Self-adaptive cover and seam mechanism used in multi-stamp stamping machine

A self-adaptive, stamping technology, applied in printing, stamping and other directions, can solve the problem that the automatic stamping machine cannot adapt to the stamping and seam stamping, and achieve the effect of reducing workload and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

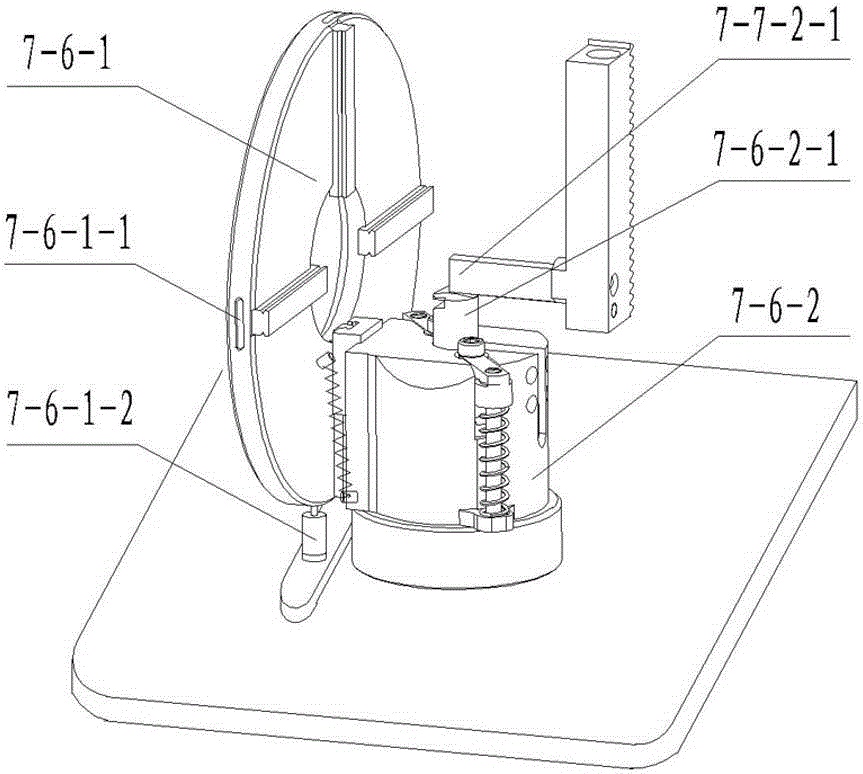

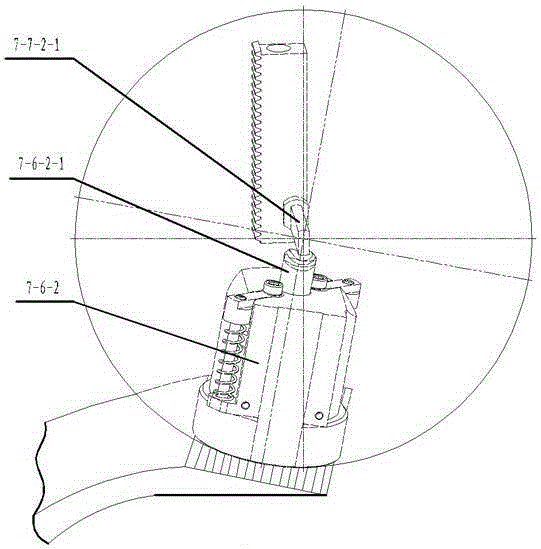

[0017] The present invention relates to a self-adaptive cap-riding stamp mechanism used in a multi-stamp stamping machine, the structure includes a vertical push-down stamp head drive device positioned on the frame and a position-limiting disc 7-6-1 The upper chapter body assembly 7-6-2, the driving pressure handle 7-7-2-1 in the chapter head driving device is in phase with the driven pressure rod 7-6-2-1 in the chapter body assembly 7-6-2 Contact, the station disk 7-6-1 is limited at the design station by means of the rotating shaft, and has a degree of freedom of 2°-5° swing, the driving pressure handle 7-7-2-1 in the structure of the chapter head driving device The lower end surface is a flat or arc-shaped convex surface, and the upper end surface of the driven pressing rod 7-6-2-1 in the chapter body assembly 7-6-2 is an arc-shaped concave surface.

[0018] The arc-shaped convex surface of the lower end surface of the driving pressure handle 7-7-2-1 is tangent to the arc-s...

Embodiment 2

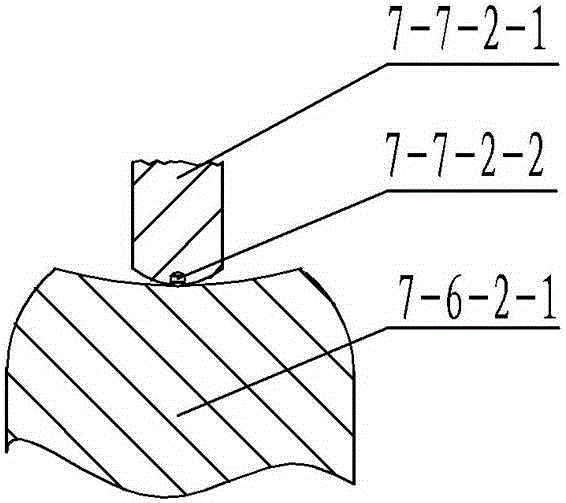

[0024] The difference from Embodiment 1 is that the lower end surface of the driving press handle 7-7-2-1 is provided with a needle rolling mechanism 7-7-2-2, and the needle rolling mechanism 7-7-2-2 and the chapter body assembly 7-6 The arc-shaped concave surface on the upper end surface of the driven pressure rod 7-6-2-1 in -2 is in line contact.

[0025] During specific implementation, when the chapter body assembly 7-6-2 moves downward under the drive of the vertical push-down chapter head driving device and encounters an inclined surface, the pressing handle 7-7-2 is driven by means of the needle roller mechanism 7-7-2-2. The lower end surface of 7-2-1 slides relative to the upper end surface of the driven pressure rod 7-6-2-1 in the chapter body assembly 7-6-2, thereby more flexibly realizing the chapter body assembly 7-6-2, and The self-adaptive deflection of the station disc 7-6-1 facilitates stamping on the slope.

[0026] This embodiment is applied to a multi-stamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com