Method for silicon micro-resonant type accelerometer temperature compensation

An accelerometer and temperature compensation technology, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring devices, etc., can solve problems such as poor effect and hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

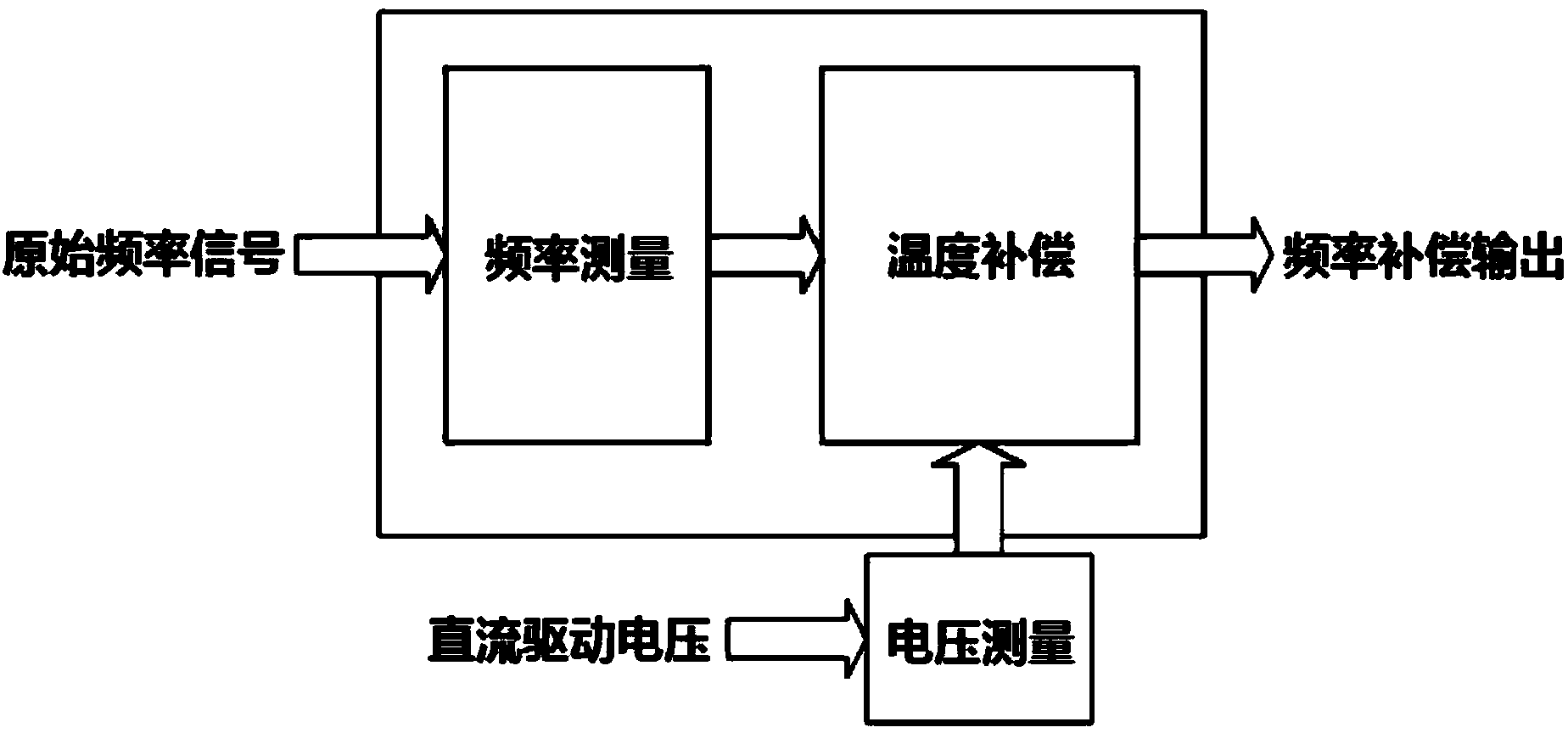

[0050] A method for temperature compensation of a silicon microresonant accelerometer, comprising the steps of:

[0051] (1) In the case of no acceleration signal input, the resonant frequency and DC drive voltage of the silicon microresonant accelerometer are measured within the range of ambient temperature -40 ~ 60 ℃, and the resonance of resonant beam 1 and resonant beam 2 is obtained. A monotonic relationship curve of frequency changing with temperature and a monotonic relationship curve of DC driving voltage changing with temperature; the silicon microresonant accelerometer has two resonant beams, which are respectively recorded as resonant beam 1 and resonant beam 2; specifically include the following steps:

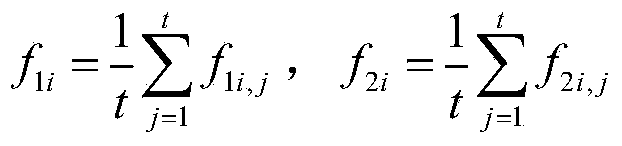

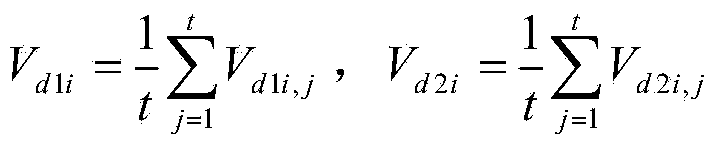

[0052] (11) Calibrate s temperature points within the range of ambient temperature -40-60°C; for example, take 10°C as the temperature interval, divide the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com