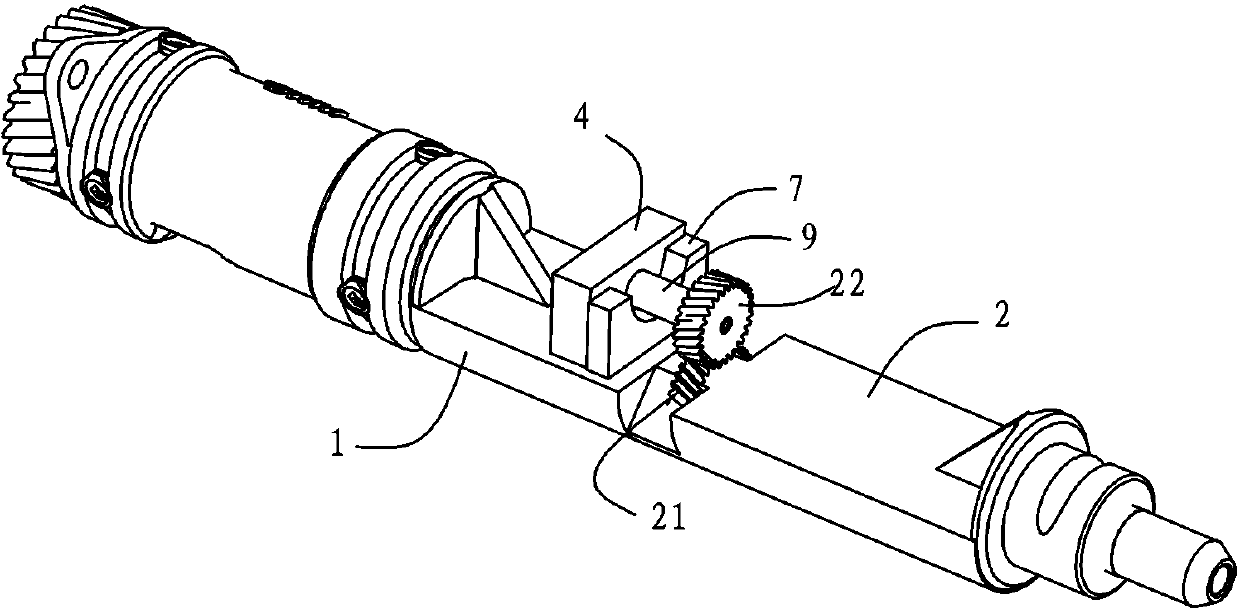

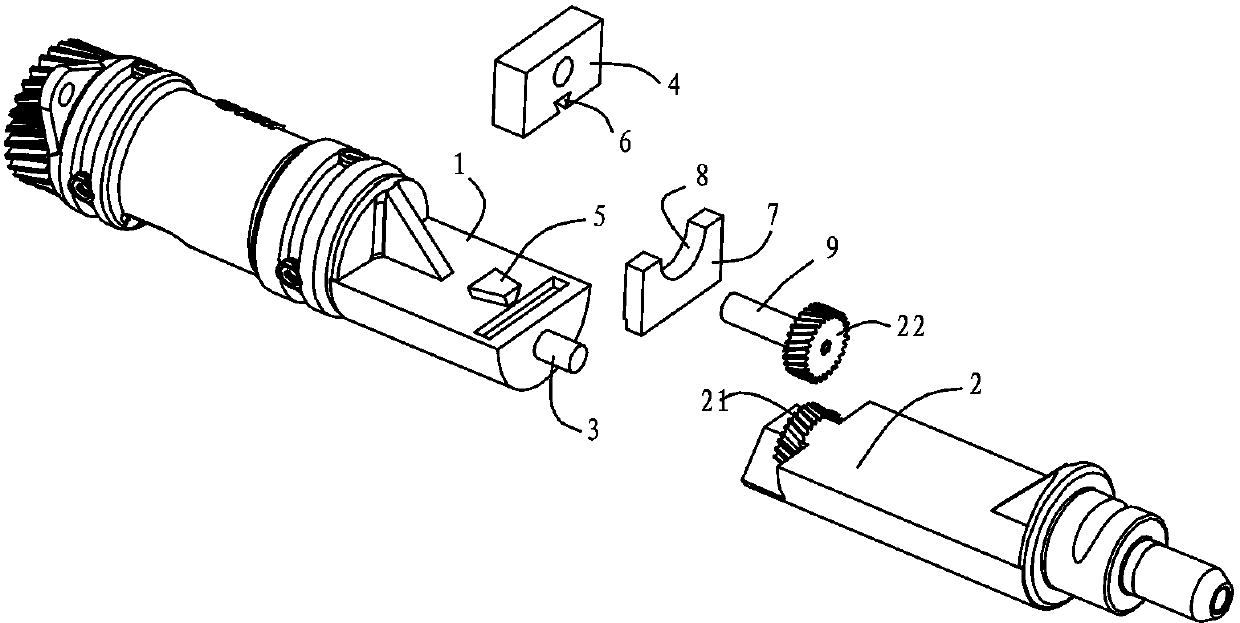

[0016] Depend on figure 1 combine figure 2 As shown, the present embodiment relates to a balance shaft of an engine, which has a first balance weight 1 and a second balance weight 2 whose mass is greater than that of the first balance weight 1, and the main body cross-sectional shapes of the first balance weight 1 and the second balance weight 2 are semicircular, both figure 1 The upper surface of the shown state is a plane. On the end face of the first balance weight 1 opposite to the second balance weight 2, a rotating shaft 3 is fixed. Correspondingly, the second balance weight 2 is provided with a diameter slightly larger than the diameter of the rotating shaft 3, not shown in the figure. The hole shown, in this way, when the rotating shaft 3 is inserted into the hole, the connection between the first balance weight 1 and the second balance weight 2 is realized, and the two can rotate relative to the rotating shaft 3 as the axis, and the connected second balance weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com