Sample bag

A sample and bag body technology, applied in the preparation of test samples, laboratory utensils, chemical instruments and methods, etc., can solve the problems of inconvenience of carrying, high production cost, complicated operation, etc., and achieve convenient storage and carrying, and low sample pollution , The effect of low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

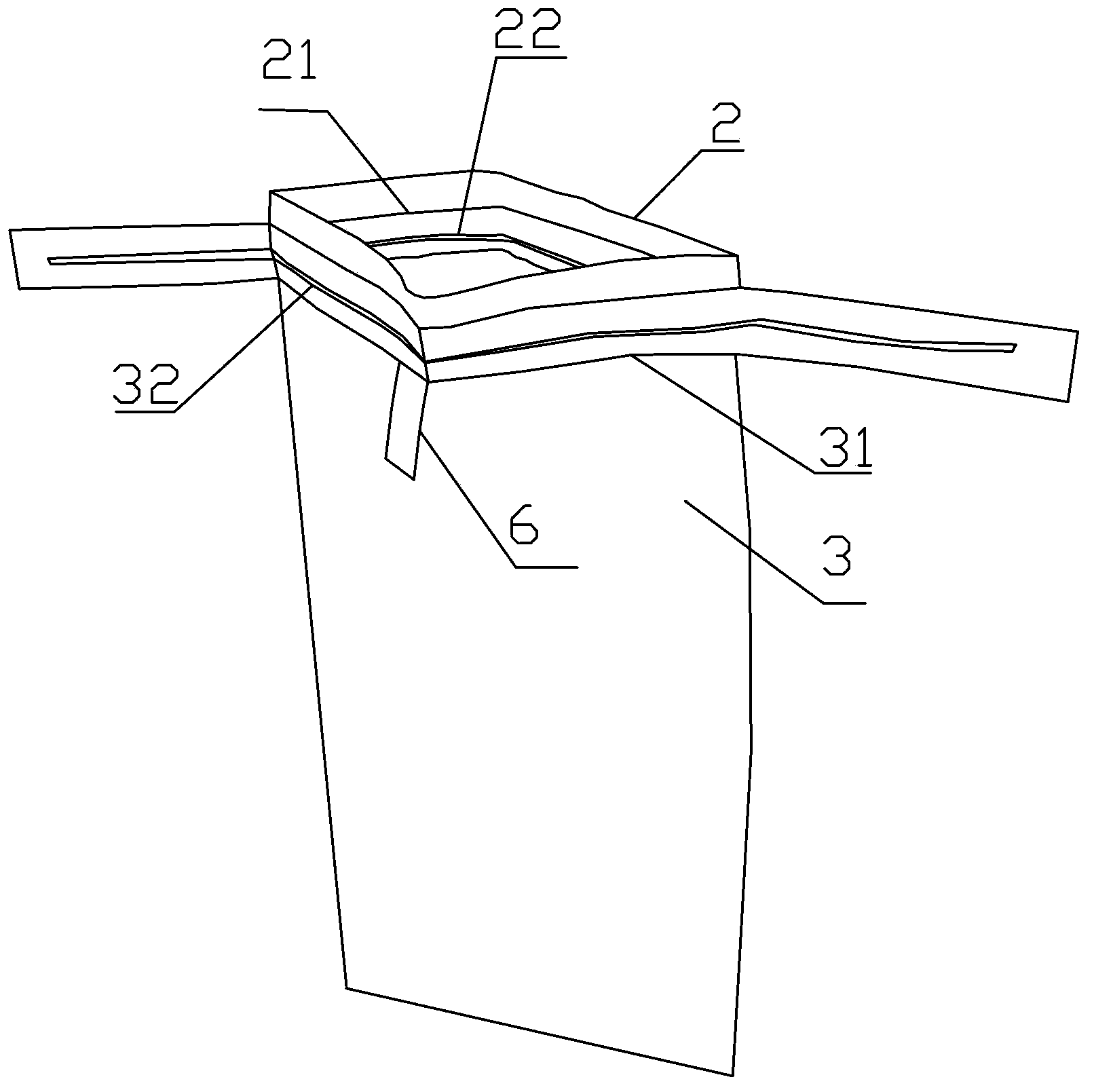

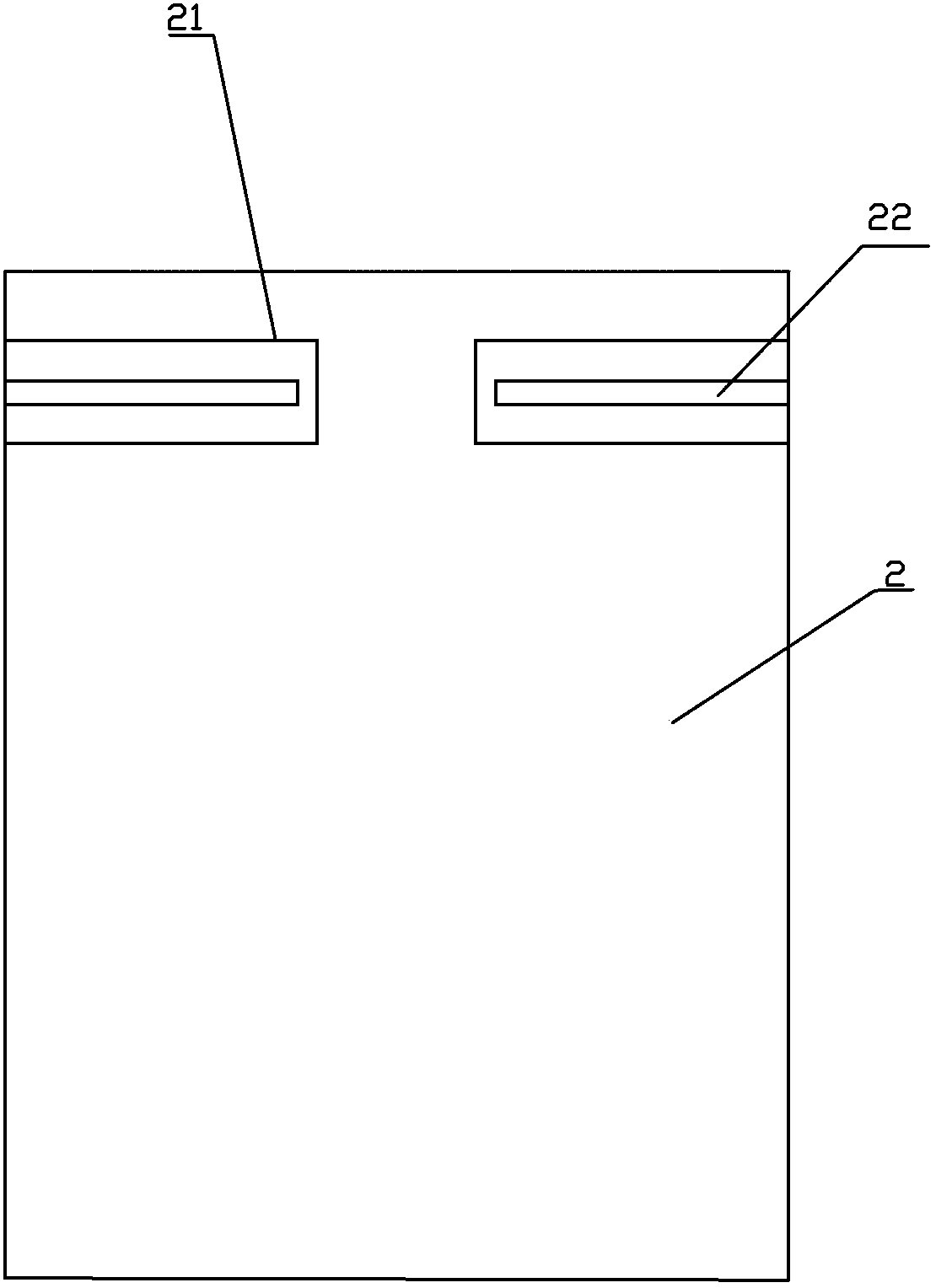

[0021] Embodiment 1: a kind of sample bag, comprises bag body and bag mouth, as figure 1 , 5 As shown, the mouth of the bag is a dotted line seal 4; the bag body contains the first plastic film 2 and the second plastic film 3, the left and right sides of the first plastic film 2 and the second plastic film 3 of the sample bag and The bottom side is a snug fixed connection. A first sealing strip 21 is arranged on the outside of the bag and near the mouth of the bag, the first sealing strip 21 is arranged transversely and is closely fixed to the first plastic film 2; between the first sealing strip 21 and the first plastic film 2 The first metal wire 22 is provided, and the first metal wire 22 is arranged transversely and corresponds to the first sealing strip 21; the second plastic film 3 is respectively provided with a second sealing strip 31 corresponding to the first sealing strip 21 And the second metal wire 32 corresponding to the first metal wire 22, the second sealing ...

Embodiment 2

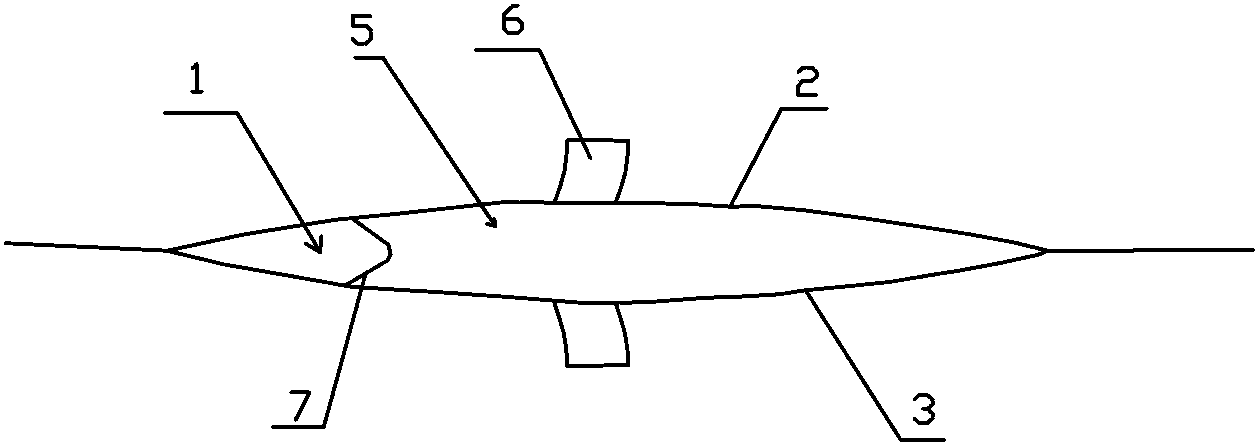

[0024] Embodiment 2: the only difference between embodiment 2 and embodiment 1 is: a kind of sample bag, such as figure 1 , 2 , 3, the left and right sides of the filter cloth 7 and one side of the first plastic film 2 and the second plastic film 3 are closely fixed to each other; the periphery of the filter cloth 7 and the first plastic film 2 and the second plastic film The peripheries of the two plastic films 3 are closely attached to each other and fixed, and one side is reserved as the mouth of the bag, and the space on both sides of the filter cloth 7 is the storage space 5 and the sampling space 1 of the sample bag. Example 2 is the same as Example 1 for the rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com