An LED packaging structure with an asymmetric rectangular light spot

A technology of LED packaging and rectangular spot, applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of light energy waste, increase density, increase road construction costs, etc., achieve uniform brightness and improve overall light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

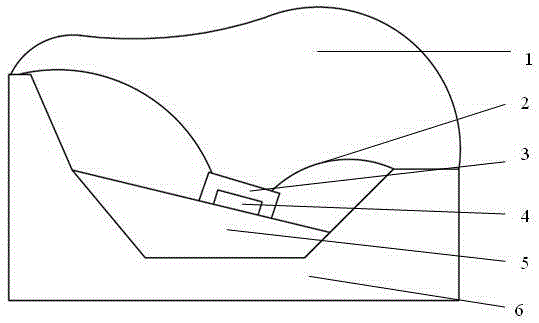

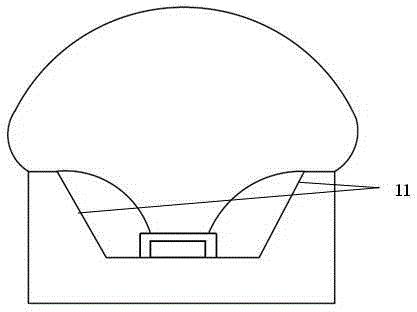

[0025] Such as Figure 1 to Figure 4 As shown, an LED packaging structure with an asymmetric rectangular spot includes a heat dissipation aluminum groove 6 with a reflective surface, a transparent heat conduction ceramic 5 arranged at the bottom of the groove of the heat dissipation aluminum groove 6, and the transparent heat conduction ceramic 5 is provided with embedded Type copper foil, the embedded copper foil is connected to the LED chip 4 mounted on the transparent heat-conducting ceramics, the LED chip 4 is evenly sprayed with phosphor powder 3, and the opening of the heat dissipation aluminum groove 6 is potted and set There is a transparent silica gel 1, and the LED chip 4 is connected with the electrode connecting gold wire 2. Considering that the height of the street lights is 10 meters, the spacing is 50 meters, and there are 4 lanes, each lane is 3.75 meters wide. The upper end of the transparent heat-conducting ceramic 5 is provided with an inclined surface 8, an...

Embodiment 2

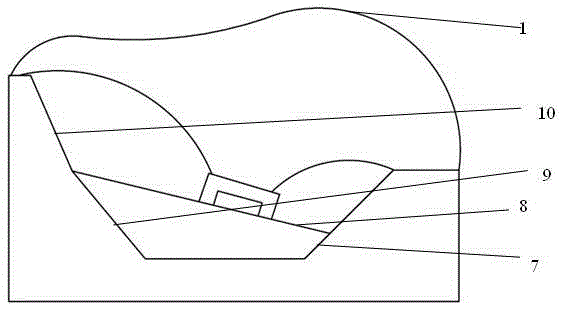

[0038] In this embodiment, except the following features, all the other features are the same as in Embodiment 1:

[0039] The maximum outgoing angle on the right side of the present embodiment is 61 degrees, the angle between the upper reflection surface 10 on the left side and the bottom plane of the groove is 82.8 degrees, and the angle between the reflection surface 7 on the right side and the bottom plane of the groove is 32 degrees. The length of the right side of the illuminated rectangular spot is shortened to 18 meters, and the left side is still about 4 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com