A die base for improving the service life of the convex and narrow structure in the inner hole of the trimming die

An in-die, concave die technology, applied in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problems of low service life of the convex and narrow structure of the inner hole of the trimming die, etc. To achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

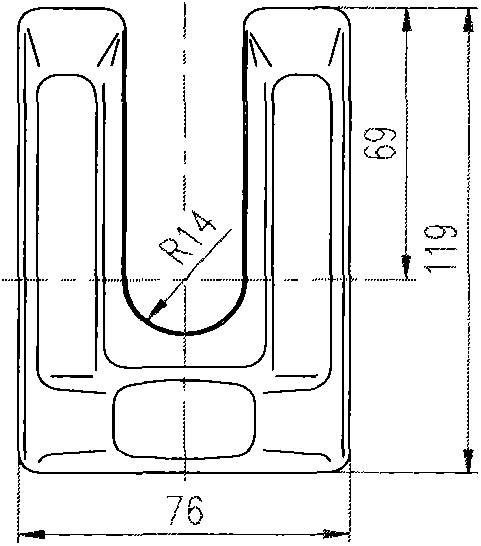

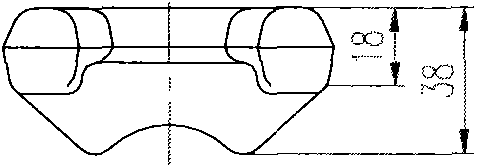

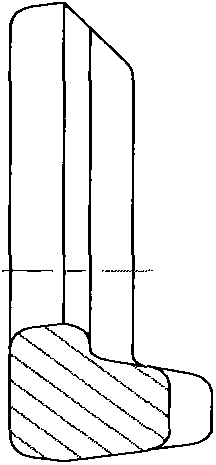

[0021] A kind of die holder (such as Figure 3a and Figure 3b Shown), including three main components of fixed die dovetail 1, support die boss 2 and support boss bottom plate 3.

[0022] The fixed die dovetail 1 is located at the uppermost part in the middle of the mold base (including the positioning bottom surface and one fixed slope on the left and right sides), the supporting die boss 2 is located below the fixed die dovetail 1 in the middle of the mold base, and the support boss bottom plate 3 above the front upper end, the support boss bottom plate 3 is located below the support die boss 2 and at the bottom of the middle of the mold base, the above three main components are integrated structure (compact structure and sufficient strength); the heat treatment hardness of the mold base It is 41~47HRC.

[0023] The length x width x depth x dovetail slope of the fixed die dovetail 1 is 200mm x 200mm x (90-60)mm x 10°, which is the same as Figure 2a and Figure 2b The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com