Insulation material for solar water heater water tank

A technology for solar water heaters and thermal insulation materials, applied in the field of polyurethane thermal insulation materials, can solve problems such as high production cost, inconvenient installation, fire occurrence, etc., achieve the effect of improving service life and safety performance, solving the problem of dimensional deformation, and ensuring complete sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix 45 parts of isocyanate, 2 parts of catalyst, 35 parts of flame retardant and 18 parts of foaming agent to make component A; mix 80 parts of polymer polyol, 5 parts of glass fiber, 10 parts of anti-aging agent and 5 parts of Mix deionized water evenly to make component B; add 1 part of component A and 1.5 parts of component B into the material tank, stir at high speed for 15 minutes, and mix well; pour the uniformly mixed material into the solar water heater tank to keep warm In the cavity of the layer, the polyurethane insulation layer is obtained after the material is foamed and cured.

Embodiment 2

[0017] Mix 50 parts of isocyanate, 5 parts of catalyst, 25 parts of flame retardant and 20 parts of foaming agent to make component A; mix 85 parts of polymer polyol, 5 parts of glass fiber, 5 parts of anti-aging agent and 5 parts of Mix deionized water evenly to make component B; add 1 part of component A and 1.6 parts of component B into the material tank, stir at high speed for 15 minutes, and mix well; pour the uniformly mixed material into the solar water heater tank to keep warm In the cavity of the layer, the polyurethane insulation layer is obtained after the material is foamed and cured.

Embodiment 3

[0019] Mix 55 parts of isocyanate, 5 parts of catalyst, 25 parts of flame retardant and 15 parts of foaming agent to make component A; mix 90 parts of polymer polyol, 2 parts of catalyst, 5 parts of anti-aging agent and 3 parts of anti-aging agent Mix the ionic water evenly to make component B; add 1 part of component A and 1.8 parts of component B into the material tank, stir at high speed for 15 minutes, and mix well; pour the uniformly mixed material into the insulation layer of the solar water heater tank In the cavity, the polyurethane insulation layer is obtained after the material is foamed and matured.

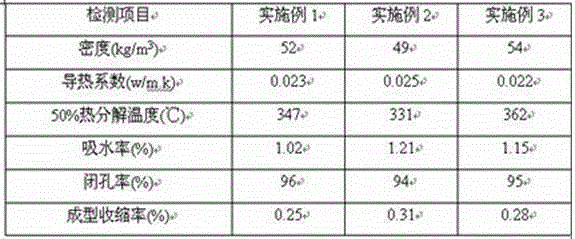

[0020] After testing, the main physical properties of the solar water heater water tank insulation layer material of embodiment 1-3 are as described in table 1:

[0021] Table 1 The main physical performance parameters of solar water heater water tank insulation layer materials

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com