Self-anchored prestressed fiber reinforced composite cloth reinforced concrete device and method

A technology of composite material cloth and fiber reinforcement, which is applied in bridge reinforcement, building maintenance, bridge maintenance, etc., can solve the problems of changing the original structure deformation, uneven force application, large prestress, etc., so as to reduce the loss of prestress and avoid Effect of eccentric tension and high efficiency coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

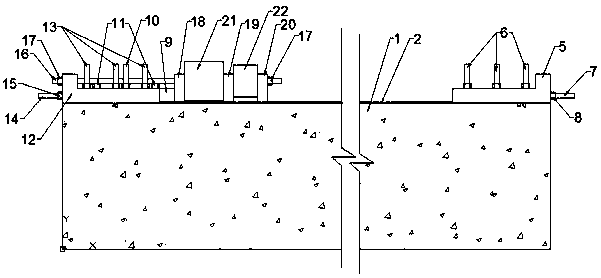

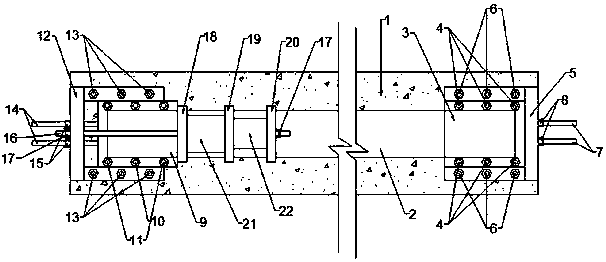

[0034] The technical features of a self-anchored prestressed fiber-reinforced composite material cloth reinforcement concrete device and its method for concrete reinforcement of the present invention will be further described below in conjunction with the accompanying drawings and examples.

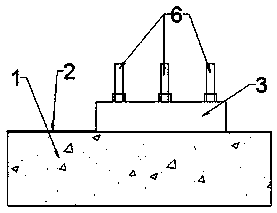

[0035]The device for reinforcing concrete with prestressed fiber reinforced composite material cloth of the present invention comprises fiber cloth 2, fixed end clamp 3, fixed end clamp anchor bolt 4, fixed end steel channel 5, fixed end anchor bolt 6, fixed end fixed screw rod 7, fixed end End nut 8, tension end fixture 9, tension end fixture anchor bolt 10, tension end fixture bolt 11, tension end steel channel 12, tension end anchor bolt 13, tension end fixing screw 14, tension end nut 15. Tension screw 16, tension screw nut 17, first baffle plate 18, second baffle plate 19, third baffle plate 20, jack 21, force sensor 22, the concrete member 1 to be reinforced is pre-prepared at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com