Vertical cabinet type air-conditioner

An air conditioner and vertical cabinet technology, which is applied in the field of air conditioners, can solve the problems of narrowing the air supply angle range, weak wind, and difficulty in directing the wind direction to the front, so as to increase the air supply angle, improve comfort, and improve comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

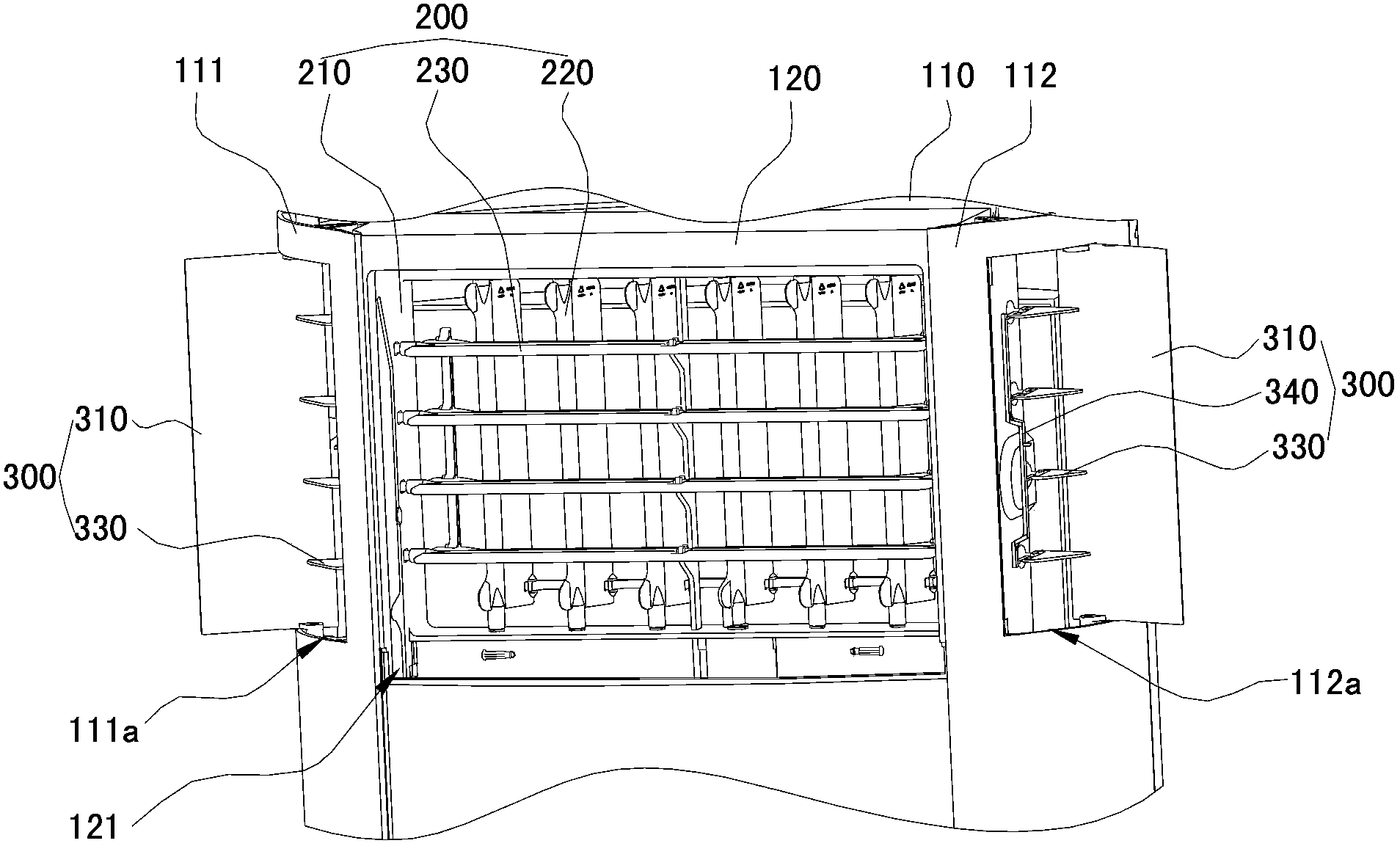

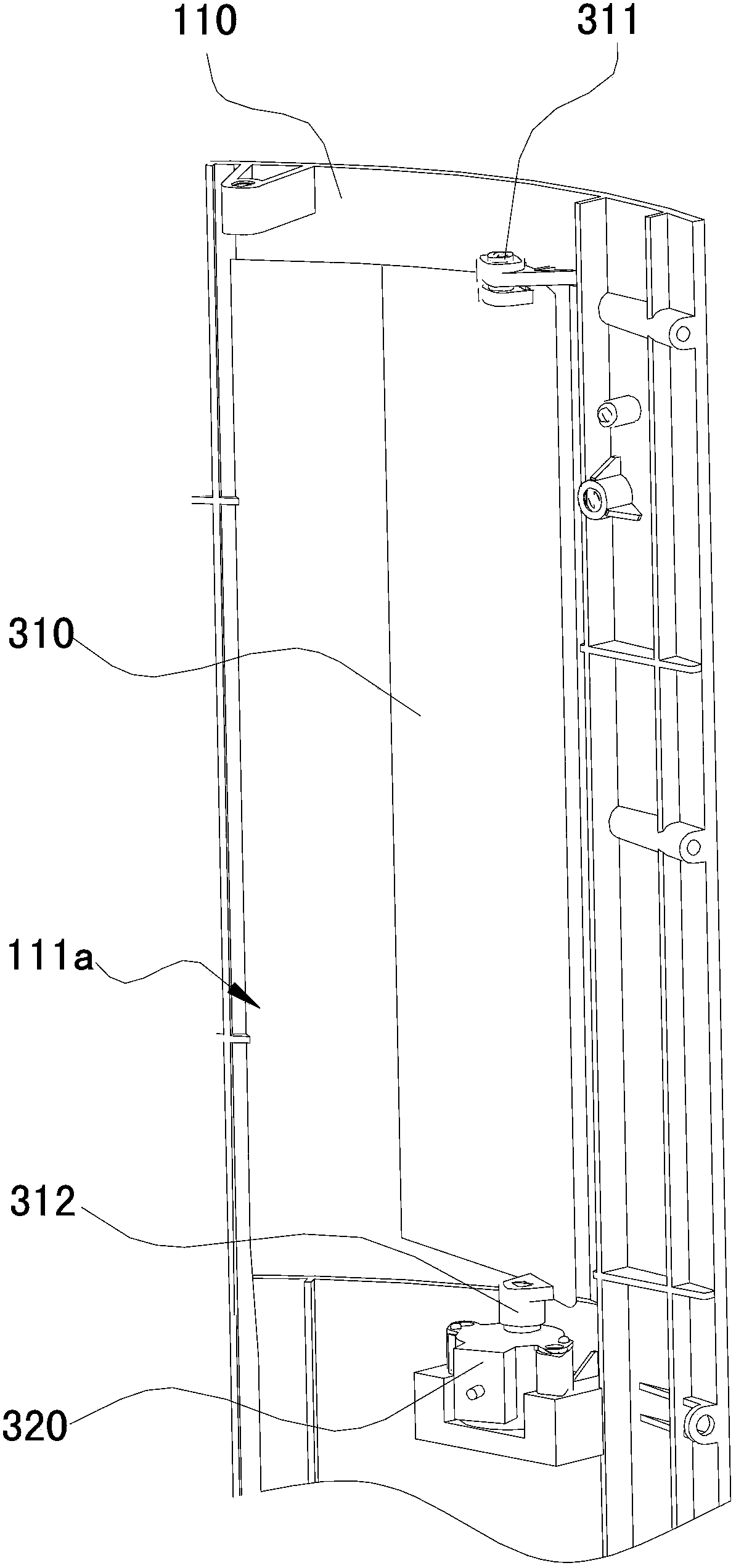

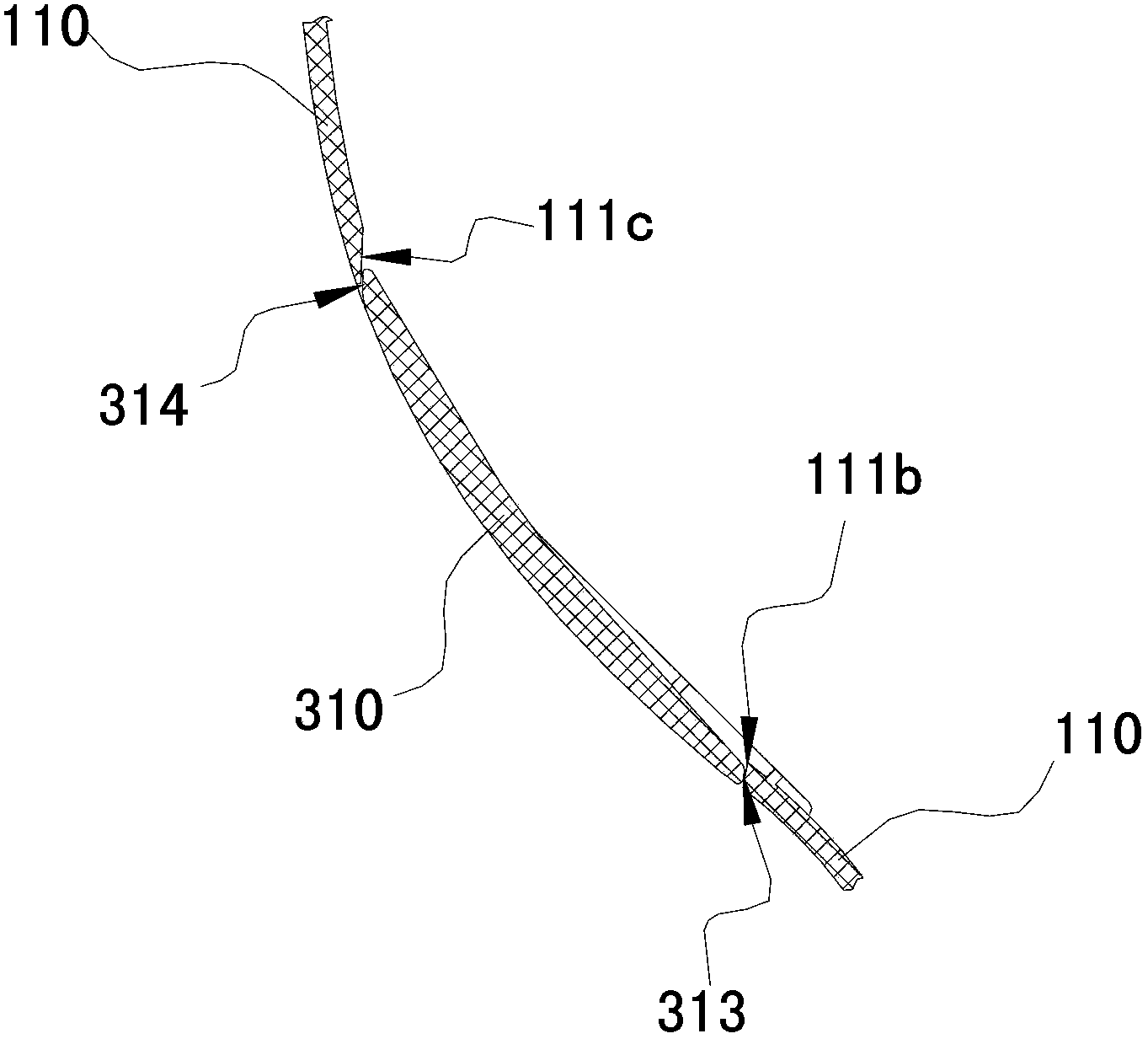

[0025] The structure of the vertical cabinet air conditioner in one of the embodiments of the present invention is as follows: figure 1 As shown, a front air outlet 121 and a side air outlet 111a are respectively provided on the front and side of the casing 100, and front air guides for guiding the front air outlet are respectively provided at the front air outlet 121 and the side air outlet 111a. The component 200 and the side air guiding component 300 for guiding the side air. In this embodiment, the casing 100 includes a casing 110 and an air outlet panel 120, the front air outlet 121 is arranged on the upper part of the air outlet panel 120, and the side air outlet 111a is arranged on the left side panel 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com