Linear feed structure of machine tool

A linear feed, machine tool technology, used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of reducing the precision of machine tools and unstable quality of processed products, and achieves reduced winding, stable quality, and guaranteed quality. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

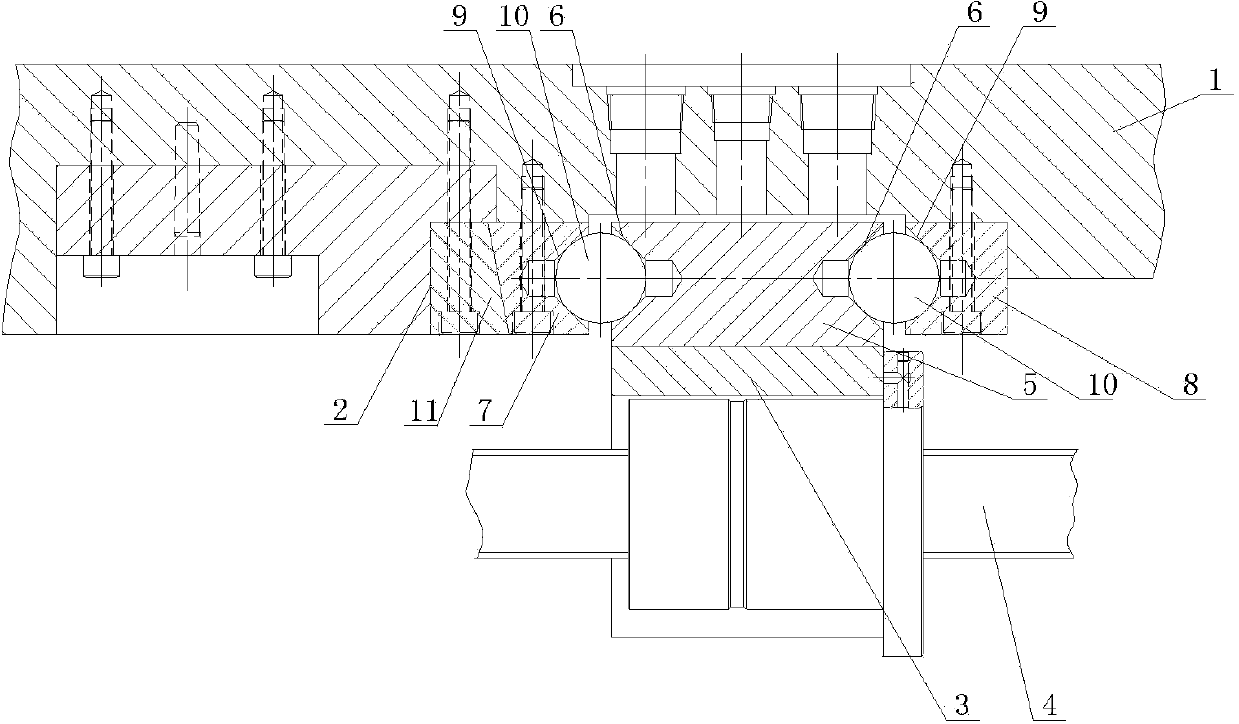

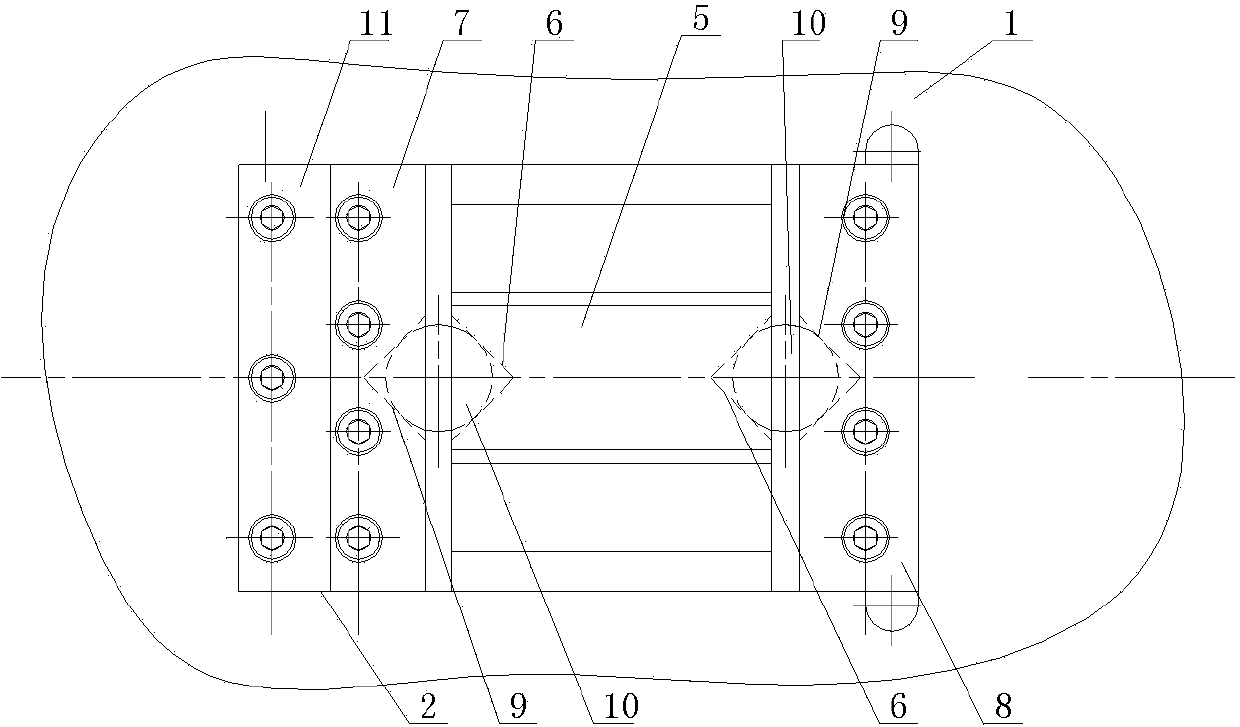

[0009] See figure 1 , figure 2 , which includes a slide plate 1, a linear guide groove (not shown in the figure, which belongs to the existing mature structure), a nut seat 3, and a screw rod 4. The slide plate 1 is clamped in the linear guide groove 2, and the screw rod 4 runs through the nut seat 3. Threaded holes, the bottom of the slide plate 1 is equipped with a nut seat 3, the upper end surface of the nut seat 3 is tightly connected with a moving plate 5, the front end and the rear end of the moving plate 5 are respectively provided with conical positioning holes 6 concave inward, and the moving plate 5 The corresponding positions of the cone positioning holes 6 are respectively provided with a front fixing plate 7 and a rear fixing plate 8, and the positions of the front fixing plate 7 and the rear fixing plate 8 facing the corresponding cone positioning holes 6 are respectively provided with concave cones. There is a gap between the corresponding position of the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com