Heat dissipation structure possessing double wind directions

A heat dissipation structure and wind direction technology, applied in cooling/ventilation/heating transformation, etc., can solve the problems of insufficient use, insufficient space, and airflow that cannot be directly blown to the electronic component and its surroundings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable the examiner to clearly understand the content of the present invention, only the following descriptions are provided together with the drawings, please refer to them.

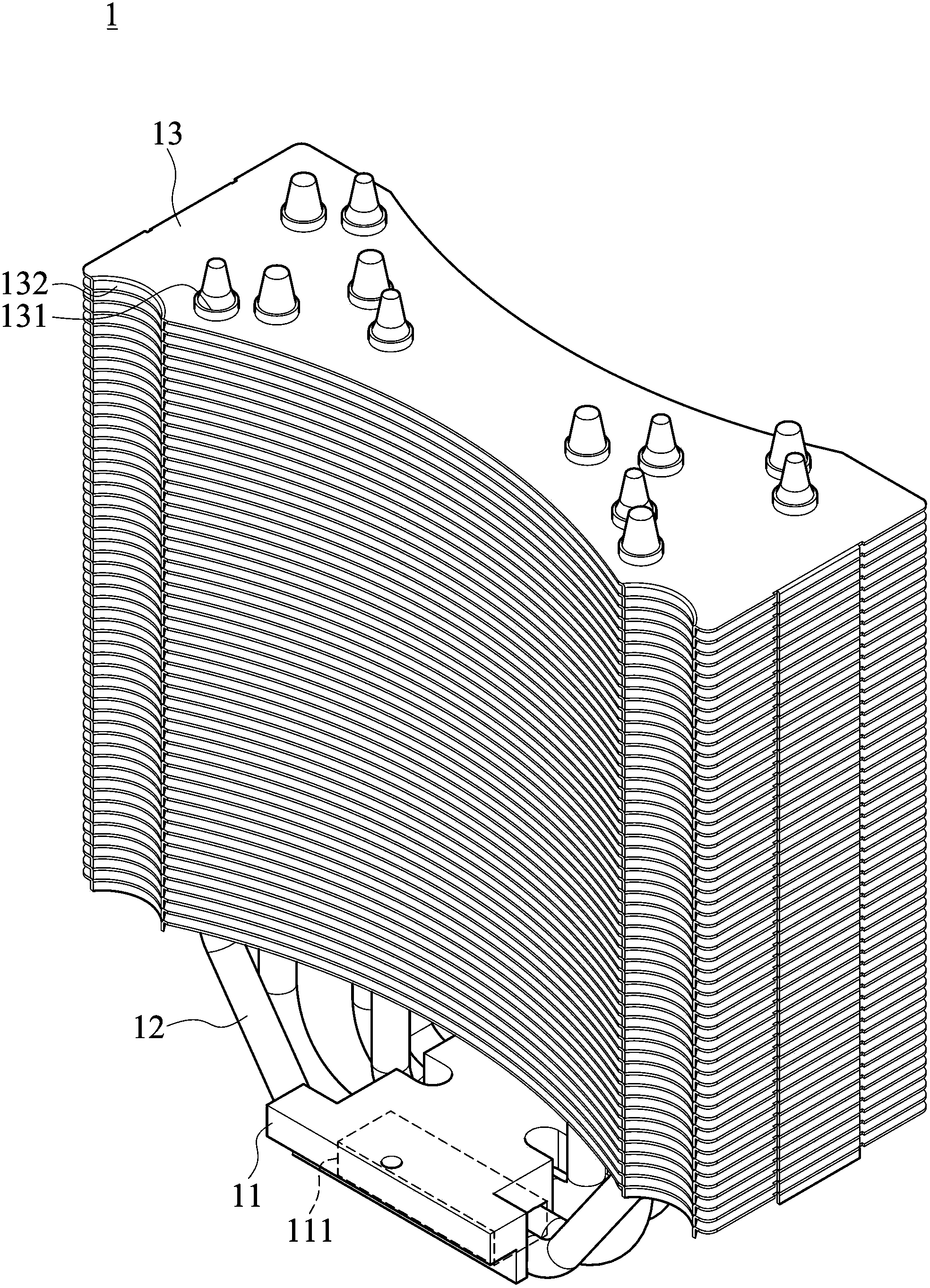

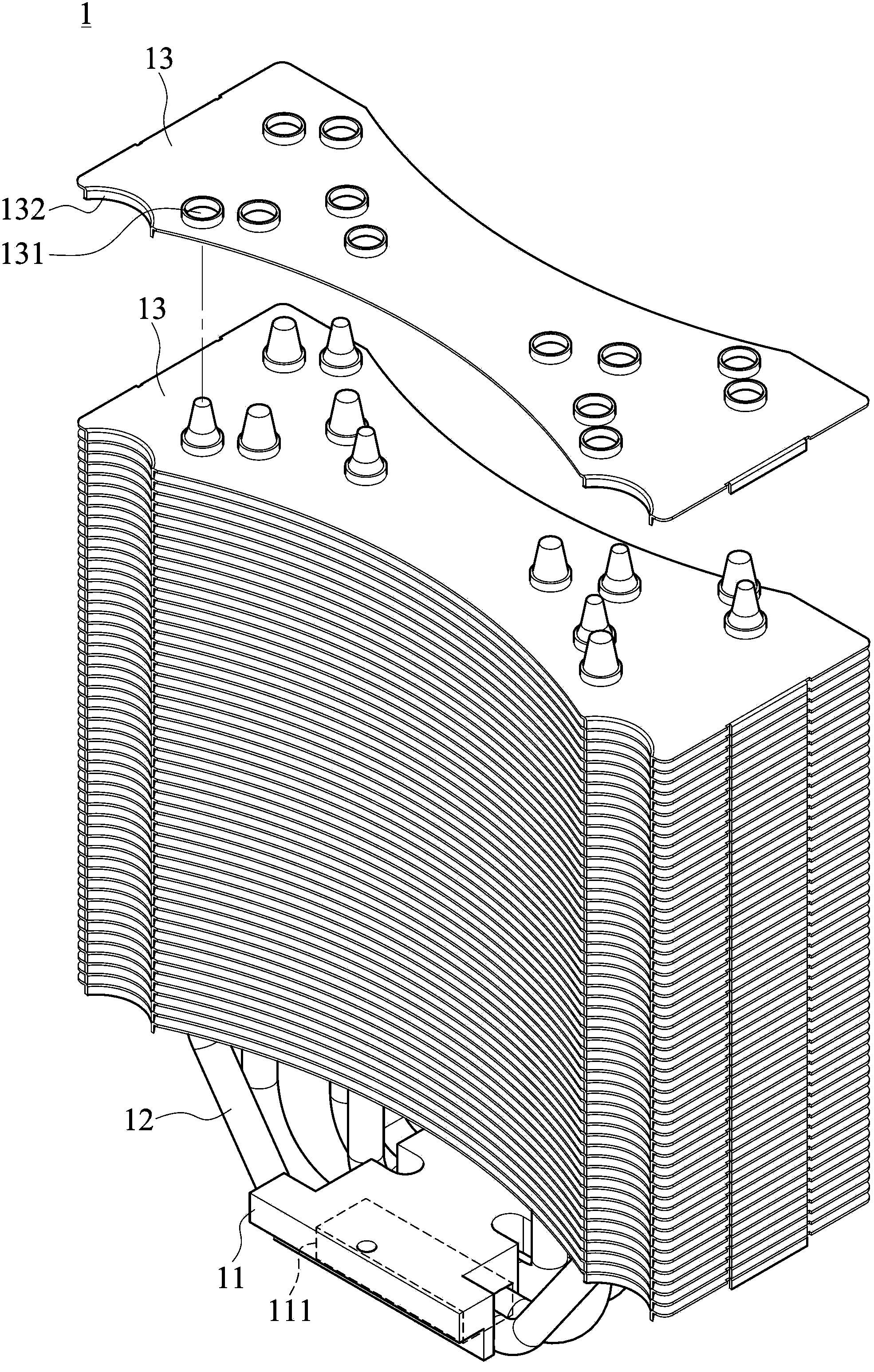

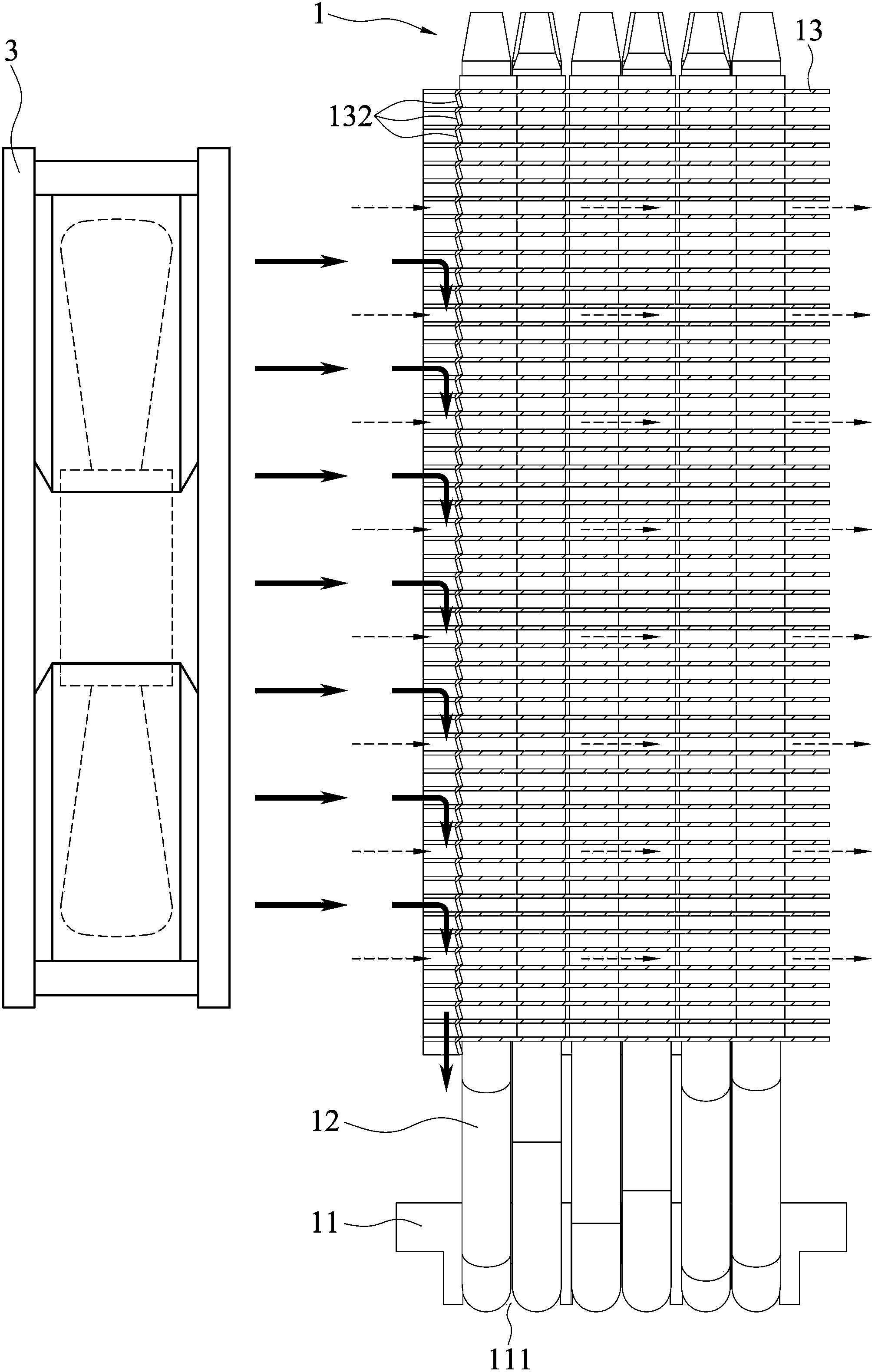

[0025] see figure 1 , 2 Shown is the three-dimensional structure diagram and its three-dimensional exploded view of the preferred embodiment of the present invention. As shown in the figure, the heat dissipation structure 1 with dual wind directions of the present invention is for installation on an electronic component 2, and a wind source 3 is provided on one side thereof. The heat dissipation structure 1 with double wind directions includes a base 11, multiple A branch heat pipe 12 and a plurality of cooling fins 13 .

[0026] The base 11 is a rectangular block-shaped structure made of a heat-conducting metal material such as aluminum or copper through casting or stamping, and one side thereof is disposed on the electronic component 2 . Furthermore, the base 11 can be provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com