Double-layered plow type sweeper

A technology of a sweeper and a double-layer plow, applied in the field of sweepers, can solve the problems of easily damaged belts, the single-layer plow sweeper is not easy to clean, the sweeper is scrapped, etc., and the effect of easy removal is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

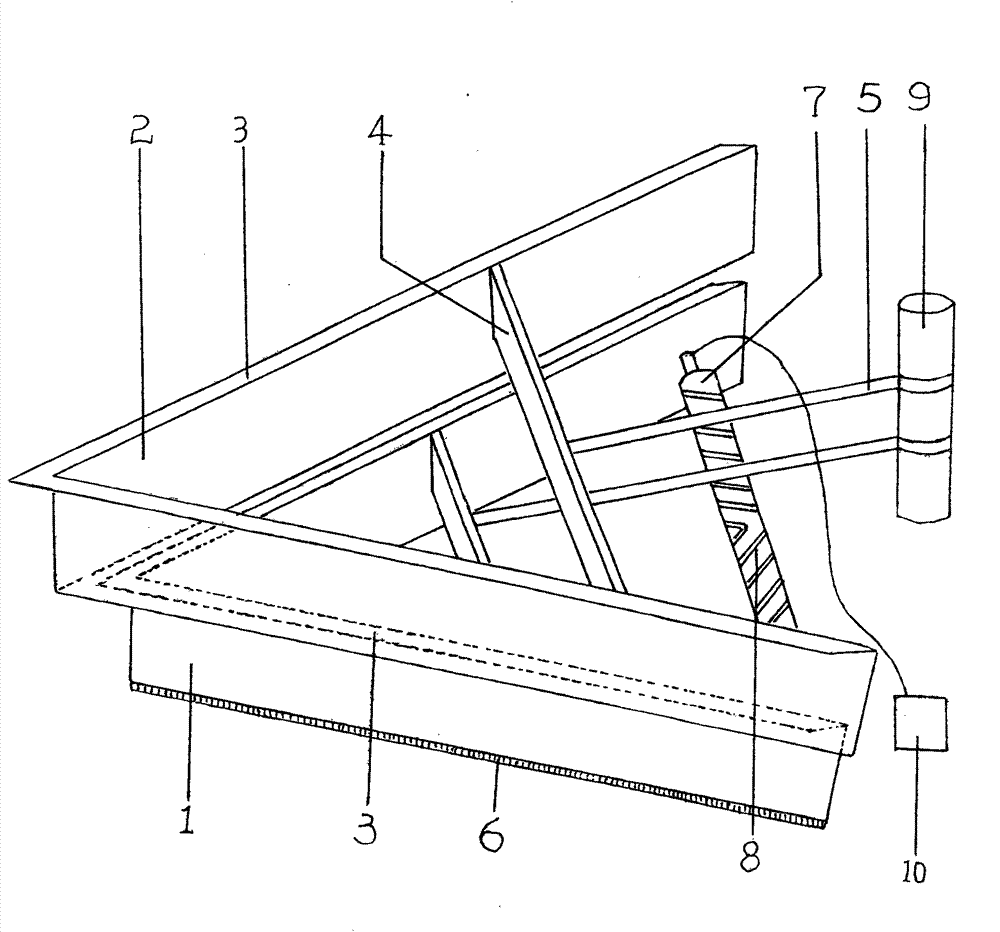

[0007] A double-layer plow cleaner, comprising a first plow share (1), a second plow share (2), blades (3), connecting plates (4), connecting rods (5), and brush pads (6) , brush roller (7), spiral adhesive tape (8), support (9), driving device (10), the first plow share (1), the top of the second plow share (2) is provided with sheet (3), the second The volume of the plowshare (2) is smaller than that of the first plowshare (1), the blades (3) of the first plowshare (1) are inserted into the bottom of the second plowshare (2), and the first plowshare (1) A brush pad (6) is provided on the contact surface between the bottom and the belt conveyor, and a brush roller (7) is arranged on the first plowshare (1), and the brush roller (7) sends spiral tapes (8) on both sides with the middle of the roller body as the boundary, The brush roller (7) is controlled to rotate by the driving device (10), and each plow share is connected and supported by a connecting plate (4), and a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com