Loose sand loading pre-compaction construction method for cast-in-situ concrete beam form steel pipe support

A technology of concrete beams and steel pipe supports, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult preloading of beam formwork supports, improve stability and safety, reduce height, and ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0037] 1. The preloading construction method of the cast-in-place concrete beam formwork steel pipe support using loose sand loading is realized through the following steps:

[0038] 1) Step 1: Install the loading device - sand tank on the beam formwork support

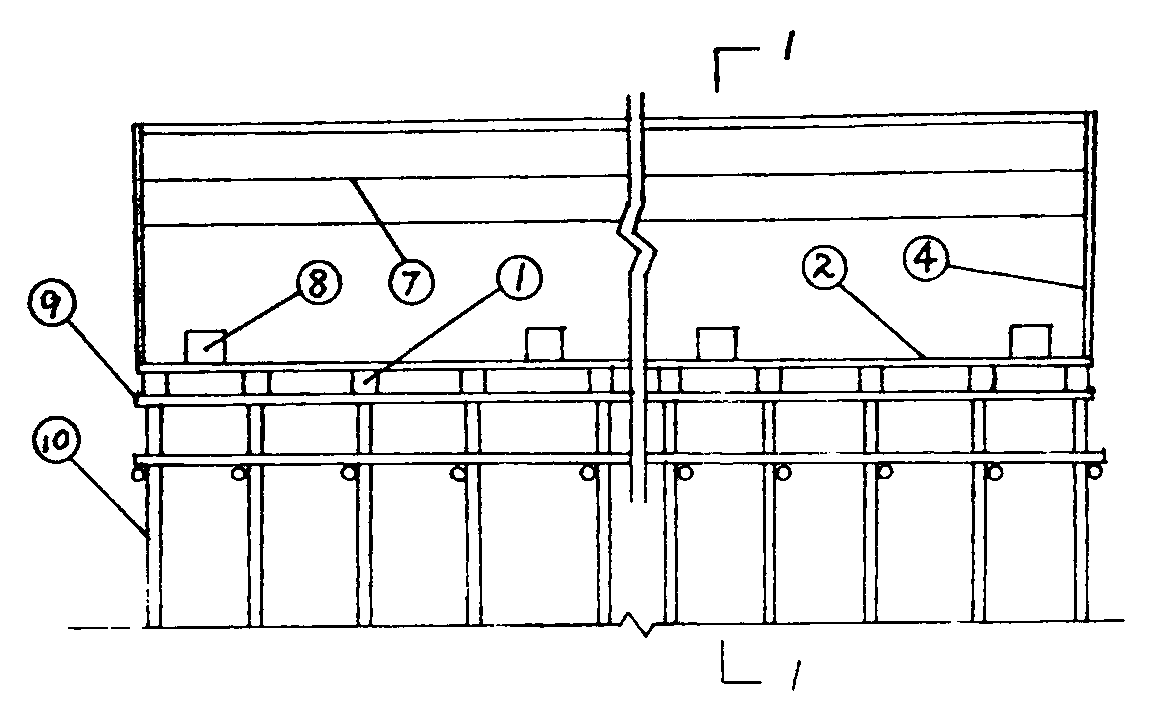

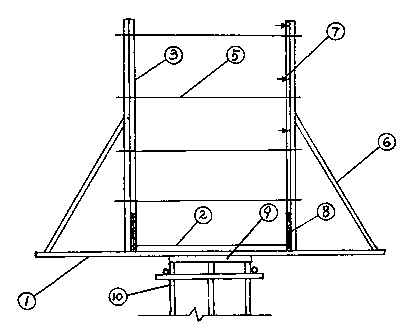

[0039] The loading sand tank is composed of six parts: the bottom beam of the tank, the bottom plate of the sand tank, the end plate of the sand tank, the side plate of the sand tank, the pull bolts and the diagonal brace. See attached figure 1 .

[0040] The beams at the bottom of the tank are made of wood squares or steel pipes, and are placed on the bottom mold of the cast-in-place concrete beams at a certain distance. Lay the bottom plate of the sand tank on the beam at the bottom of the tank. The bottom plate of the sand tank is assembled with wooden boards or small steel molds. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com