The convex-concave assembly structure of jaw body and jaw insert

A technology of assembly structure and jaws, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problem of short service life of jaw body and jaw inserts, and it is difficult to fix the assembly jaws. To solve the problems such as mouth inserts, it can achieve the effect of simple fixed installation process, simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

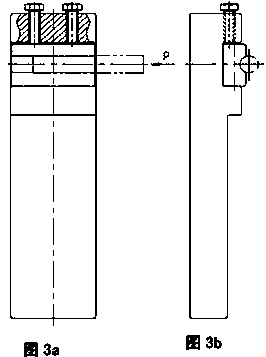

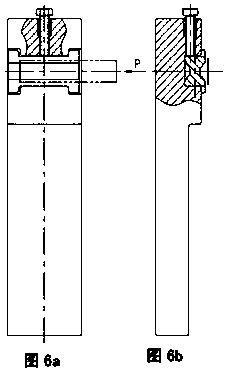

[0027] refer to Figure 6a and Figure 6b As shown, the convex-concave assembly structure of the jaw body and the jaw insert in this embodiment includes three components: the jaw body, the jaw insert and the fine-tuning bolt. For the convex part, the fine-tuning bolt is screwed into the fine-tuning threaded hole 3 and the jaw insert is tightened with a slight force.

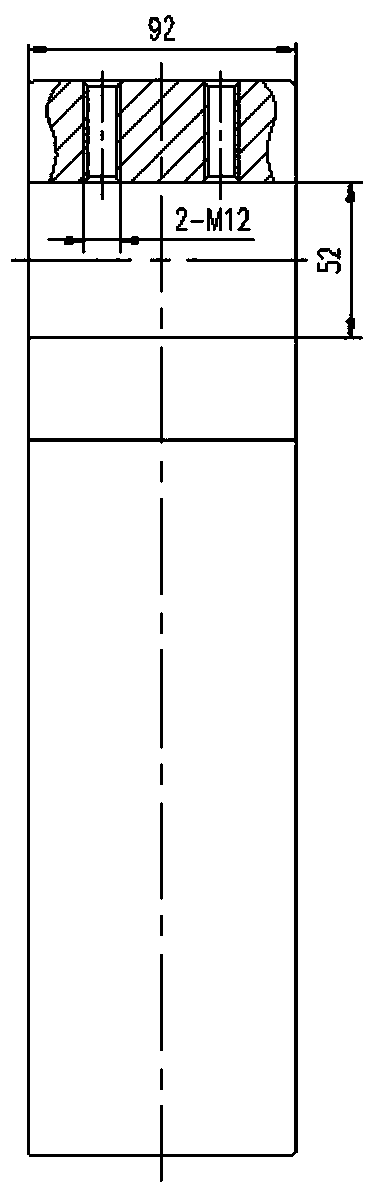

[0028] The jaw body includes three main components: a fixed boss 1, a fixed cavity 2 and a fine-tuning threaded hole 3. The structure is simple and compact, and the strength is sufficient. The fixed boss 1 is located symmetrically in the middle of the fixed cavity 2 of the jaw body. The upper and lower parts of the upper and lower parts are rectangular p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com