Customer demand-oriented product module planning method

A technology for customer needs and products, applied in special data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as not paying attention to customer needs and being susceptible to subjective influences, and achieve the effect of avoiding subjective influences and simplifying the planning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

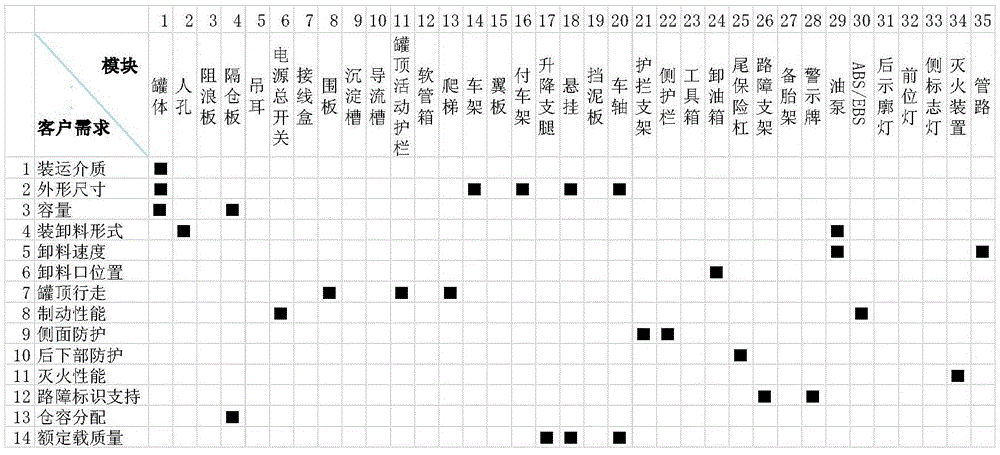

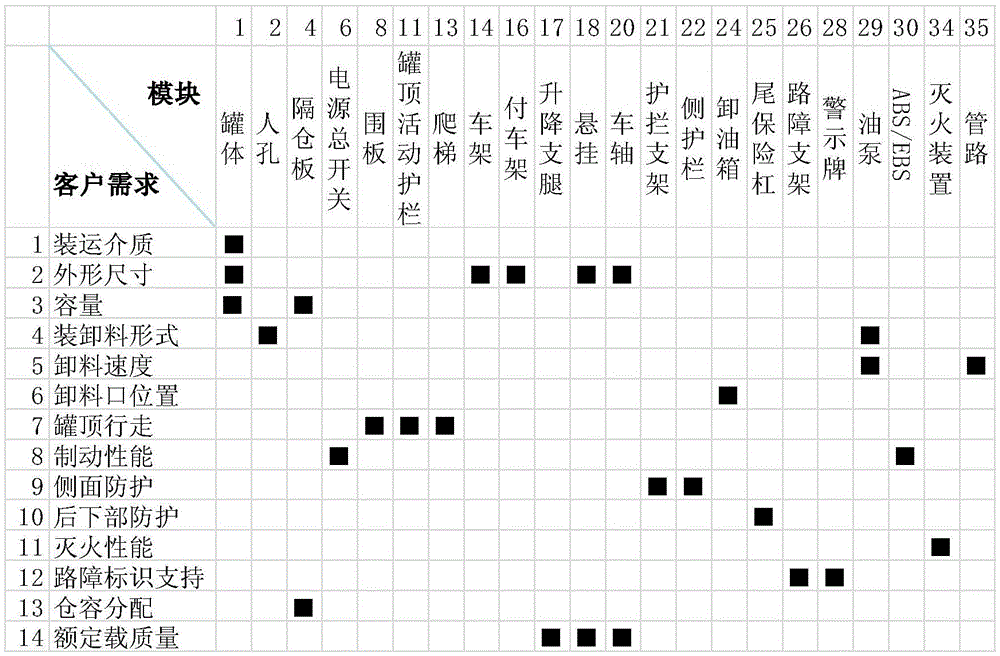

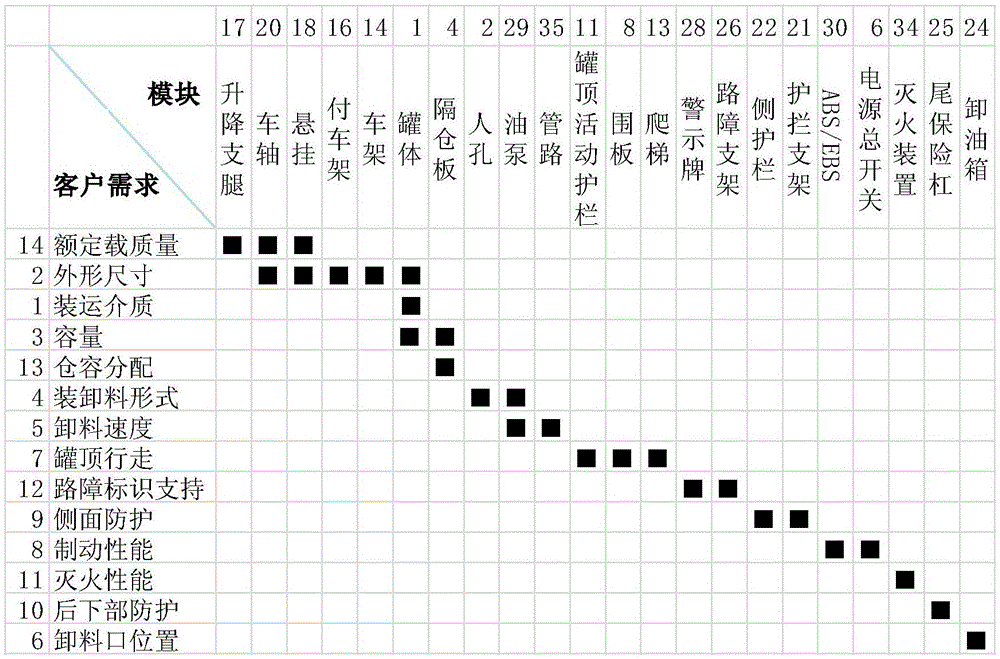

[0041] Example: A certain tank type semi-trailer includes 35 functional modules. For this type of tank semi-trailer, there are a total of 14 customer requirements.

[0042] Due to the close geometric correlation between modules, the modules cannot be divided by geometric correlation. The traditional division method is to divide the modules into three categories according to the main functional modules and their related accessories: tank body and accessories, frame and accessories, pipeline and accessories. Using this kind of planning scheme, when the customer's demand is related to both the tank body and the frame, the two departments need to coordinate and make adjustments together, and the work efficiency is low.

[0043] The technical solution of the present invention to solve its technical problem is: the described a kind of customer demand-oriented product module planning method, first establishes the DDM matrix according to the corresponding relationship between custome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com