Terminal part for storage battery, resin winding terminal for storage battery, manufacturing method thereof, storage battery including terminal part, and automobile equipped with storage battery

A manufacturing method and storage battery technology, applied to small-sized batteries/battery packs, battery pack parts, batteries, etc., can solve problems such as nut fixing methods are not specifically recorded, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

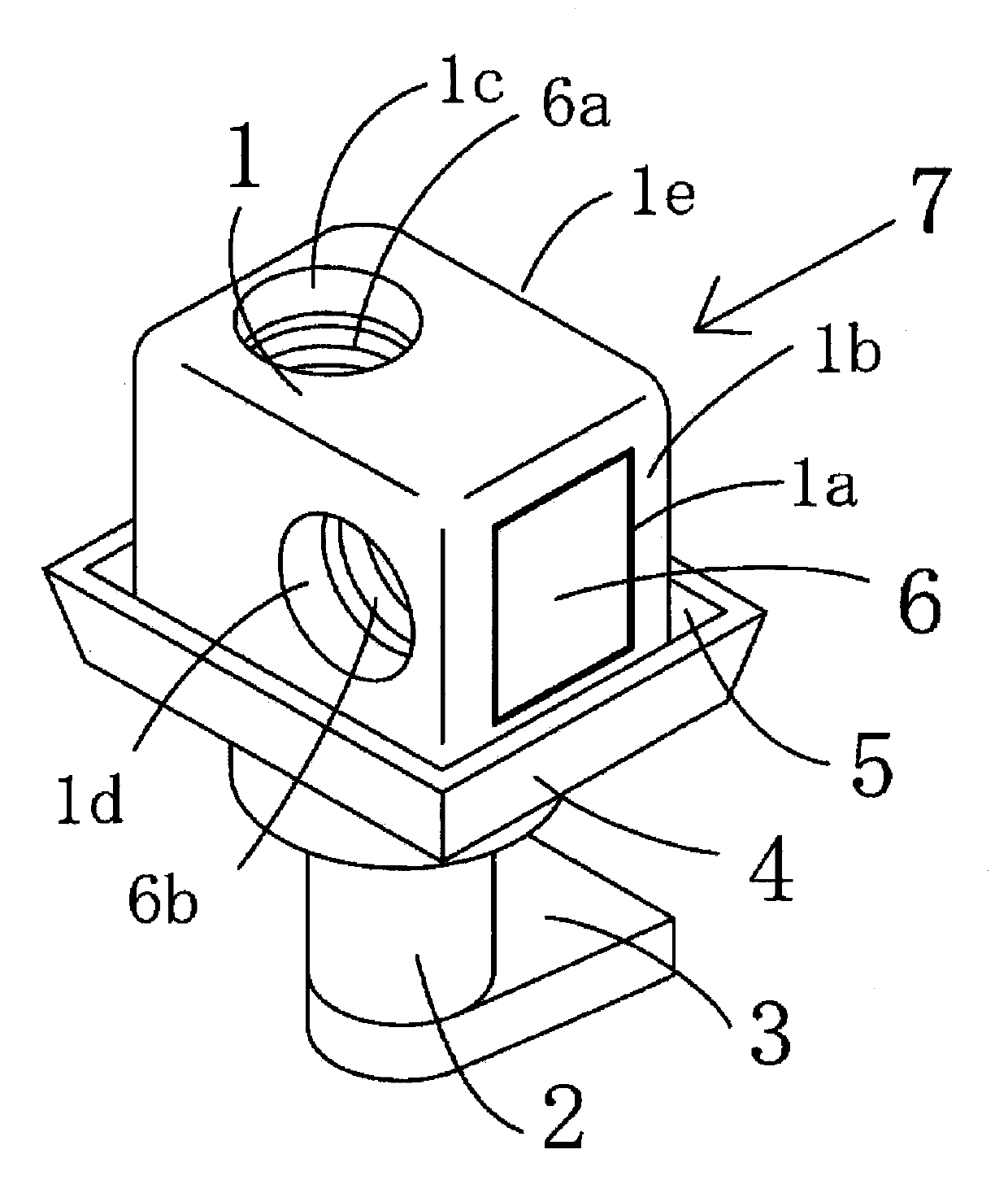

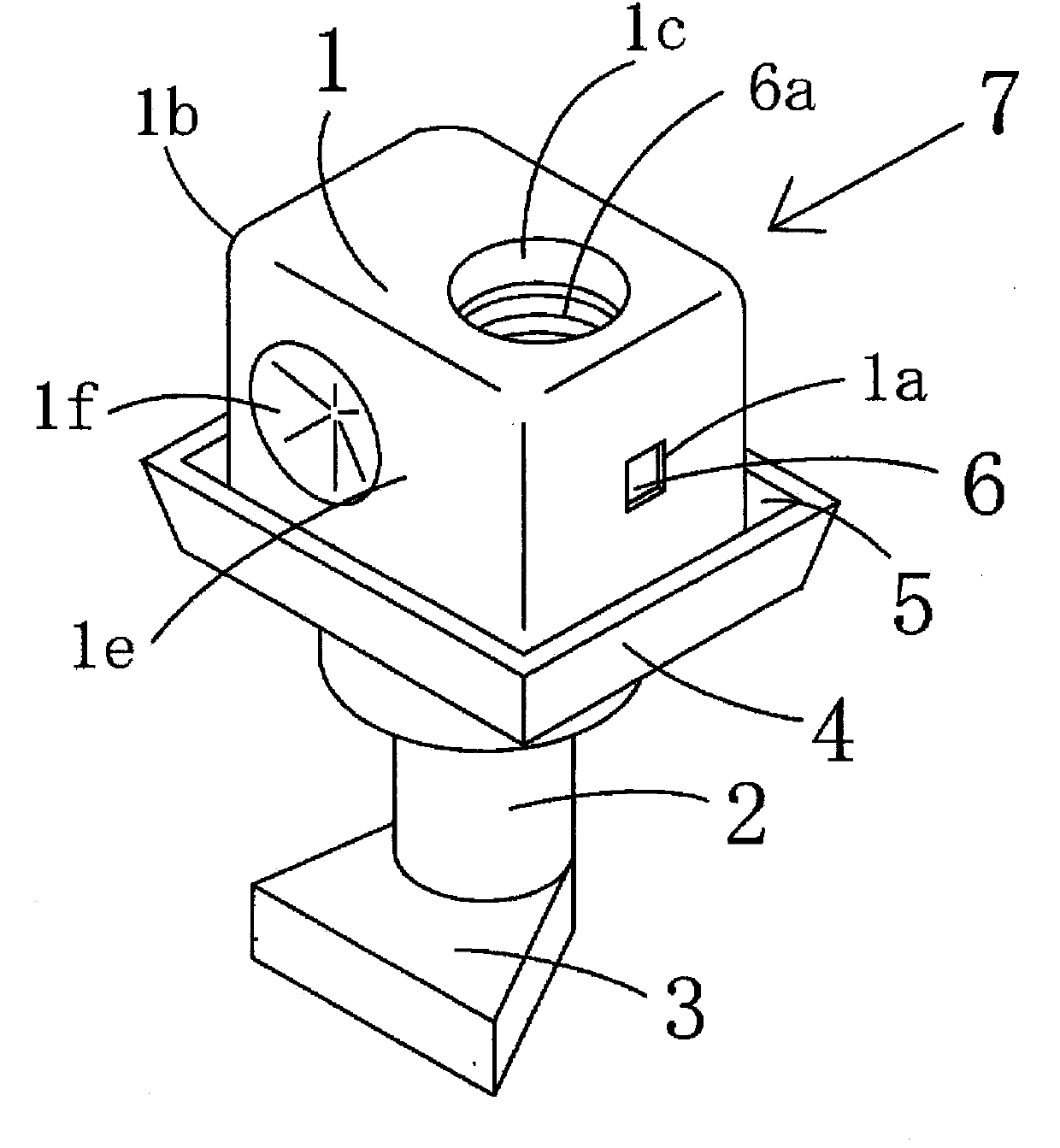

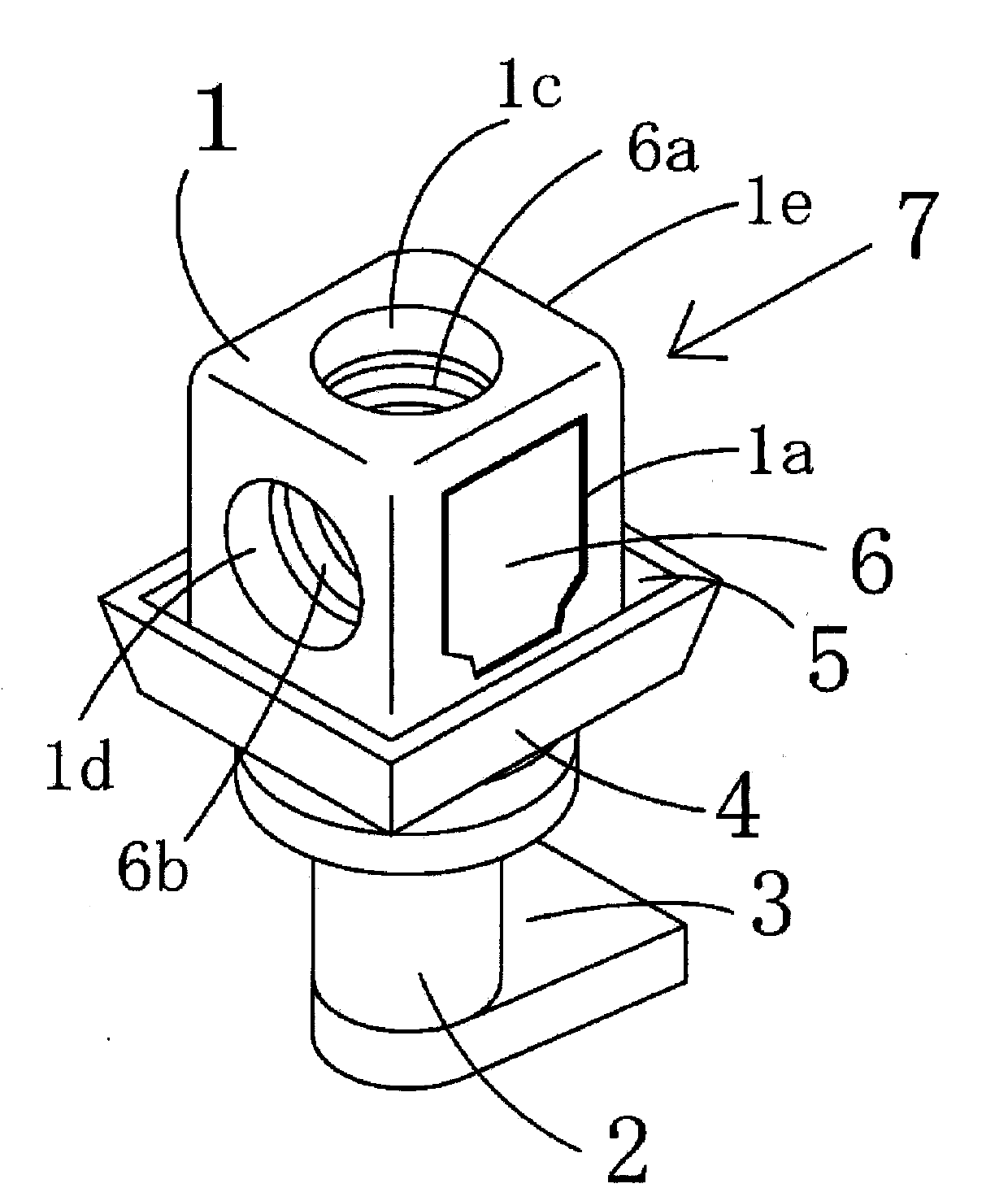

[0067] Embodiment 1 (example applied to the resin winding terminal 7) of the battery terminal part of this invention is shown in FIG.1(a) and FIG.1(b).

[0068] The cuboid battery terminal 1 has a cavity 1a for inserting the nut 6 and an insertion opening 1b, and the cavity 1a for inserting the nut 6 penetrates from the insertion 1b on the right side toward the left side in FIG. 1(a). However, as shown in FIG. 1(b), it is preferable to leave a wall on the side opposite to the insertion 1b so that the nut 6 does not come out. In addition, a bolt insertion hole 1c is drilled from the upper surface toward the cavity 1a, and a bolt insertion hole 1d is drilled from the front surface toward the cavity 1a.

[0069] In Embodiment 1, in order to simultaneously connect external leads at two or more locations, the bolt insertion holes 1c on the upper surface and the bolt insertion holes 1d on the front surface are formed at positions that do not cross each other in the cavity 1a, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com