Centrifugal fan with axial flow wind direction

A technology of centrifugal fan and axial flow direction, which is applied to the components of pumping devices for elastic fluids, radial flow pumps, non-variable pumps, etc., and can solve the problem of small size, hindering flow field, and setting space restrictions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

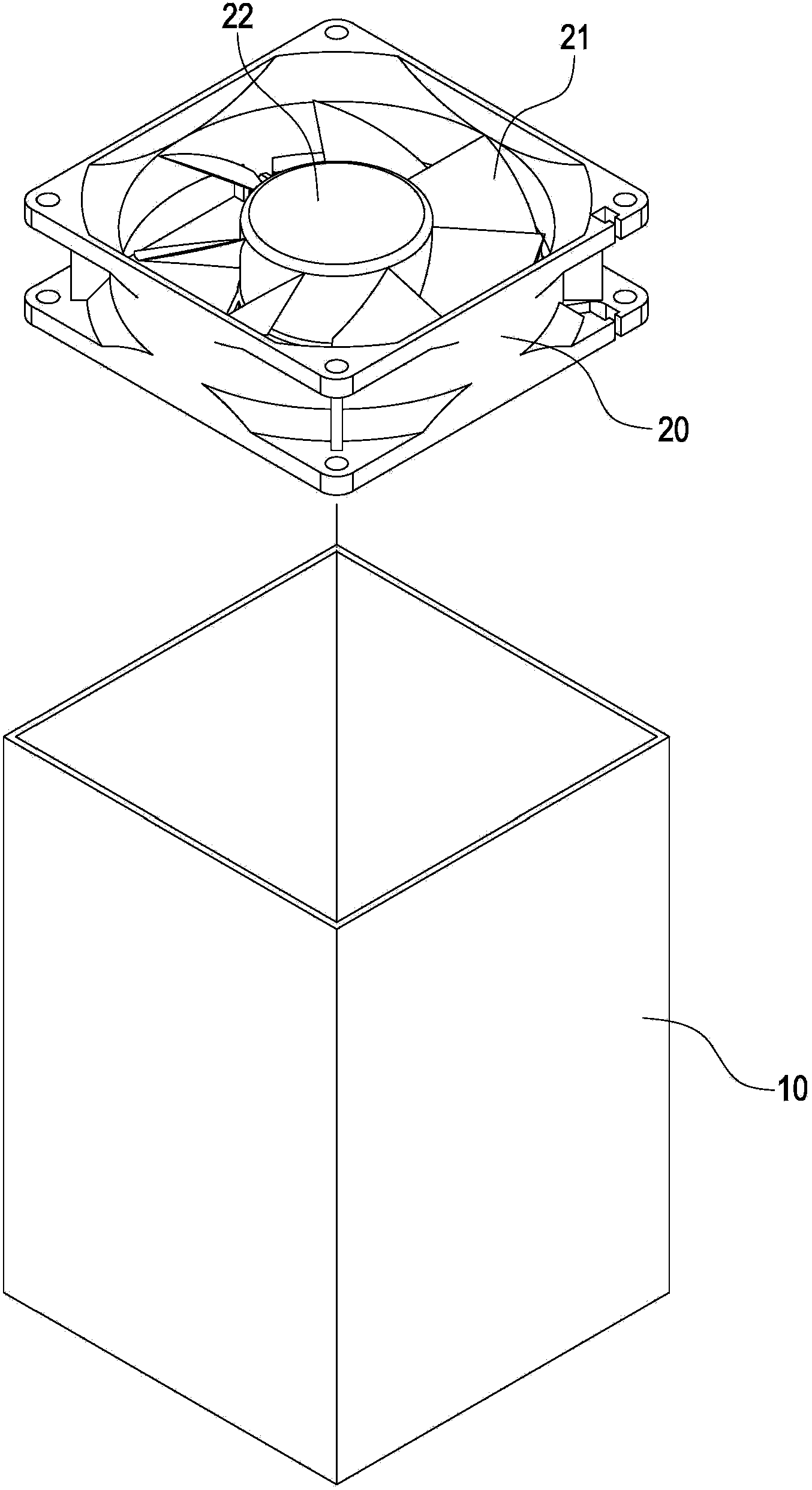

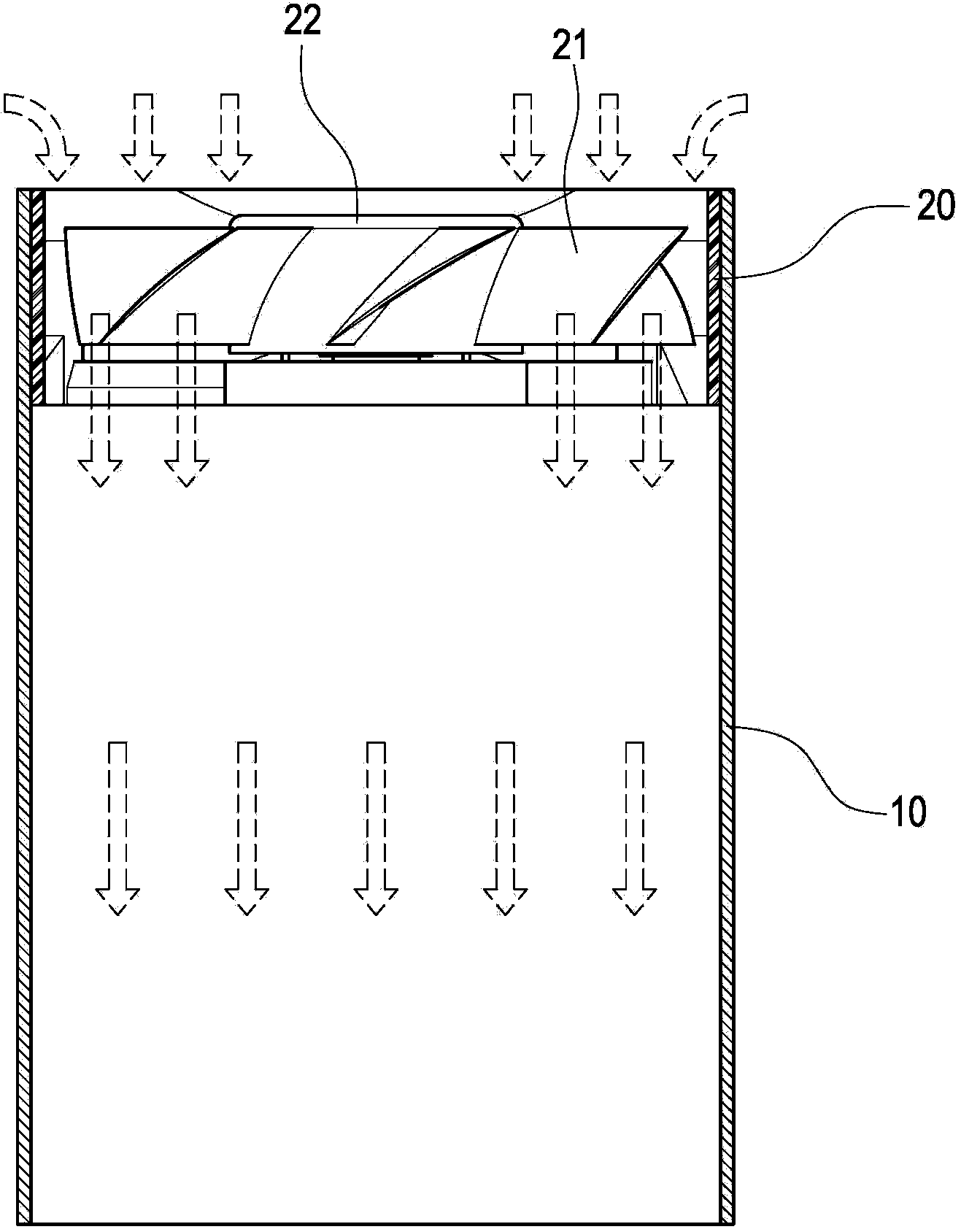

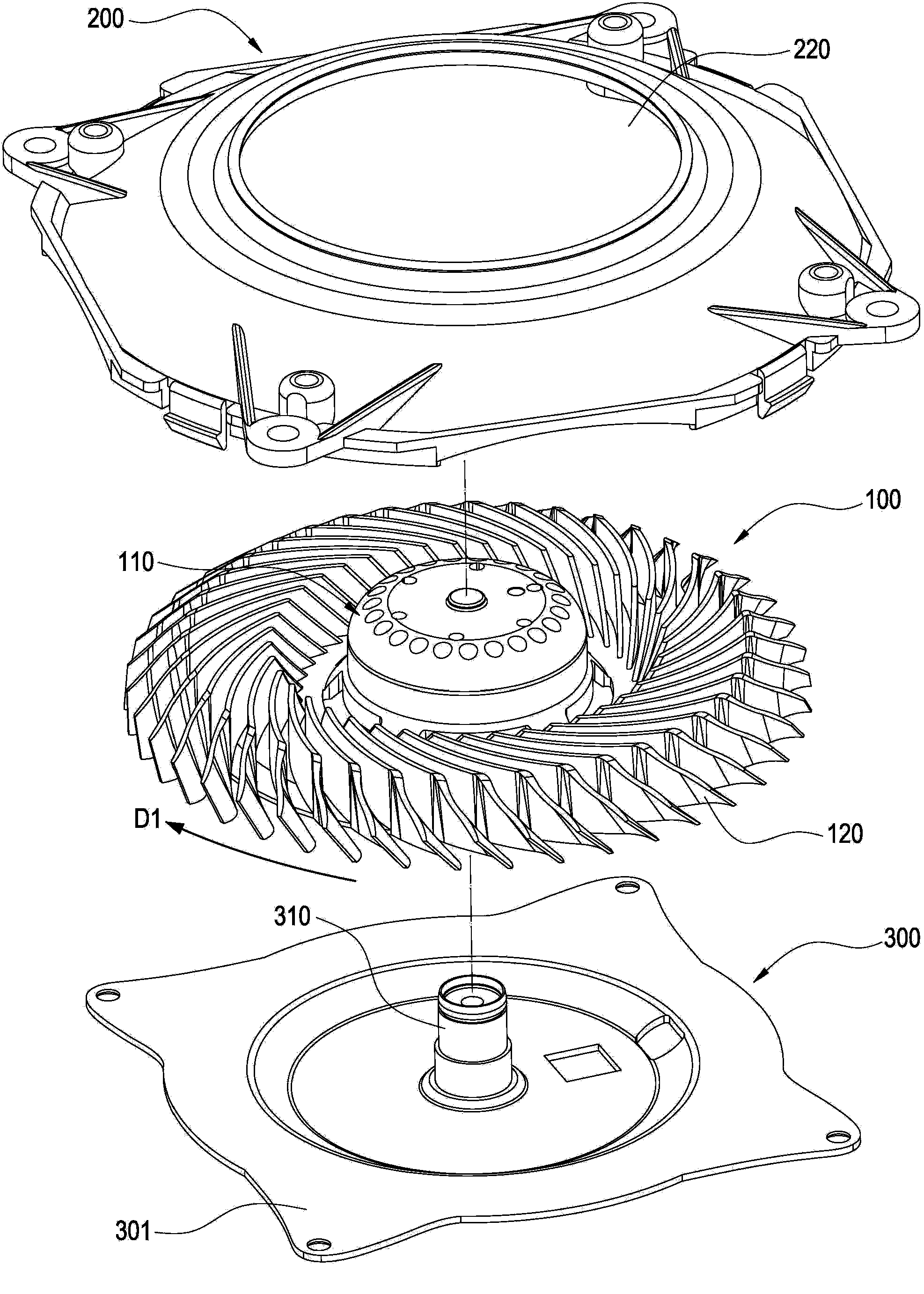

[0051] refer to image 3 and Figure 4 , The first embodiment of the present invention provides a centrifugal fan with an axial flow direction, which includes a centrifugal fan wheel 100 , a casing 200 and a fixing seat 300 .

[0052] refer to Figure 3 to Figure 5 , the centrifugal fan wheel 100 includes a rotating core structure 110 and a plurality of centrifugal fan blades 120 . The rotating core structure 110 includes a fan hub 111 and a bottom plate 113. The fan hub 111 is preferably a cylindrical shell (but the present invention is not limited thereto, for example, the fan hub 111 may also be a conical shell), and the fan hub 111 is preferably a cylindrical shell. The inner side of the hub 111 has a rotating shaft 112, the rotating shaft 112 is preferably arranged along the axial direction of the fan hub 111; the centrifugal fan wheel 100 rotates along the rotating shaft 112 towards a forward rotation direction D1; Along the radial extension of the fan hub 111 (or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com