Tubular sealed lamp

A technique for tubular, tubular envelopes used in tubular enclosed lamps. field, to achieve the effect of overcoming poor contact, stable installation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

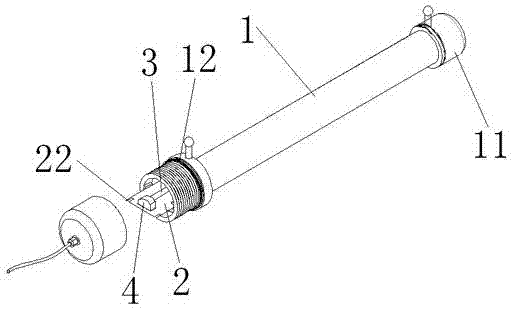

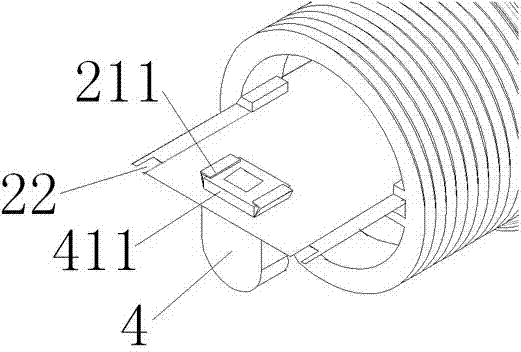

[0028] A tubular enclosed lamp, comprising a transparent tubular shell 1, a base plate 2 installed in the tubular shell and a lamp tube 3 mounted on the base plate, the two ends of the tubular shell are provided with sealing end caps 11, and inside the sealing end caps A sealing ring 12 is provided, and a thinning ring is also provided on the bottom surface of the sealing end cap. Both ends of the strip-shaped substrate 2 are provided with end holes 21, and the back side of the end hole 2 is provided with side wings 211 folded by it. The socket socket 4 is inserted into the port hole 21, and the socket socket 4 includes a seat cover 41, a fixing part arranged in the seat cover and a contact piece electrically connected with the contact on the lamp tube. The seat cover 41 and the fixing part are provided with a lamp tube installation hole corresponding to the side facing the lamp tube 3 , and the bottom of the seat cover 41 is provided with a base 411 . There are protrusions o...

Embodiment 2

[0031] The difference from Embodiment 1 is that Embodiment 2 has side slots on the base 411 on both sides opposite to the side wings 211 . Groove fixed socket 4.

[0032] This embodiment can ensure the full sealing of the lamp, and it is safer to use. The structure of the socket is simple, and the installation with the lamp tube is stable and firm. The socket is fixed by the base and the side of the end hole, which is more secure. Moreover, the installation and disassembly are also convenient, which can overcome the defects of poor contact of the lamp tube and troublesome maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com