A method for temperature compensation of quartz resonant accelerometer

An accelerometer and temperature compensation technology, which is used in the measurement of acceleration, speed/acceleration/shock measurement, instruments, etc., can solve problems such as poor effect and inability to real-time, and achieve the effect of low temperature compensation cost and controllable precision temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

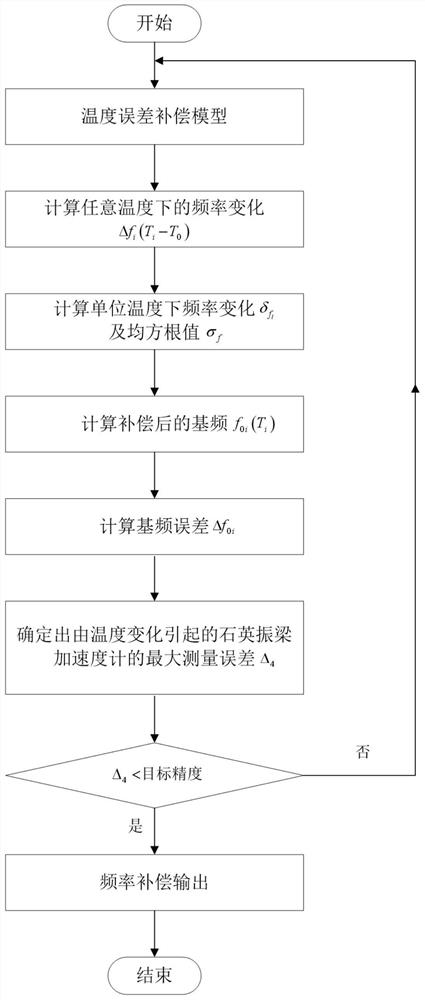

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] combine figure 1 , a temperature compensation method for a quartz resonant accelerometer, the quartz resonant accelerometer is placed in a high and low temperature constant temperature control box, and in the case of no acceleration signal input, any temperature is maintained within the working range of the box temperature -30°C to 80°C constant. In order to balance the temperature in the temperature control box and reduce the influence of the temperature gradient on the test data, first lower the temperature in the temperature control box to -20°C, keep it warm for 30 minutes, then increase the temperature, and keep warm at each temperature point For 30 minutes, take n temperature measuring points for testing. Including the following steps:

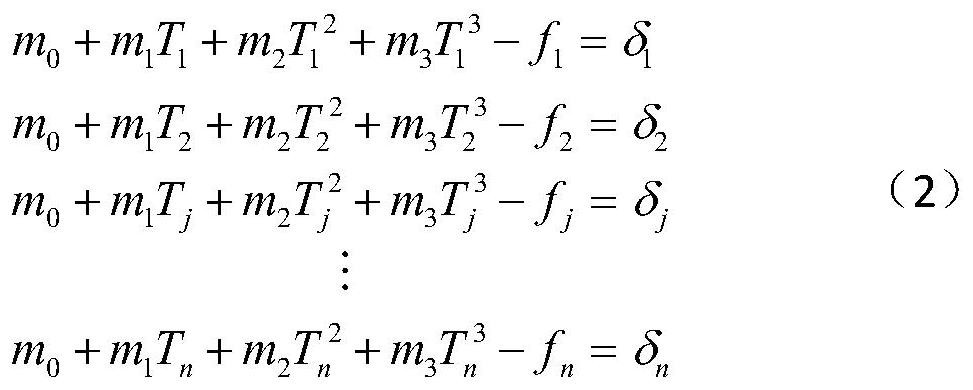

[0041] Step 1: Build a temperature error compensation model for the static temperature characteristics of the acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com