Carbon fiber sheet prestressed tensioning device and tensioning method

A carbon fiber sheet and tensioning device technology, which is applied in building maintenance, building material processing, construction, etc., can solve the problem of damage to concrete structures, concrete structure damage, and tension values that cannot reach the design tensile strength value of carbon fiber sheets, etc. problem, achieve the effect of reducing the loss rate and improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The existing prestressed tensioning device needs to chisel out the original concrete structure in a large area and depth, causing damage to the concrete structure; and the jack needs to sink into the concrete structure to destroy the concrete structure, and the position of the jack is also affected by the beam body. Influenced by the size of the end of the structure; during the tensioning process, the carbon fiber sheet is subjected to eccentric tension, so that the tension value cannot reach the design tensile strength value of the carbon fiber sheet. Embodiments of the present invention provide a carbon fiber sheet prestressed tensioning device and a tensioning method.

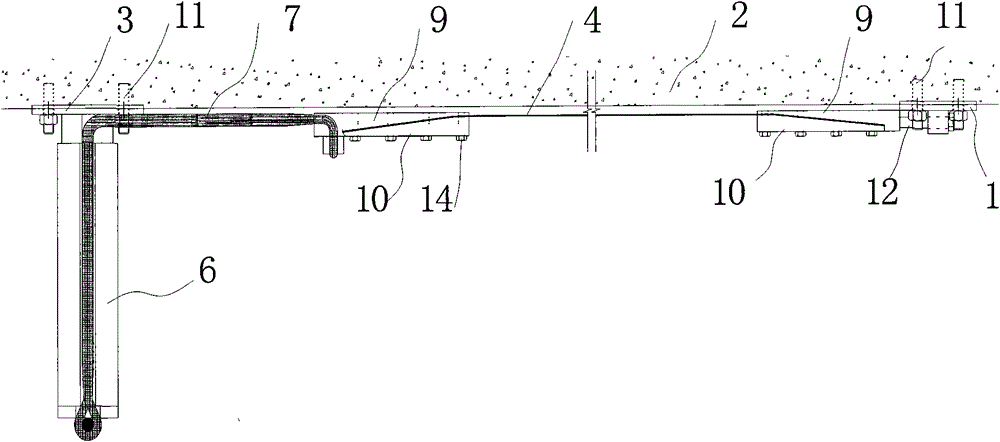

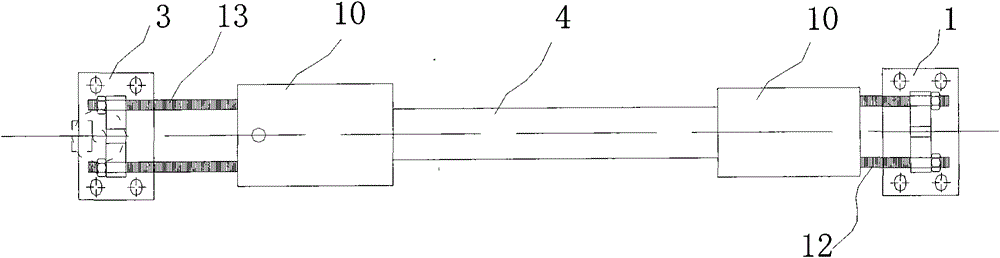

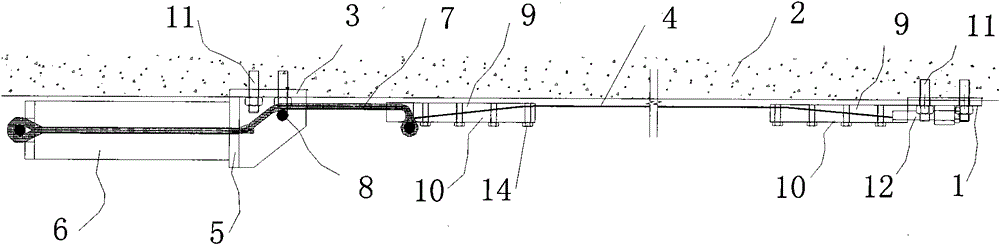

[0028] Such as figure 1 with figure 2 As shown, the carbon fiber sheet prestressed tensioning device includes: a fixed end fixing device, including a fixed end fixing seat 1, and the fixed end fixing seat 1 is fixedly installed on the concrete structure 2;

[0029] The fixed end anchor clamps and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com