A multi-level super-slip structure, a device with the structure and a method for forming the same

An ultra-slip, basic structure technology, applied in building elements, gaseous chemical plating, coatings, etc., can solve problems such as unrealized, large-scale single-crystal materials difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

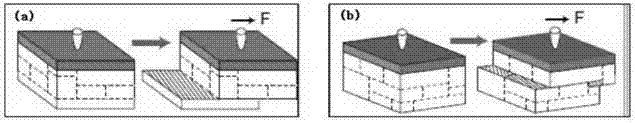

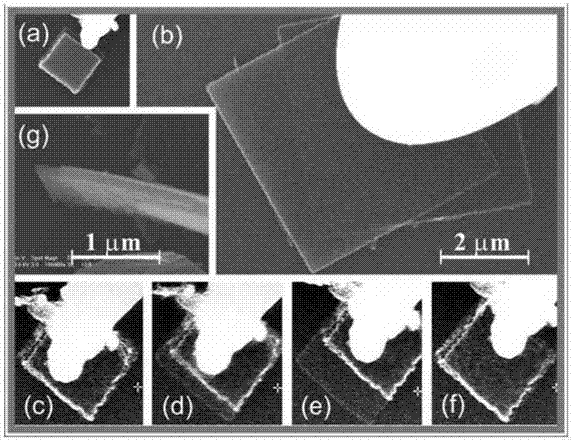

Method used

Image

Examples

no. 1 example

[0049] The first embodiment according to the present invention has been introduced above, and the method for manufacturing the supersmooth basic structure will be described in detail below.

[0050] Such as Figure 10-15 described, including the following steps:

[0051] In step 1, a substrate 103 is provided, and the substrate can be graphite, such as a highly oriented pyrolytic graphite (HOPG) substrate or natural graphite, or the internal atoms of the substrate material may locally have incommensurate contacts between layers. Preferably, the graphite substrate should also be peeled off the skin, such as sticking the graphite surface with an adhesive tape and then peeling off the tape to peel off the skin, or cutting the graphite from the side with a thin blade.

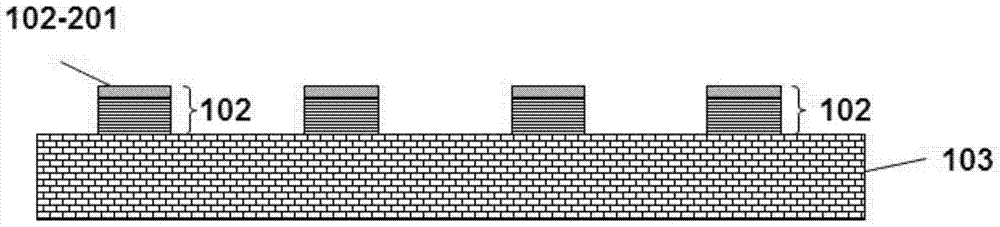

[0052] Then, in step 2, an island structure is prepared and brought into a state of connecting the island structure to the substrate. Specifically, the following steps may be included: step 2-1, covering the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com